Method of manufacturing header tank for heat exchanger and heat exchanger having the header tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

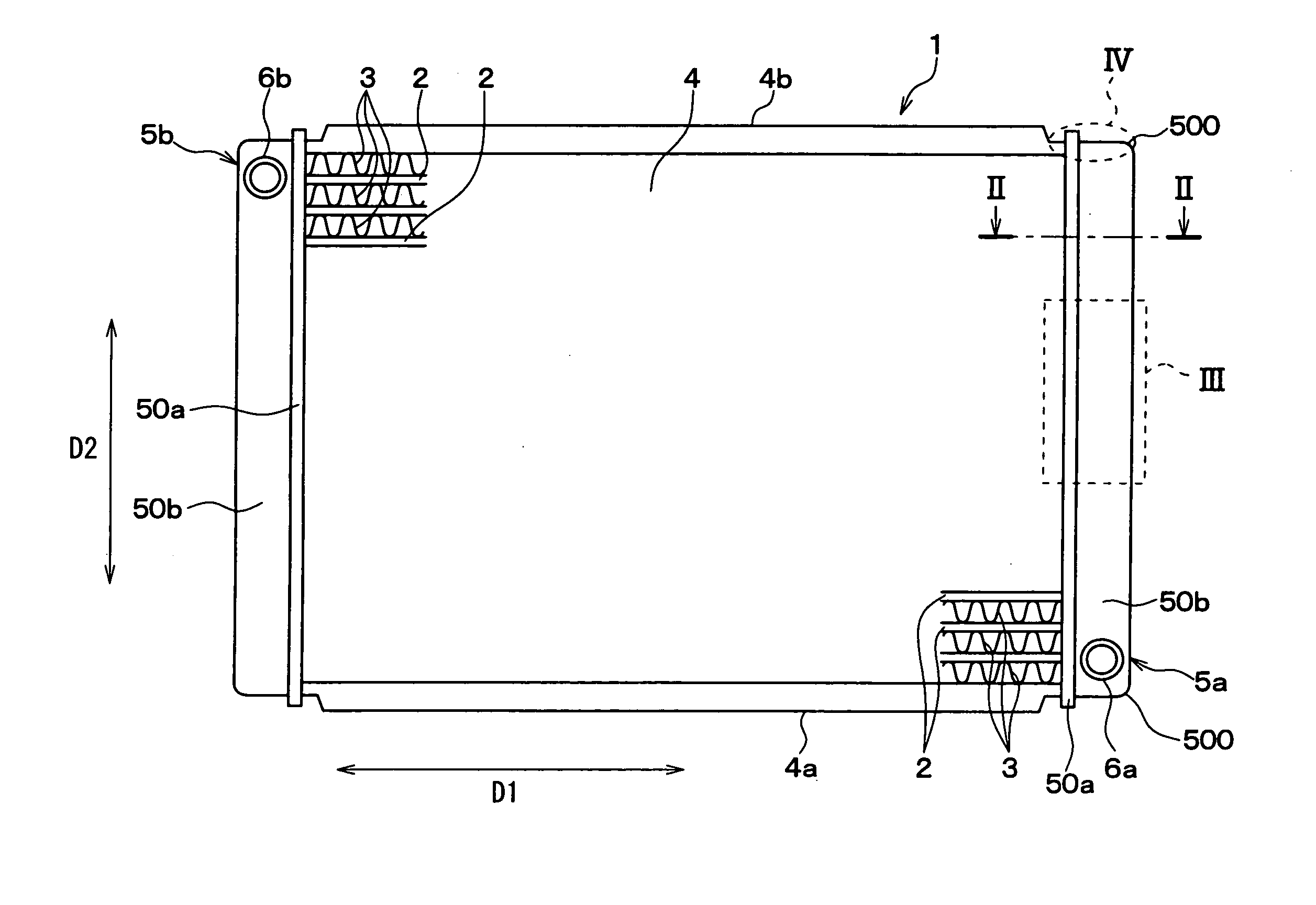

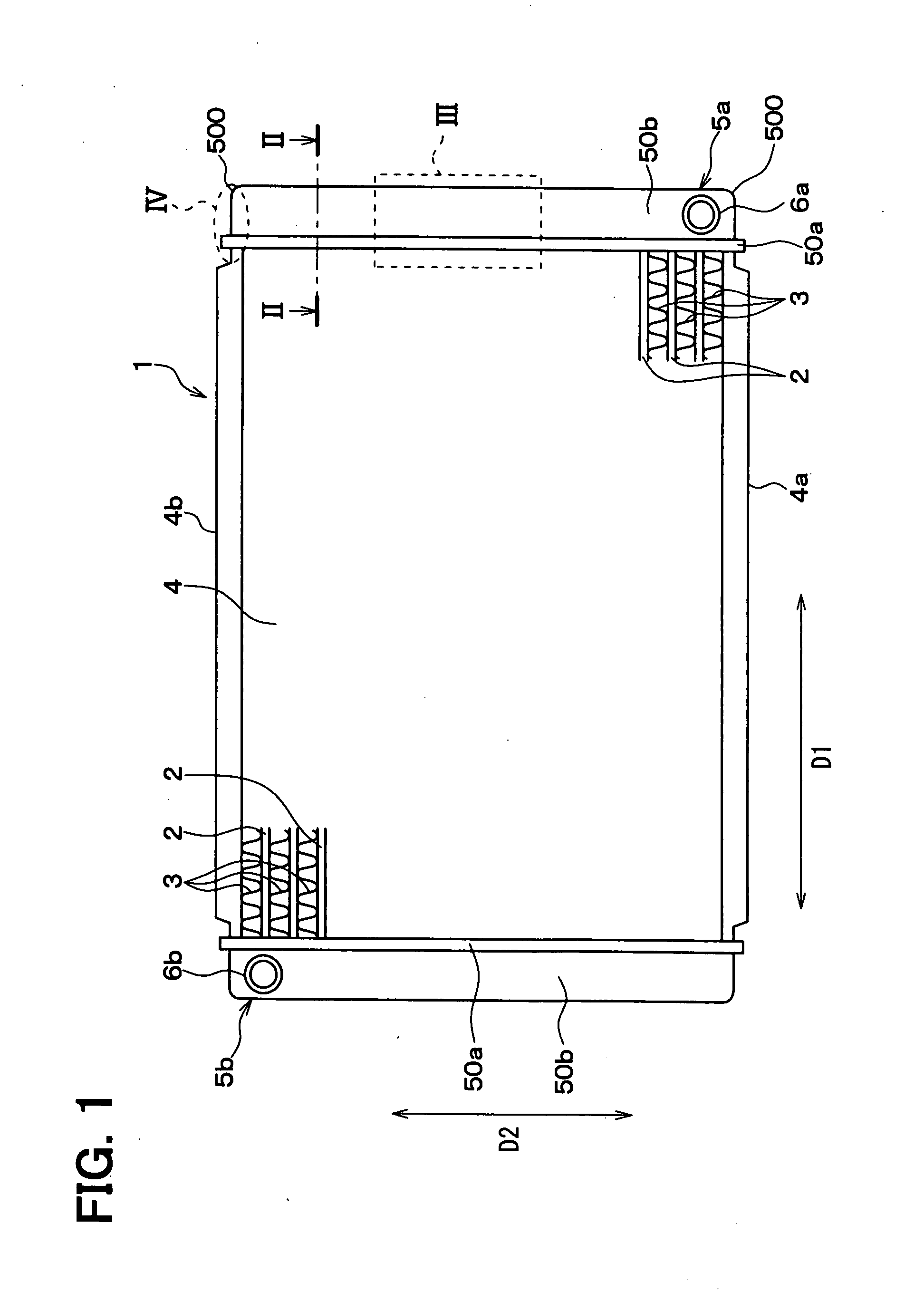

[0046]FIG. 1 shows a heat exchanger 1 of the first embodiment when viewed along a flow direction of air. The heat exchanger 1 is exemplarily employed to a radiator that is generally mounted in an engine compartment of a vehicle and performs heat exchange between an engine coolant and the air, the flow of which is for example generated by a blower, thereby to cool the engine coolant.

[0047]The radiator 1 generally includes tubes 2, fins 3, side plates 4a, 4b and header tanks 5a, 5b. The tubes 2 have generally flat tubular shapes, and form passages therein for allowing the engine coolant, which flows out from the engine, to pass through. The tubes 2 are, for example, made of light metals having high heat conductivity. In the present embodiment, the tubes 2 are exemplarily made of aluminum alloy. Also, the tubes 2 are formed of clad members, at least one of surfaces of which is coated with a filler material, such as a brazing material.

[0048]The fins 3 are joined to outer surfaces of the...

second embodiment

[0101]In the radiator 1 of the second embodiment, the core plate 50a has a shape slightly different from the core plate 50a of the radiator 1 of the first embodiment.

[0102]In a case that the tank body 50b and the core plate 50a are made of different materials, such as aluminum alloy and resin, the tank body 50b has a coefficient of linear expansion greater than that of the core plate 50a. Under a high temperature condition, the end wall portions 52c, 52d will be deformed by being pressed by the projected end 600 in the tank longitudinal direction D2 due to thermal expansion of the tank body 50b.

