Steel structure building beam or pillar node interface

A steel structure building and column joint technology, which is applied in the direction of building structure and construction, can solve the problems of low connection strength, poor precision, laborious assembly, etc., and achieve the effects of easy forming, large bearing capacity, stress and brittleness elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

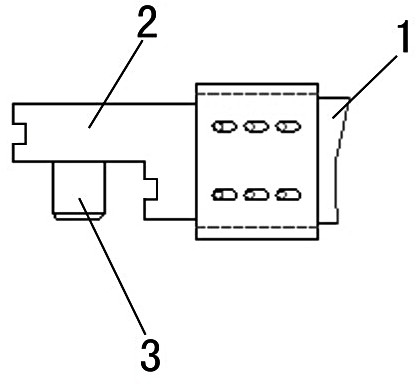

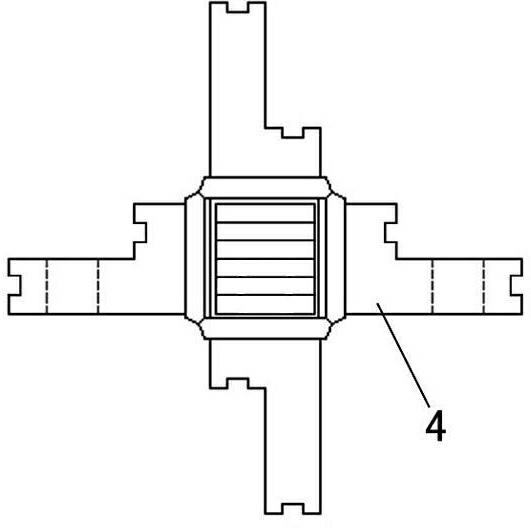

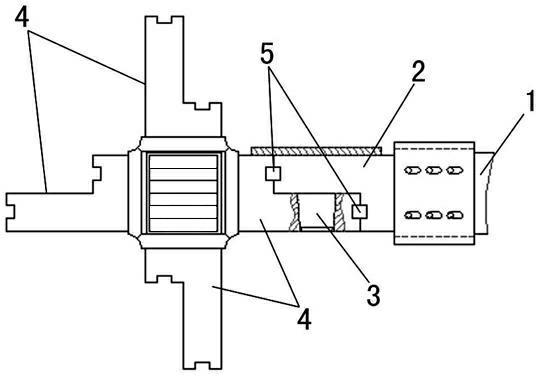

[0020] refer to figure 1 , figure 2 , the interface of the present invention is composed of the joint 2 at the end of the beam or column 1 and the joint seat 4 gathered on the node, wherein the joint lacks half in the transverse direction at the end to form a stepped shape. The shape and size of the joint seat are the same as those of the joint. There are joints integrated with the joint and the connecting tenon 3 of the joint seat on the overlapping surface formed when the joint is docked with the joint seat, and the joint seat has a tenon hole.

[0021] refer to image 3 , Figure 8 , Figure 9 The fastening keys 5 that extend into the components on both sides of the butt surface to prevent the joint and the joint seat from being separated laterally are embedded at the two butt surfaces of the joint and the joint seat that are not on the same cross section. Cover the coaming plate 6 at the interface, and the coaming plate includes three faces with a rectangular cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com