Device for preparing reclaimed sand through waste concrete

A technology for waste concrete and recycled sand, which is applied in the direction of grain processing, etc., can solve the problems of incapable of waste concrete crushing, low energy consumption and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

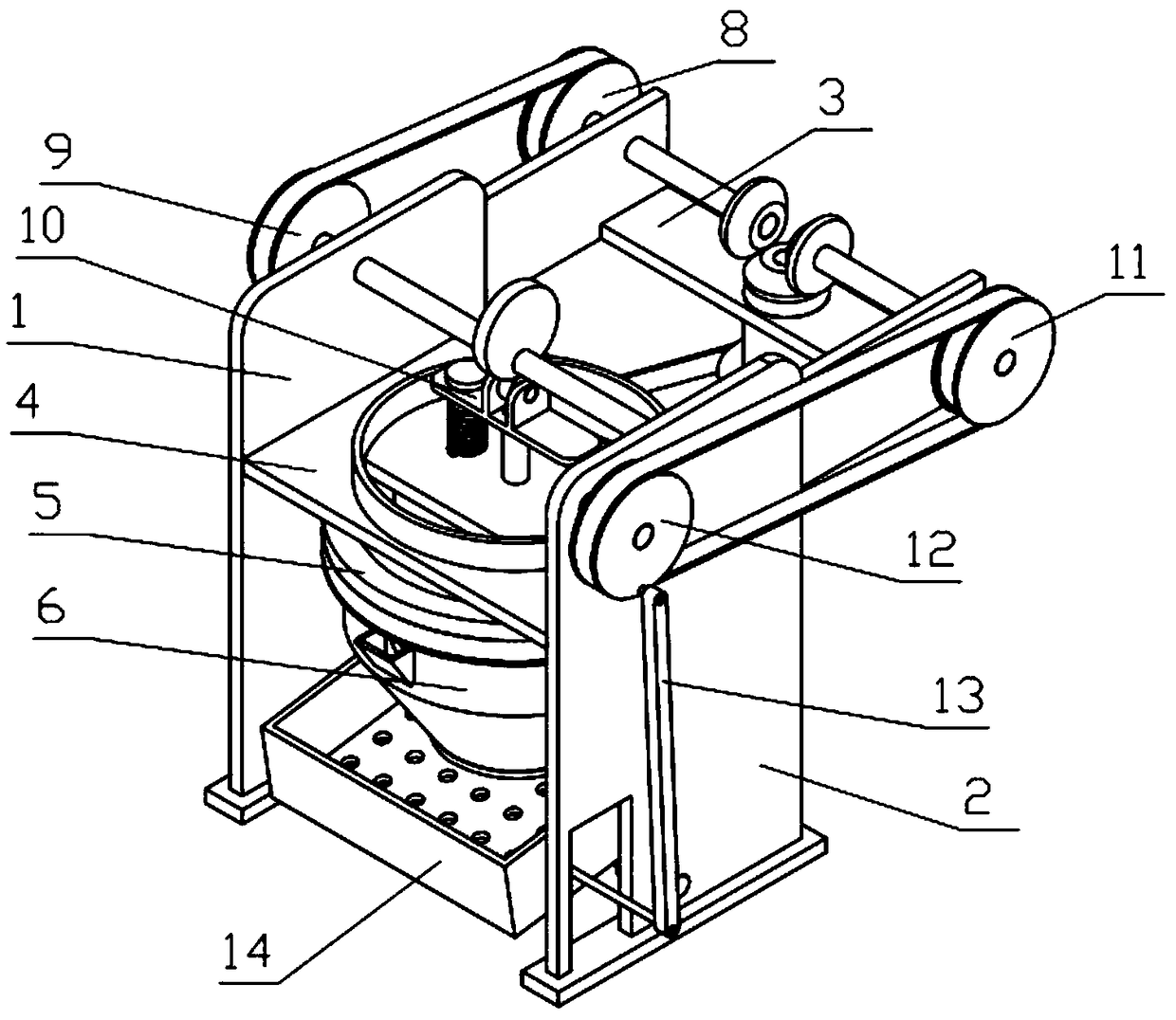

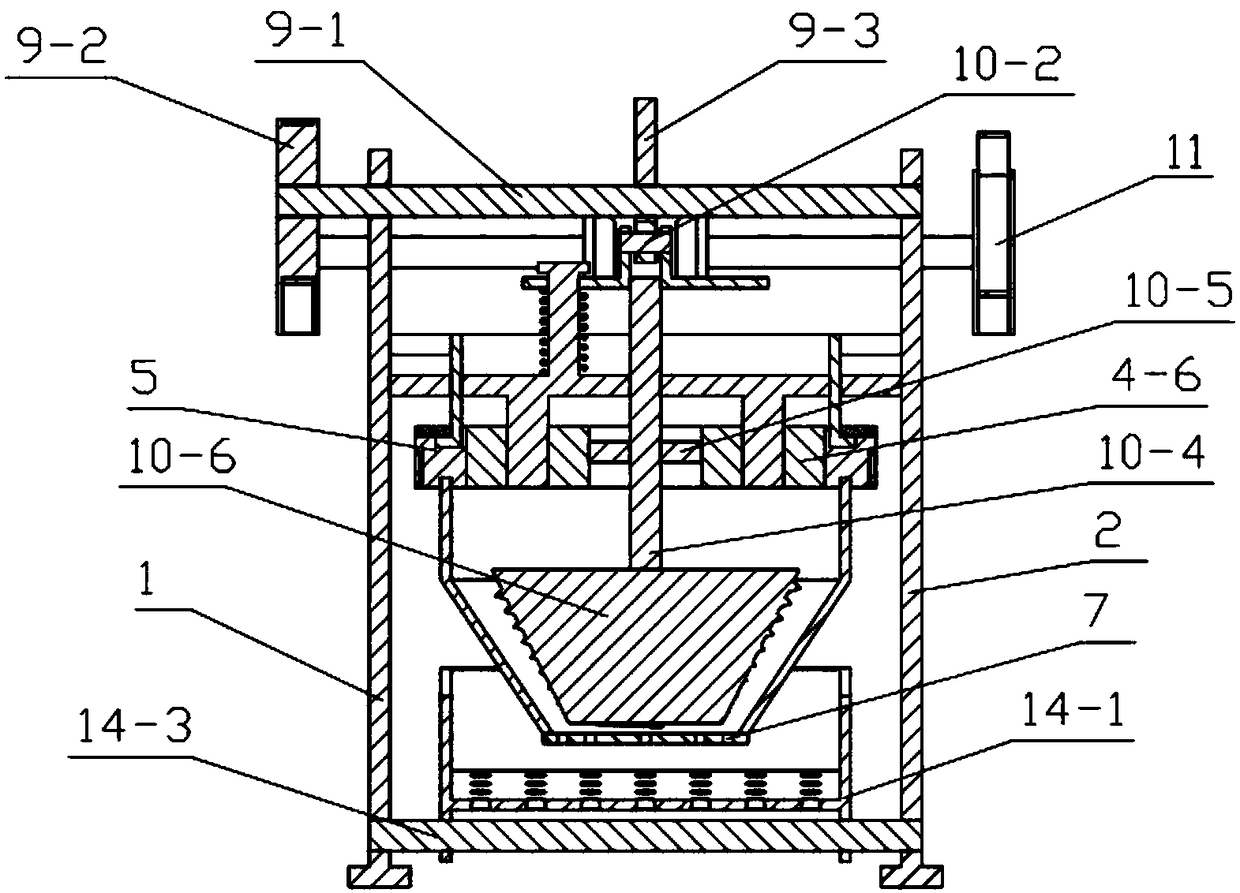

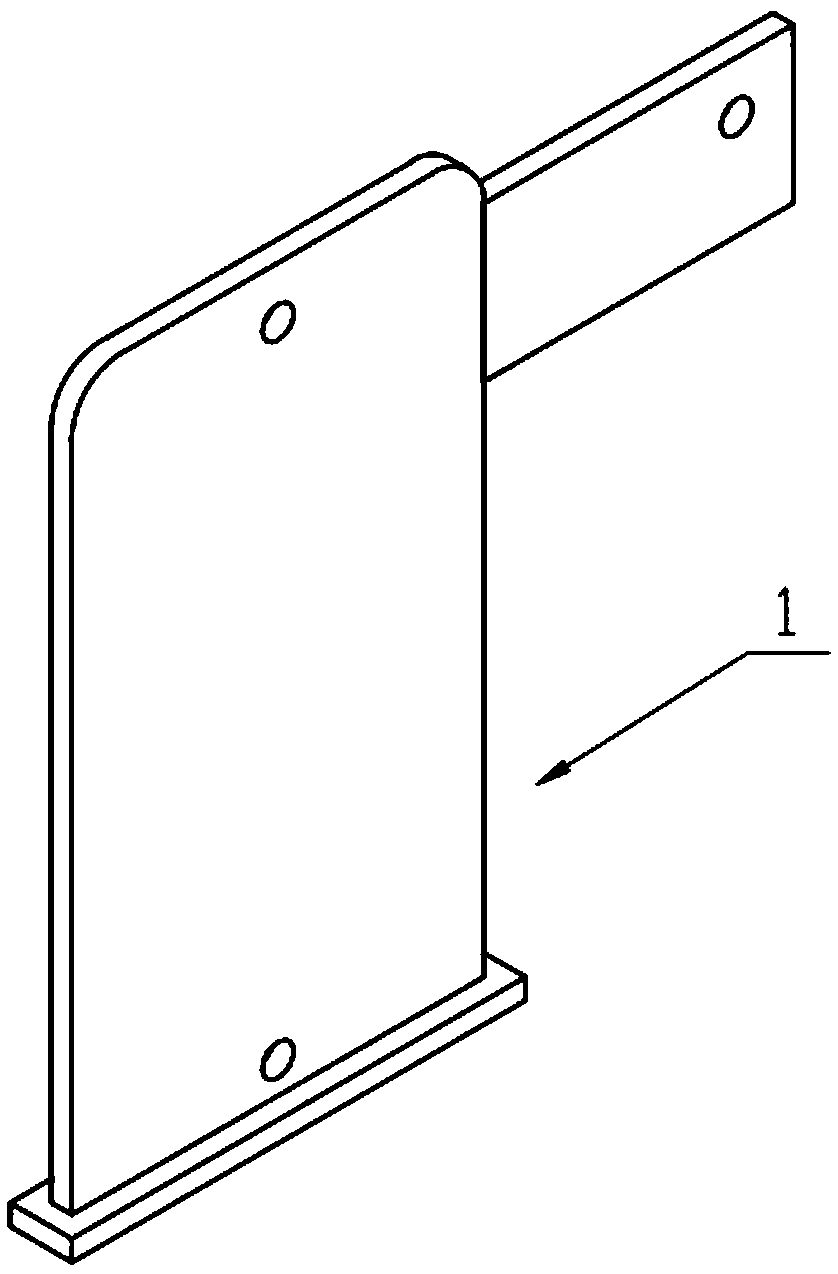

[0040] Combine below Figure 1-18Describe this embodiment, a device for preparing recycled sand from waste concrete, including side support I1, side support II2, power mechanism 3, planetary gear mechanism 4, ring gear 5, crushing cylinder 6, screening plate 7, transmission mechanism I8, The pushing mechanism 9, the crushing mechanism 10, the transmission mechanism II 11, the crank mechanism 12, the connecting rod 13 and the