Recycled plastic preliminary crushing equipment

A technology for primary crushing and recycling of plastics, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of incomplete crushing of plastics and inconvenient collection of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

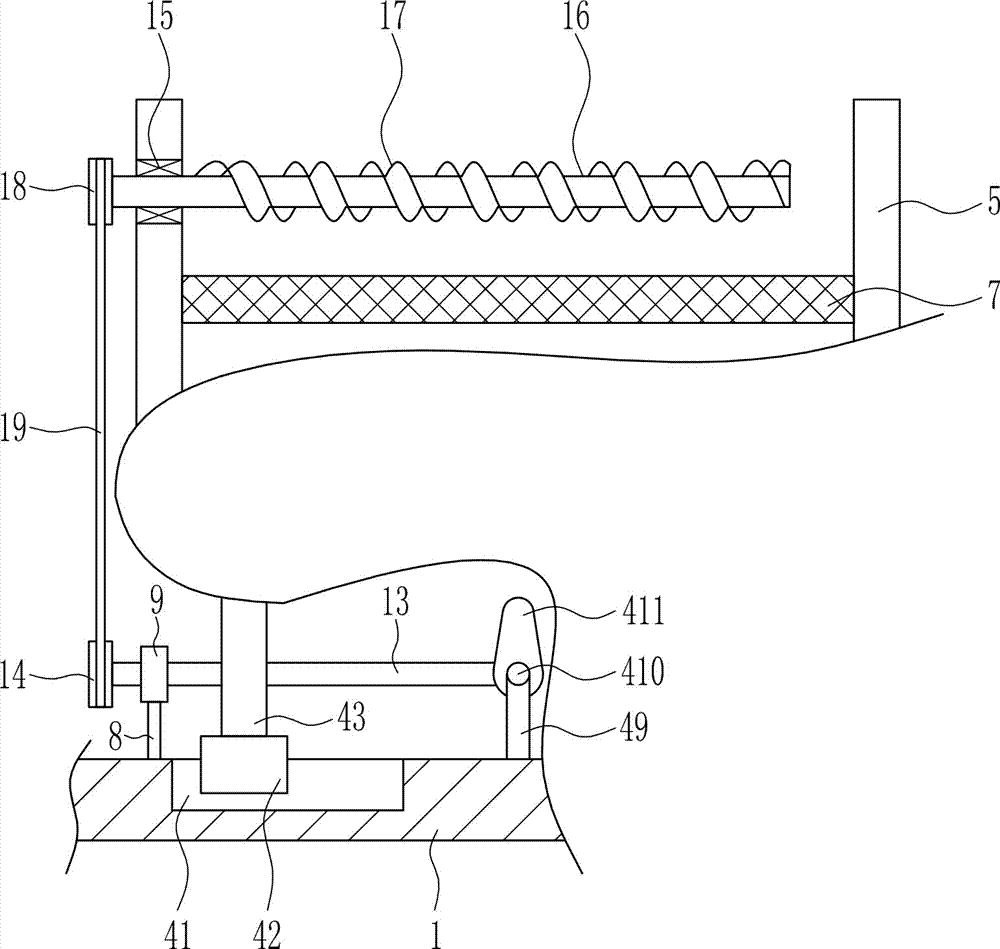

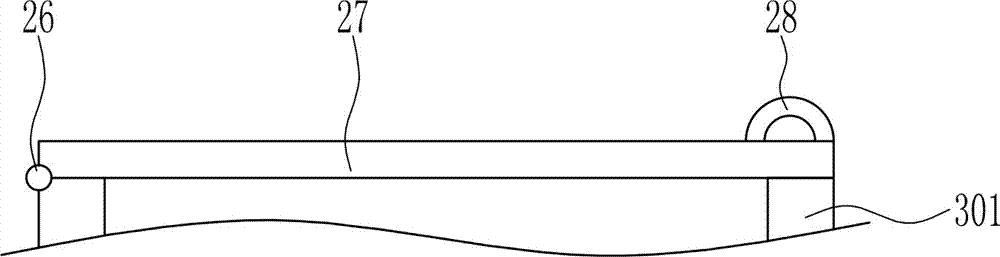

[0036] A primary crushing equipment for recycled plastics, such as Figure 1-8 As shown, it includes a base plate 1, an L-shaped strut 2, a crushing device 3, a shaking device 4, a screening frame 5, and a screen 7. The left side of the base plate 1 is provided with an L-shaped strut 2, and the right side of the L-shaped strut 2 A crushing device 3 is arranged on the upper part, a shaking device 4 is arranged in the middle of the bottom plate 1, a screening frame 5 is arranged on the top of the shaking device 4, a discharge port 6 is opened on the lower part of the right wall of the screening frame 5, and a mesh plate 7 is arranged inside the screening frame 5.