[0103]In the second embodiment, therefore, the core plate 50a includes support wall portions 610 for supporting the end wall portions 52c, 52d, as shown in FIGS. 12, 13A and 13B. The support wall portions 610 project from the lengthwise edges of the bottom wall portion 51, at positions adjacent to the longitudinal ends of the core plate 50a. In addition, the support wall portions 610 connect...

third embodiment

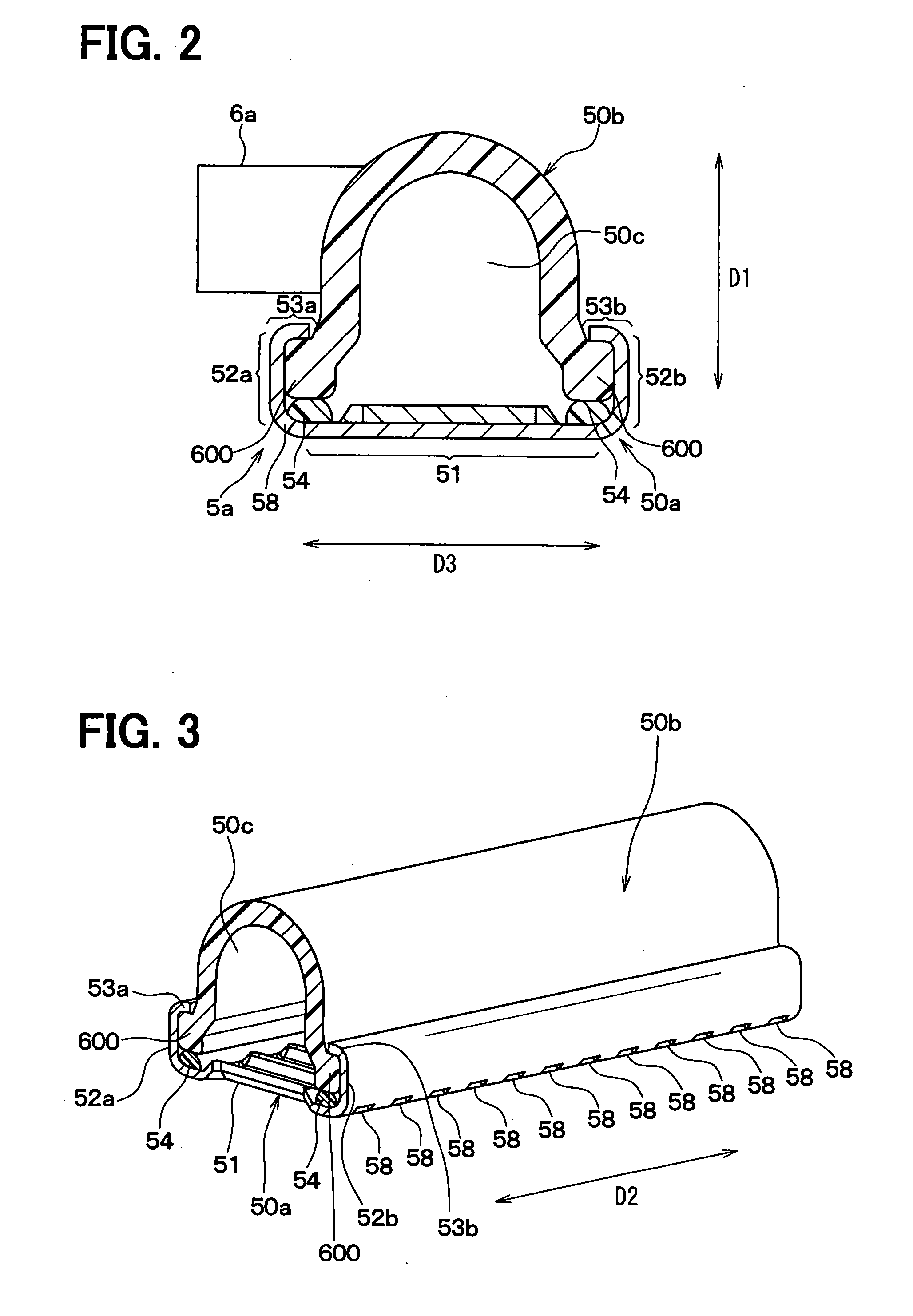

[0106]In the core plate 50a of the radiator 1 of the first embodiment, each of the side engagement portions 53a, 53b forms a generally right angle with the corresponding side wall portion 52a, 52b, as shown in FIG. 2. However, the angle between the side engagement portion 53a, 53b and the side wall portion 52a, 52b can be modified.

[0107]In the radiator 1 of the third embodiment, each side engagement portion 53a, 53b is engaged with the projected end 600 such that an angle +1 between the side engagement portion 53a, 53b and the side wall portion 52a, 52b is smaller than 90 degrees, as shown in FIG. 15. Therefore, an engagement force, that is, a force for joining the tank body 50b with the core plate 50a improves. Further, the sealing effect of the sealing member 54 improves.

[0108]The above engagement structure may be also employed to the end engagement portions 53c, 53d. That is, the end engagement portions 53c, 53d may be engaged with the projected end 600 such that the angle betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com