Rotary vertical garbage incinerator

A waste incinerator, vertical technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of high maintenance cost, complicated manufacturing and installation process, etc., and achieve low maintenance cost, complete combustion, and installation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

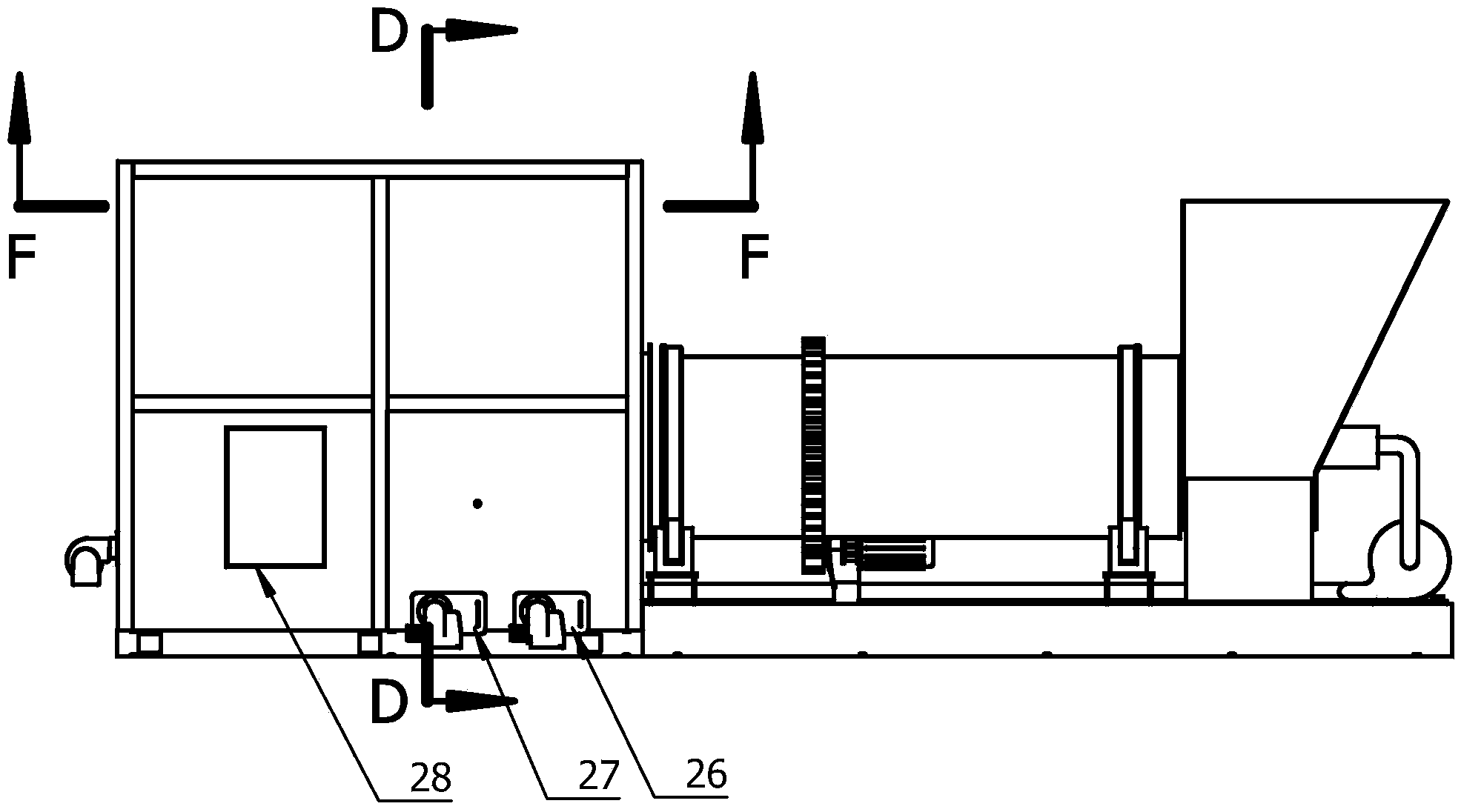

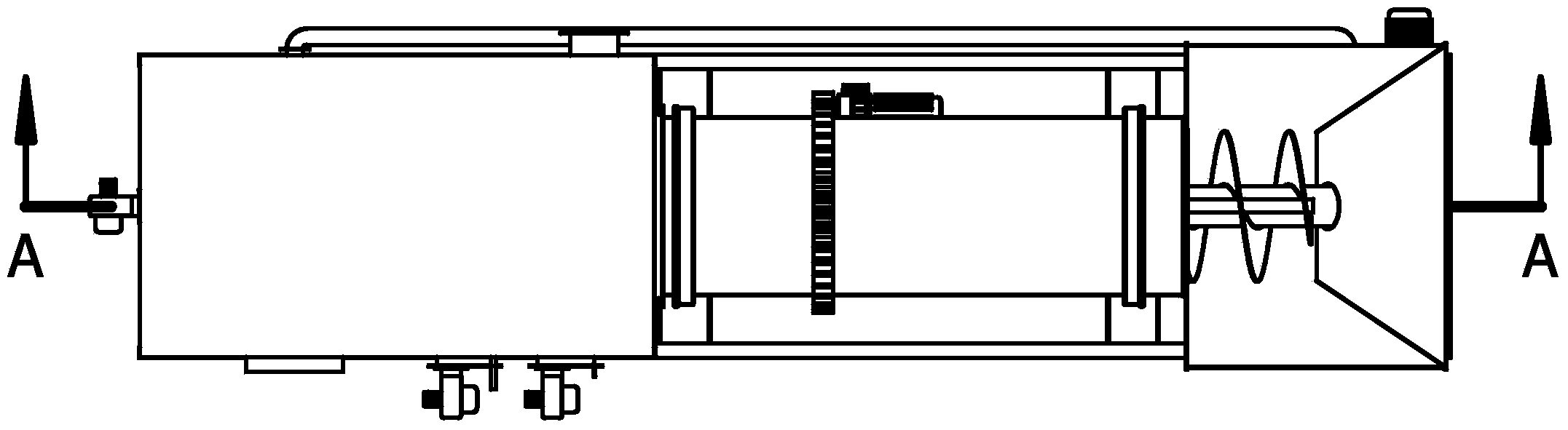

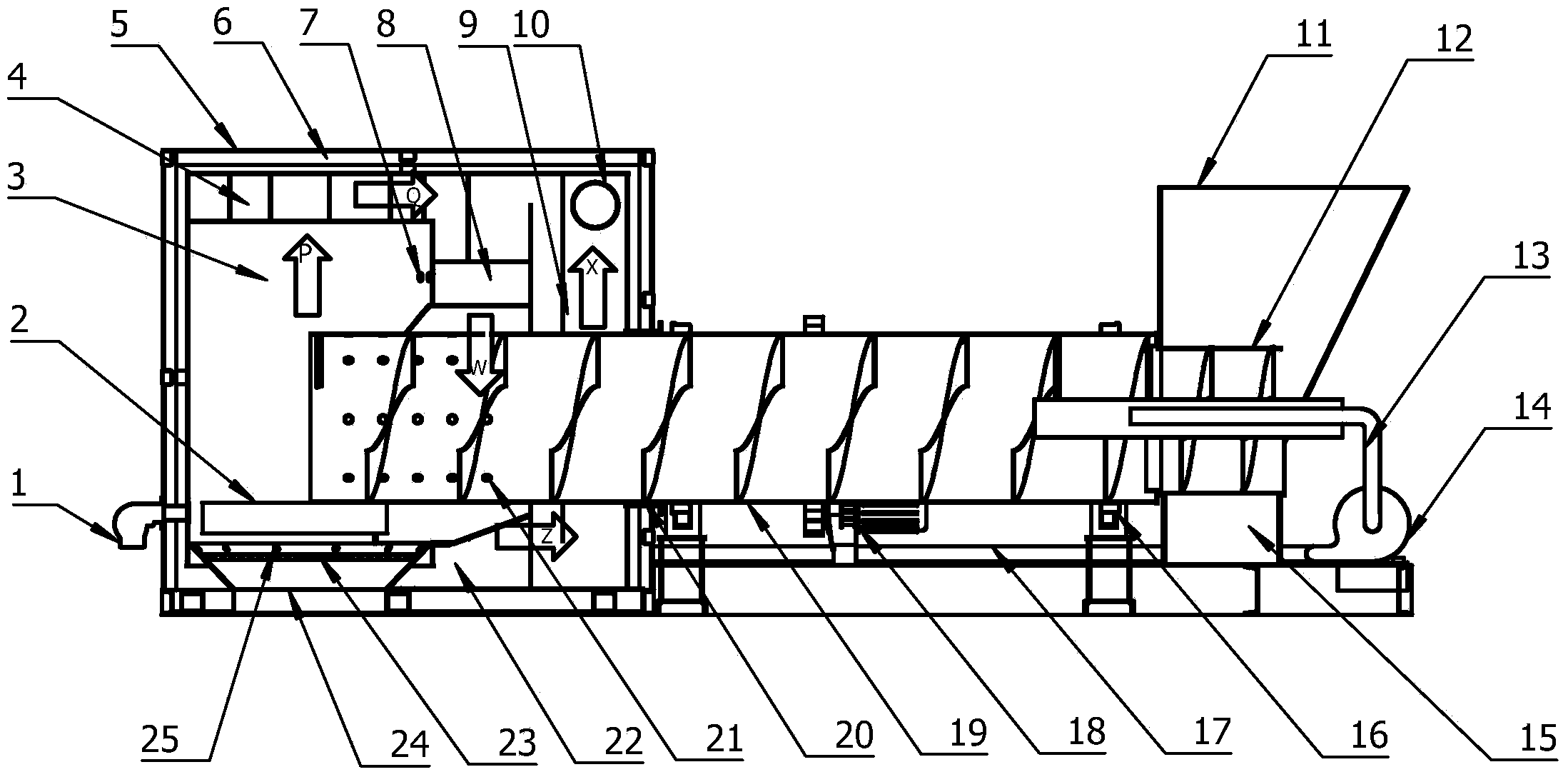

[0038] Figure 1 to Figure 5 Disclosed in is a rotary vertical garbage incinerator, including a casing 5, a combustion chamber located in the casing, and a feeding device. The combustion chamber includes a primary combustion chamber 3, an annular flue gas pyrolysis chamber 4, a secondary The combustion chamber 22 and the third-stage combustion chamber 9 are filled with vermiculite refractory material 6 between the shell 5 and the first-stage combustion chamber 3, the annular flue gas pyrolysis chamber 4, the second-stage combustion chamber 22, and the third-stage combustion chamber 9; The primary combustion chamber 3 can be cylindrical or square; the annular flue gas pyrolysis chamber 4 is a two-ring structure, and the smoke inlet of the annular flue gas pyrolysis chamber 4 communicates with the primary combustion chamber 3. The smoke outlet of the gas pyrolysis chamber 4 communicates with the secondary combustion chamber 22, and the secondary combustion chamber 22 communicates...

Embodiment 2

[0048] Figure 6 ~ Figure 7 Disclosed in is another kind of rotary vertical garbage incinerator, this incinerator is for incinerating garbage with low water content or flammable, its basic structure is the same as that of embodiment 1, the difference is that: the rotary drying and feeding The other end of the drum 19 directly extends into the inside of the primary combustion chamber 3, which can reduce the cost of manufacture and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com