Lithium ion battery anode sheet

A lithium-ion battery and anode sheet technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of harsh synthesis conditions of anode materials, poor battery performance at low or high temperature, and unfavorable formation, and achieve reversible The effect of capacity and efficiency improvement, stable and dense structure, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

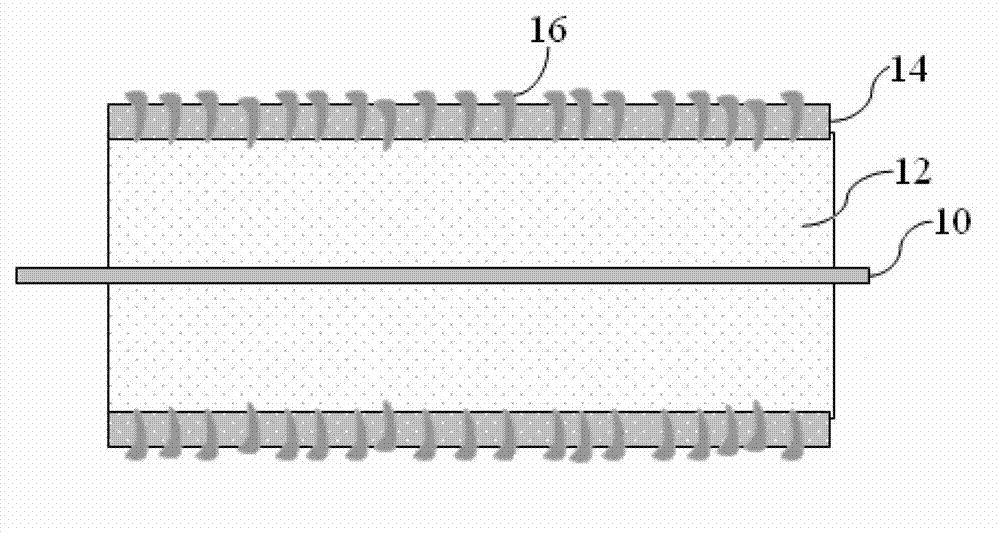

[0025] Embodiment 1: use silicon oxide alloy (Si a o b m c , a=c=0, b=0.95) as the anode active material, the anode active material, sodium carboxymethyl cellulose (CMC)-styrene-butadiene rubber (SBR) as the binder and dispersant, conductive carbon as the conductive agent , in weight percent, according to SiO 0.95 : CMC: SBR = 90: 5: 5 ratio mixing, high-speed stirring to obtain a uniformly dispersed slurry, and then evenly coated on the copper foil, blown to dry, and rolled to obtain a coating with an active material layer Anode sheet; similarly, Al 2 o 3 Particles, adhesive water-based siloxane and water are stirred at a high speed to obtain a uniformly dispersed slurry, and then the slurry is coated on the surface of the active material layer and dried to obtain a high-resistance layer with a thickness of 4 μm; finally, in A layer of lithium metal particles with a median particle size of 20 μm is evenly sprinkled on the high resistance layer, and the resistance per uni...

Embodiment 2

[0026] Example 2: The anode active material is graphite, and the high resistance material used in the high resistance layer is 0.05 μm ZrO 2 , the thickness of the high-resistance layer is 0.5 μm, the adhesive is epoxy silane, the median particle size of lithium metal particles is 4 μm, and the resistance per unit area of the obtained anode sheet is 0.5Ω / mm 2 ; Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0027] Embodiment 3: the anode active material is silicon oxide alloy (Si a o b m c , a=c=0, b=0.95) and graphite mixture, the high resistance material used in the high resistance layer is 2μm BaSO 4 The mixture, the binder is a mixture of diaminosilane and vinyl silane, the thickness of the high resistance layer is 5 μm, the median particle size of lithium metal particles is 20 μm, and the resistance per unit area of the obtained anode sheet is 2Ω / mm 2 ; Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Value particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com