Comprehensive extraction process for auricularia auricula polysaccharide

A technology for comprehensive extraction of polysaccharides from fungus, which is applied in the field of comprehensive extraction technology of polysaccharides from fungus, can solve the problems of destroying the active structure of polysaccharides, harsh conditions for use, and difficult desalination processes, and achieve high dissolution rate of polysaccharides, mild reaction conditions, and improved Effect of Dissolution Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Comprehensive extraction of embodiment 1 fungus polysaccharide

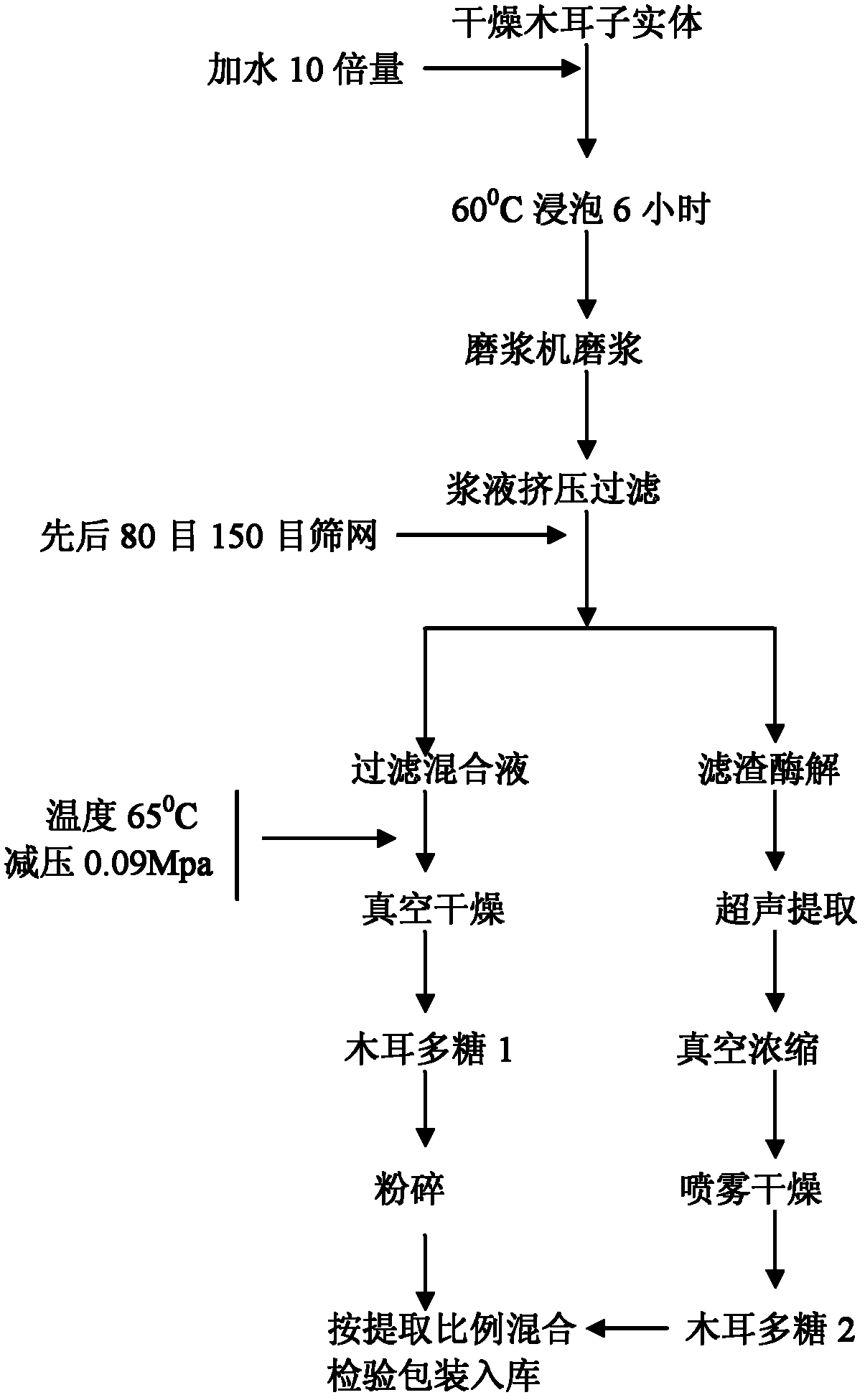

[0046] The extraction process of fungus polysaccharides is as follows: figure 1 shown.

[0047] The comprehensive extraction method of fungus polysaccharide is:

[0048] 1. Dry the fruiting body of the fungus, pick out the impurities, weigh the feeding amount, wash with water to remove the sediment, then add 10 times the amount of water, heat to 60 degrees and soak for 6 hours. Turn to the refining post.

[0049] 2. Use a refiner to refine the soaked and fully expanded fungus with water to make a uniform slurry. Switch to filter position.

[0050] 3. First install the press filter with 80-mesh steel mesh, squeeze and filter, and then change to 150-mesh steel mesh for extrusion and filtration, separate the filter residue and filtrate, the filtrate is concentrated under reduced pressure, and the filter residue is transferred to the extraction post.

[0051] 3.1 Concentrate the filtrate under reduced pre...

Embodiment 2

[0067] Comprehensive extraction of embodiment 2 fungus polysaccharide

[0068] The comprehensive extraction method of fungus polysaccharide is:

[0069] 1. Dry the fruiting body of the fungus, pick out the impurities, weigh the feeding amount, wash with water to remove the sediment, then add 20 times the amount of water, heat to 50 degrees and soak for 8 hours. Turn to the refining post.

[0070] 2. Use a refiner to refine the soaked and fully expanded fungus with water to make a uniform slurry. Switch to filter position.

[0071] 3. First install the press filter with 80-mesh steel mesh, squeeze and filter, and then change to 150-mesh steel mesh for extrusion and filtration, separate the filter residue and filtrate, the filtrate is concentrated under reduced pressure, and the filter residue is transferred to the extraction post.

[0072] 3.1 Concentrate the filtrate under reduced pressure:

[0073] Turn on the vacuum pump and the circulating water cooling pump. When the v...

Embodiment 3

[0085] Comprehensive extraction of embodiment 3 fungus polysaccharide

[0086] The comprehensive extraction method of fungus polysaccharide is:

[0087] 1. Dry the fruiting body of the fungus, pick out the impurities, weigh the amount of material, wash with water to remove the sediment, then add 20 times the amount of water, heat to 70 degrees and soak for 5 hours. Turn to the refining post.

[0088] 2. Use a refiner to refine the soaked and fully expanded fungus with water to make a uniform slurry. Switch to filter position.

[0089] 3. First install the press filter with 80-mesh steel mesh, squeeze and filter, and then change to 150-mesh steel mesh for extrusion and filtration, separate the filter residue and filtrate, the filtrate is concentrated under reduced pressure, and the filter residue is transferred to the extraction post.

[0090] 3.1 Concentrate the filtrate under reduced pressure:

[0091] Turn on the vacuum pump and the circulating water cooling pump. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com