Secondary breaker for whole waste tire

A waste tire, secondary crushing technology, applied in the direction of grain processing, etc., can solve the problems of unreasonable tool structure, increased production cost, easy jamming of primary crusher, etc., to achieve stable and uniform crushing action and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

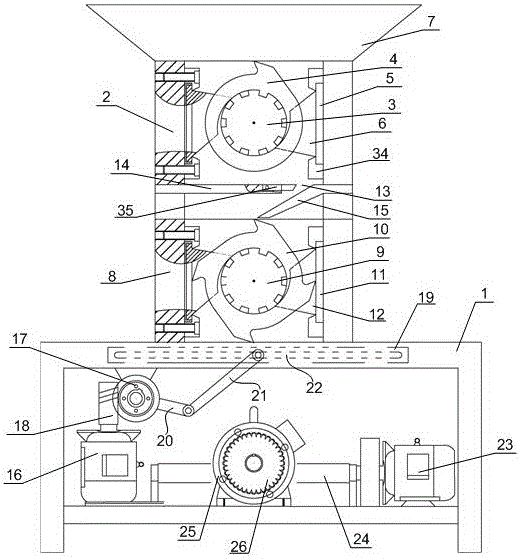

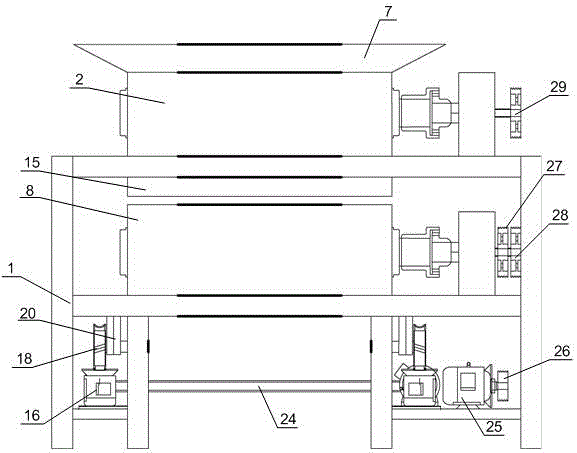

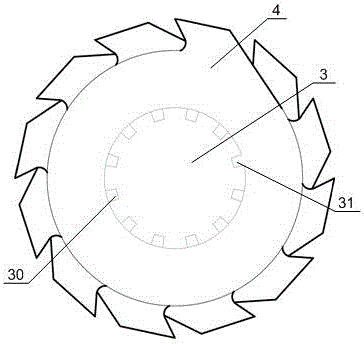

[0031] see Figure 1~Figure 9 As shown, the present invention provides a secondary shredder for whole tires of waste tires, which includes a frame 1 and a primary crushing chamber and a secondary crushing chamber installed on the frame 1; wherein, the primary crushing chamber includes upper and lower two The first box body 2 is hollow and open at the end, and the first moving knife assembly and the first static knife assembly installed on both sides of the first moving knife assembly are installed in the first box body 2 . Wherein, the first moving knife assembly includes a first moving knife shaft 3 and a plurality of first moving blades 4 installed on the first moving knife shaft 3 , and the first static knife assembly includes The first static knife positioning plate 5 on the wall, a plurality of first static blades 6 are installed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com