Preparation and purification method of fructo-oligosaccharide

A technology of fructooligosaccharides and purification methods, which is applied in the field of natural substance extraction, can solve the problems of complex operation, low removal efficiency of bitter element and bitter peptide, etc., and achieve the effect of simple operation, less impurities and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

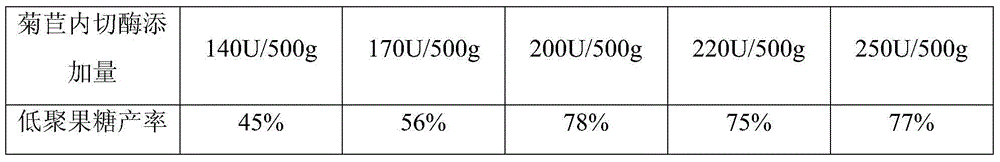

[0032] Embodiment 1: The effect of the optimum addition amount of endo-inuclease on the yield of fructo-oligosaccharides.

[0033] Take 500g of fresh chicory as raw material, wash and peel it, then crush it with a blender, add 1L of pure water, stir well, adjust pH=5.8, add 100U pectinase, treat at 30°C for 5h, then boil 15min. Add 140U, 170U, 200U, 220U, 250U endoinulinase to each group of systems, treat at 30°C for 24h, and then filter to remove chicory residue to obtain fructo-oligosaccharide mixture. Detect the content of fructo-oligosaccharide in the fructo-oligosaccharide mixed solution that each experimental group obtains, test result is shown in Table 1, as can be seen from Table 1, adding endo-inuclease in every 500g chicory system can degrade the inulin in chicory , Increase the content of fructooligosaccharides.

[0034] The influence of table 1 endo-inuclease optimal addition amount on fructo-oligosaccharide yield

[0035]

Embodiment 2

[0036] Example 2: Effect of endo-inuclease action time on the yield of fructo-oligosaccharides.

[0037] Take 500g of fresh chicory as raw material, wash and peel it, then crush it with a blender, add 1L of pure water, stir evenly, adjust pH=5.8, add 200U pectinase, treat at 30°C for 5h, then boil 15min. Add 200U endoinulinase to each group of systems, treat at 30°C for 6h, 12h, 18h, 24h, 30h, 36h, 42h, 48h, and then filter to remove chicory residue to obtain a fructooligosaccharide mixture. Detect the content of fructo-oligosaccharide in the fructo-oligosaccharide mixture obtained by each experimental group, and the test results are shown in Table 2. It can be seen from the table that the yield of fructo-oligosaccharide obtained by treating chicory with endo-inuclease for 24h-36h is higher, and the treatment time is shorter, which is suitable for industrial application.

[0038] The impact of table 2 endoinulinase action time on fructooligosaccharides productive rate

[00...

Embodiment 3

[0040] Example 3: Effect of endoinuclease action temperature on the yield of fructooligosaccharides.

[0041] Take 500g of fresh chicory as raw material, wash and peel it, then crush it with a blender, add 1L of pure water, stir evenly, adjust pH=5.8, add 300U pectinase, treat at 30°C for 5h, then boil 15min. Add 200 U of endo-inulinase to each group of systems, treat at 25°C, 30°C, 35°C, 40°C, and 45°C for 36 hours, and then filter to remove chicory residue to obtain a fructooligosaccharide mixture. Detect the content of fructo-oligosaccharide in the fructo-oligosaccharide mixture obtained by each experimental group, and the test results are shown in Table 3. As can be seen from Table 3, the yield of fructo-oligosaccharides is higher at 30-35°C.

[0042] The influence of table 3 endo-inuclease action temperature on fructo-oligosaccharide yield

[0043] time 25℃ 30℃ 35℃ 40℃ 45℃ FOS yield 65% 72% 77% 65% 59%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com