Embodiment 2

[0038] A primary crushing equipment for recycled plastics, such as Figure 1-8 As shown, it includes a base plate 1, an L-shaped strut 2, a crushing device 3, a shaking device 4, a screening frame 5, and a screen 7. The left side of the base plate 1 is provided with an L-shaped strut 2, and the right side of the L-shaped strut 2 A crushing device 3 is arranged on the upper part, a shaking device 4 is arranged in the middle of the bottom plate 1, a screening frame 5 is arranged on the top of the shaking device 4, a discharge port 6 is opened on the lower part of the right wall of the screening frame 5, and a mesh plate 7 is arranged inside the screening frame 5.

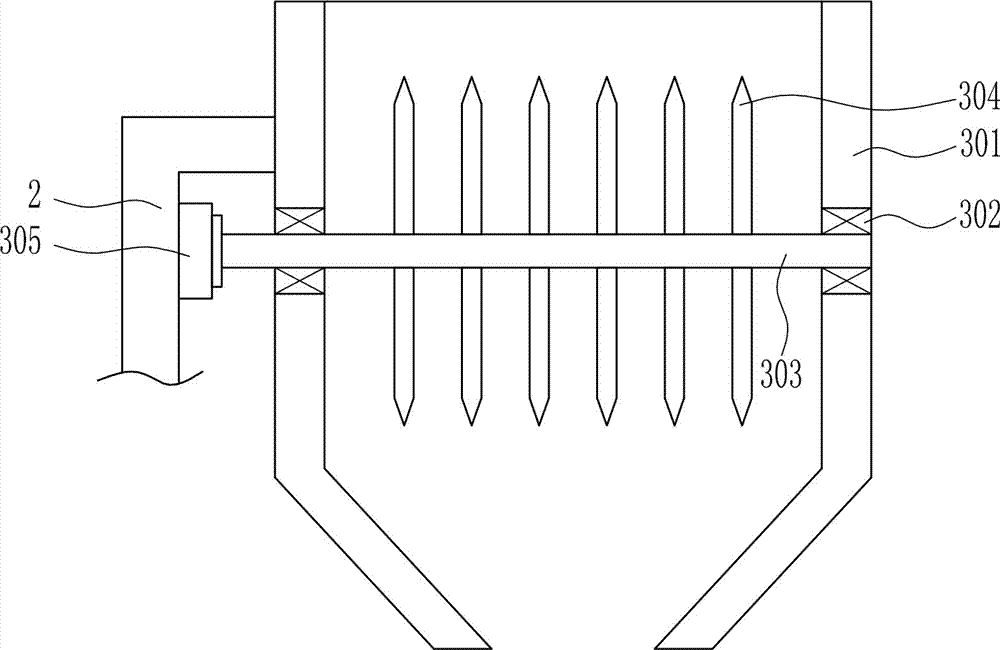

[0039] The crushing device 3 includes a crushing frame 301, a first bearing 302, a first rotating shaft 303, a cutter 304 and a first motor 305. The upper end of the right side of the L-shaped pole 2 is provided with a crushing frame 301, and the left and right walls of the crushing frame 301 are symmetrical in the mid...

Embodiment 3

[0041] A primary crushing equipment for recycled plastics, such as Figure 1-8 As shown, it includes a base plate 1, an L-shaped strut 2, a crushing device 3, a shaking device 4, a screening frame 5, and a screen 7. The left side of the base plate 1 is provided with an L-shaped strut 2, and the right side of the L-shaped strut 2 A crushing device 3 is arranged on the upper part, a shaking device 4 is arranged in the middle of the bottom plate 1, a screening frame 5 is arranged on the top of the shaking device 4, a discharge port 6 is opened on the lower part of the right wall of the screening frame 5, and a mesh plate 7 is arranged inside the screening frame 5.

[0042] The crushing device 3 includes a crushing frame 301, a first bearing 302, a first rotating shaft 303, a cutter 304 and a first motor 305. The upper end of the right side of the L-shaped pole 2 is provided with a crushing frame 301, and the left and right walls of the crushing frame 301 are symmetrical in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com