Three-dimensional zinc/carbon composite material for zinc-based battery and preparation method of three-dimensional zinc/carbon composite material

A carbon composite material, zinc-based battery technology, applied in battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of poor conductivity of zinc negative electrode, poor electrochemical performance, degradation of cycle life, etc., and achieve high conductivity High performance, high energy density, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A three-dimensional zinc / carbon composite electrode, which is prepared through the following steps:

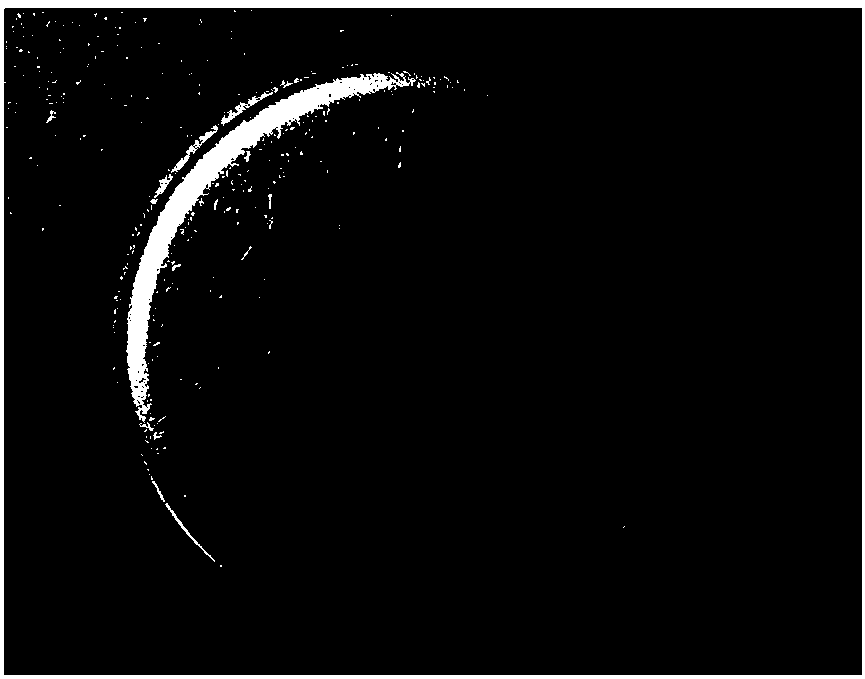

[0037] (1) Mix 400g of zinc oxide and 100g of polyacrylonitrile (the mass ratio of the two is 4:1), disperse into 50g of N,N dimethylformamide, and then stir in a beaker at room temperature for about 24 hours ; figure 2 A mesh map that has been extruded 3D printed.

[0038] (2) put into the circular mold through the system of step (1), carry out setting under 20 MPa;

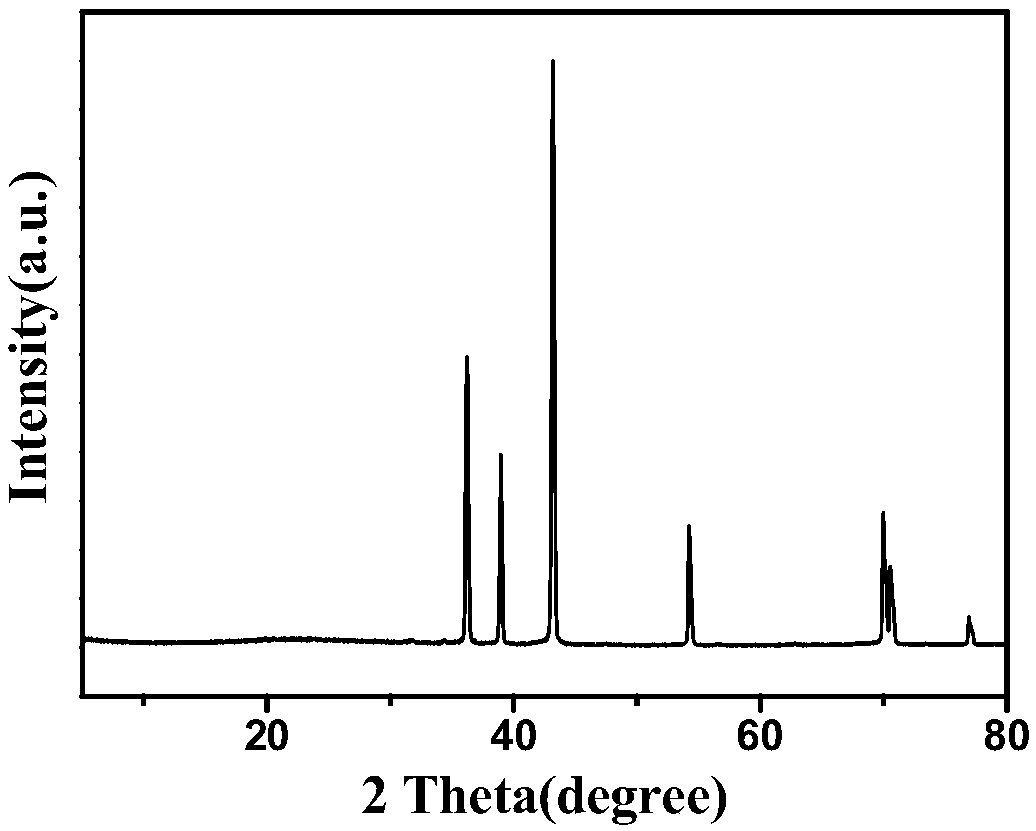

[0039] (3) Carry out high-temperature carbonization at 550°C, then carry out compression molding treatment on the obtained product and then perform electrochemical reduction: use an electrochemical workstation, use a three-electrode system, and use a voltage- 50mV for electrochemical reduction, and the product is a three-dimensional zinc (zinc oxide) / carbon composite electrode.

[0040] In the technical solution of the present invention, carbon and zinc oxide are obtained after heat treatment, and all...

Embodiment 2

[0051] This embodiment provides a three-dimensional zinc metal electrode, the preparation method of which is basically the same as that of embodiment 1, except that the mass ratio of zinc oxide and polyacrylonitrile is 10:1. The three-dimensional zinc metal electrode is made into a working electrode according to the method provided by the present invention and the corresponding electrical performance test is carried out. The results are as follows: when charging and discharging at 1C, the stable specific capacity is 480mAh / g; when charging and discharging at the above rate, 500mAh / g After repeated charging and discharging, the capacity can maintain more than 70% of the initial capacity.

Embodiment 3

[0053] This example provides a three-dimensional zinc metal electrode, the preparation method of which is basically the same as that of Example 1, the difference is that the mass ratio of zinc oxide to polyacrylonitrile is 0.5:1.

[0054] The three-dimensional zinc metal electrode is made into a working electrode according to the method provided by the present invention and the corresponding electrical performance test is carried out. The results are as follows: when charging and discharging at 1C, the stable specific capacity is 400mAh / g; when charging and discharging at the above rate, 500mAh / g After repeated charging and discharging, the capacity can maintain more than 60% of the initial capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com