screening box 14 can carry out two-way crushing of the concrete through the crushing cylinder 6 and the crushing mechanism 10 to completely break the concrete, and pass through the screening box 14 to crush the concrete. Thoroughly broken concrete is screened.

[0041] Described planetary gear mechanism 4 comprises supporting plate 4-1, supporting tube 4-2, planetary wheel bottom plate 4-3, sliding column 4-4, rotating column 4-5 and planetary wheel 4-6, and supporting tube 4-2 is fixed Connected to the support plate 4-1, the planetary wheel base plate 4-...

specific Embodiment approach 2

[0044] Combine below Figure 1-18 This embodiment will be described. This embodiment will further describe the first embodiment. The side bracket II2 is provided with a rectangular groove 2-1.

specific Embodiment approach 3

[0045] Combine below Figure 1-18 Illustrate this embodiment, and this embodiment will further illustrate Embodiment 2. The power mechanism 3 includes a power bracket 3-1, a motor 3-2, a power bevel gear 3-3 and a power pulley 3-4, and the motor 3- 2 Fixedly connected to the power bracket 3-1, the power bevel gear 3-3 and the power pulley 3-4 are respectively fixedly connected to the upper and lower ends of the output shaft of the motor 3-2, and the power bracket 3-1 is fixedly connected to the side bracket I1 Between the side bracket II2; when in use, the construction waste is poured into the crushing cylinder 6-1 through the material inlet provided on the crushing cylinder 6-1, the motor 3-2 is started, and the output shaft of the motor 3-2 starts Rotate, the output shaft of motor 3-2 drives power bevel gear 3-3 and power pulley 3-4 to rotate simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com