Metal alloy composites

A technology of metal composite materials and composite materials, which is applied in the field of metal composite materials and metal alloy composite materials, and can solve problems such as accelerated stress corrosion and plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0114] The production of metal composites involves significantly higher processing temperatures. Furthermore, molten metals are known to be highly reactive towards sulfur and its compounds at high temperatures. This fact is expected to impair the performance of metal matrix composites containing nanostructures.

[0115] In one embodiment, the present invention provides the use of WS 2 Nanotube-reinforced first bulk metal composite. The strengthening mechanism of these composites is discussed. For comparison, multi-walled carbon nanotube (CNT)-Mg alloy MMCs were also prepared in this series of experiments. Apparently, they did not produce any potentiating effect in this case (see Table 1).

[0116] The novel INT-WS based 2 The Mg composites were prepared by melt stirring without further mechanical or chemical processing. Compared with pure Mg alloys, these novel INT-WS based 2 Mg composites show stronger and tougher properties. This property does not appear in conventio...

Embodiment 1

[0304] Material

[0305] The Mg alloy used in this example was commercially available AZ31 (Taiwan Mach Technology (LINYI) Co.) with ~3.0 at% aluminum. Table 11 lists the chemical composition of the alloys listed by the manufacturer.

[0306] Table 11. Chemical composition (in wt%) of AZ31 alloy (Mg about 94.5 wt%)

[0307]

[0308] WS 2 Nanotubes are produced by using a fluidized bed reactor (i.e. a vertical reactor in which the reaction gas, i.e. H 2 S and H 2 In addition, the reactive powder is fluidized (floated) by a flow of gas such as nitrogen) to make the slightly reduced WO 3 Nanoparticles and H 2 S is made by reacting at a temperature between 850°C and 900°C.

Embodiment 2

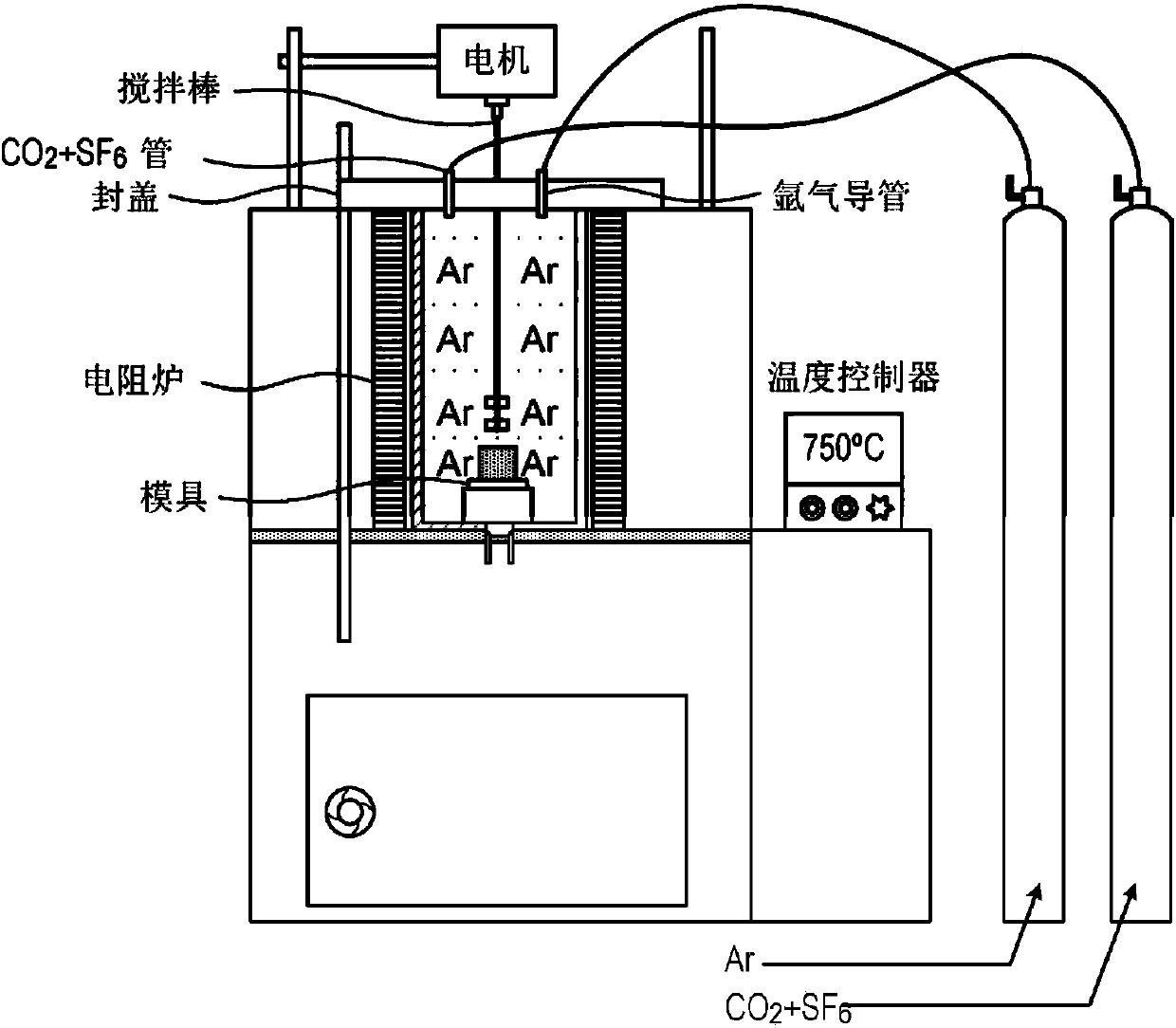

[0310] Preparation of Mg MMC Containing Inorganic Nanotubes

[0311] The AZ31 and WS 2 The nanotubes were placed in a graphite crucible and heated to 400 °C for 15 min in a resistance heating furnace; then a stirring blade was applied; at the same time, the CO 2 and SF 6 Gas is bubbled into the crucible to help mix the melt. CO 2 and SF 6 The gas also helps prevent residual water and air from oxidizing the melt. Afterwards, the melt was heated up to 600° C. for 15 minutes. The crucible was further gradually heated to 700°C-720°C and the molten alloy was stirred for 3 minutes with a blade running at 350 rev / min. Finally, the composite melt is poured into metal molds. At this point further mechanical testing was prepared for Mg MMC containing nanotubes in a weight fraction of 0.1 wt% - 1 wt% (see Table 12). Each composition was replicated at least three times. Initially, the nanotubes were mixed in the metal melt using paddle agitation ("a" in Table 12). However, due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com