Touch display device and manufacturing method thereof

A technology for a touch display device and a display surface, applied in the field of touch technology, can solve problems such as uneven display brightness and traces, and achieve the effects of eliminating stress and solving deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

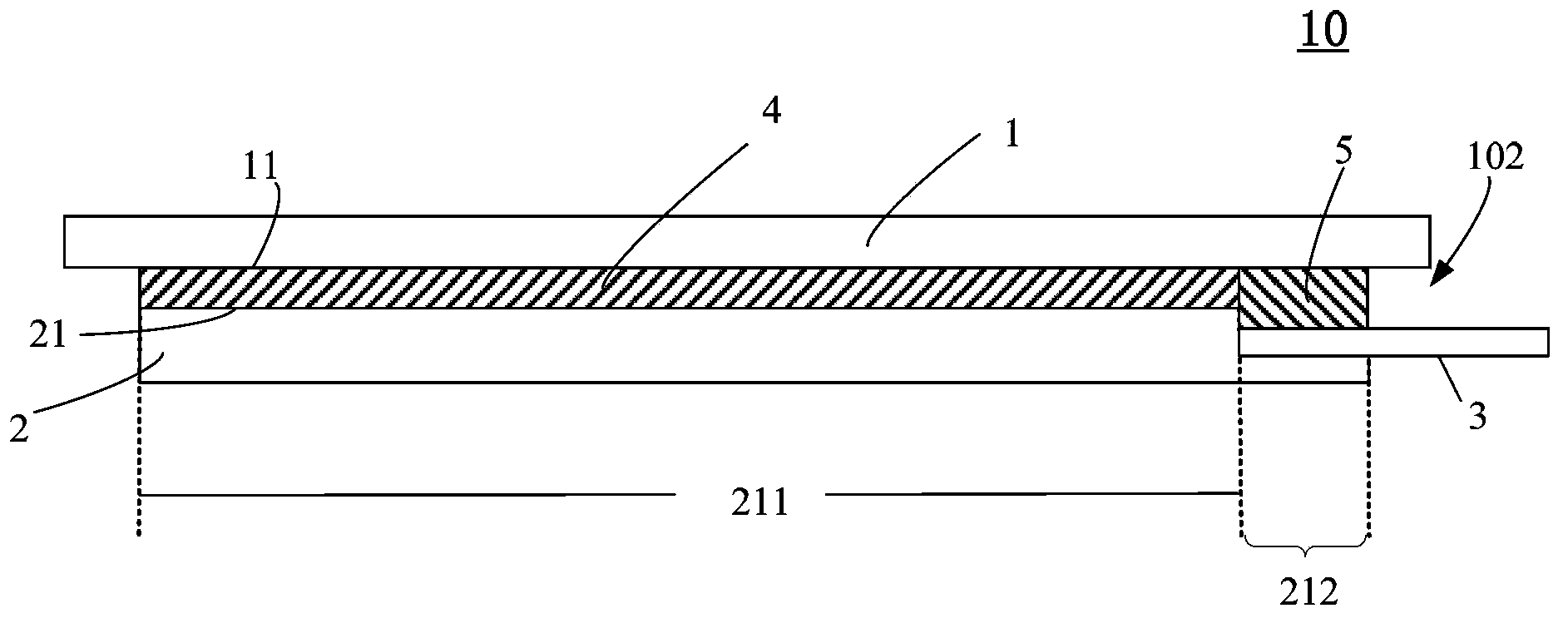

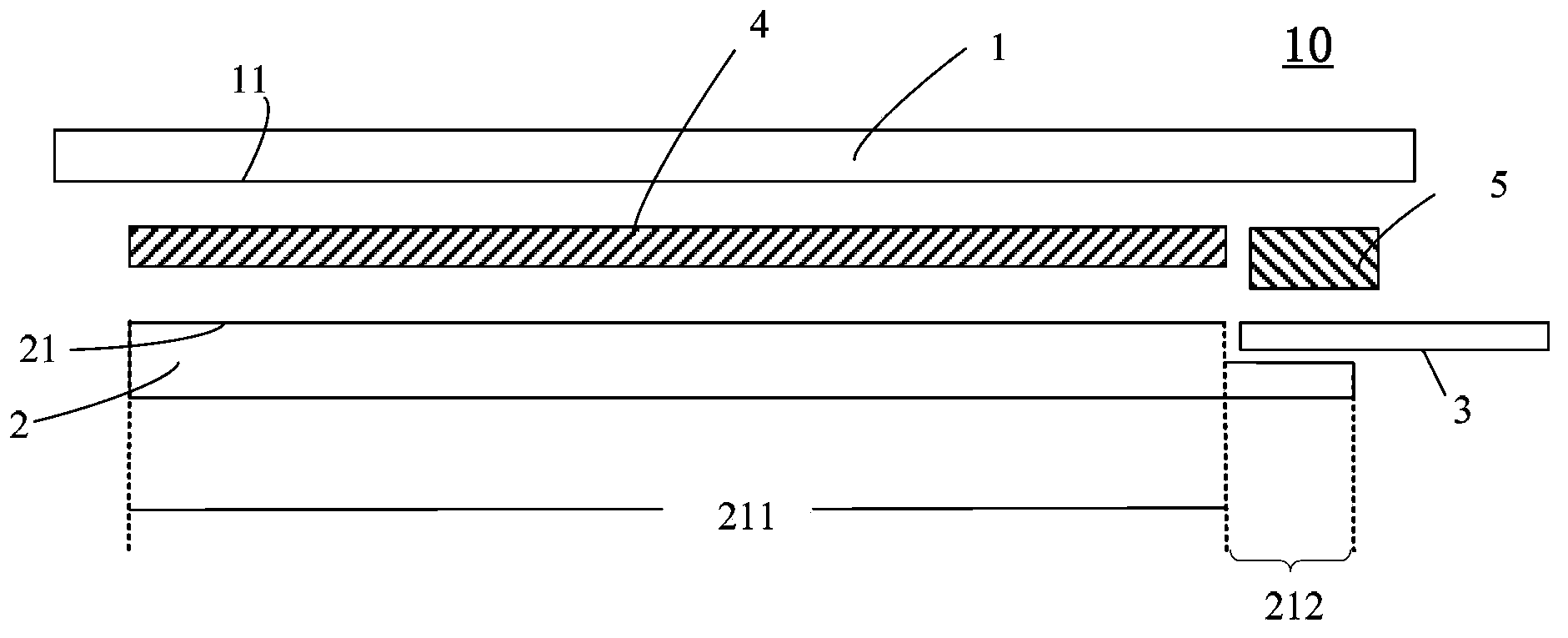

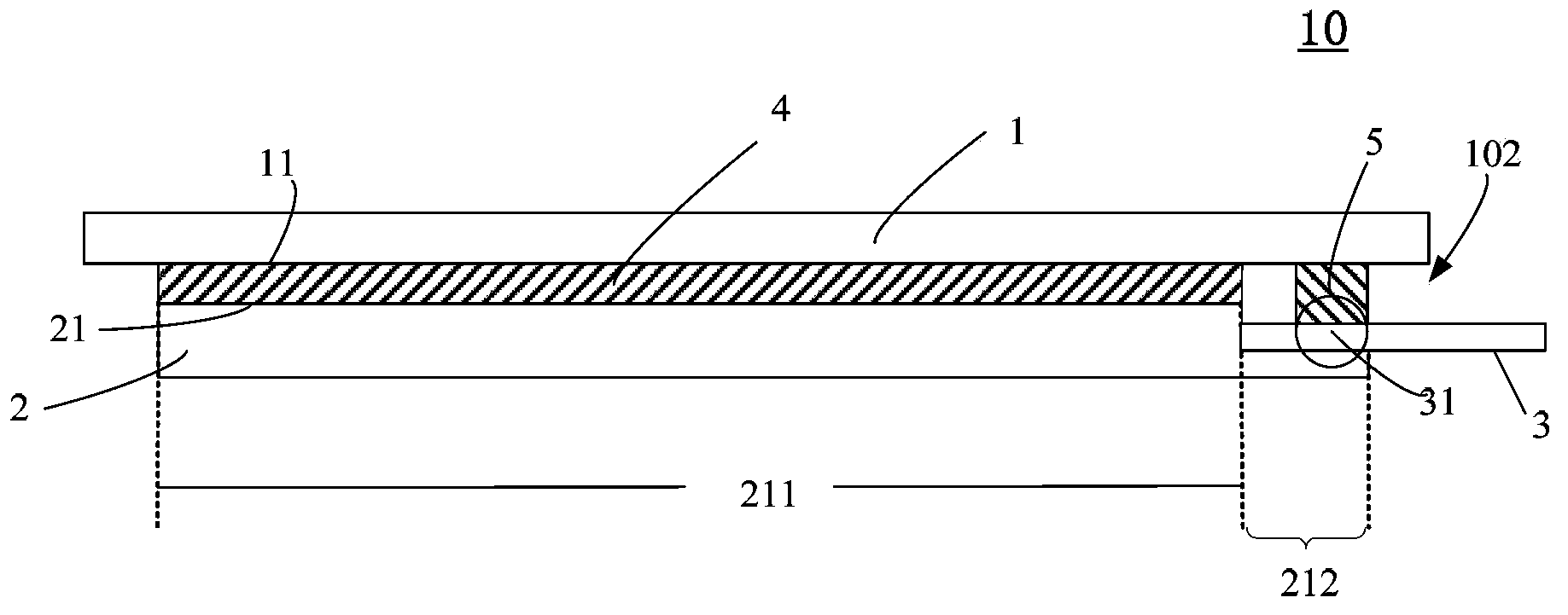

[0039] like figure 1 and figure 2 shown, where figure 1 It is a structural schematic diagram of the first embodiment of the present invention, figure 2 for figure 1 In the exploded view, the touch display device 10 includes a touch module 1 , a display module 2 , a flexible printed circuit board 3 and an adhesive layer 5 . Among them, the touch module 1 includes a bonding surface 11; the display module 2 includes a display surface 21, and the flexible printed circuit board 3 is connected to the edge of the display surface 21, and the bonding surface 11 is arranged opposite to the display surface 21 and 4 For bonding, a gap 102 is formed between the bonding surface 11 and the flexible printed circuit board 3 ; the colloid layer 5 fills the gap 102 to fix the flexible printed circuit board 3 on the bonding surface 11 of the touch panel 1 . In this embodiment, the display surface 21 of the display module 2 is composed of a connection area 212 and a non-connection area 211. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com