Preparation method of CdTe sputtering target material

A technology of sputtering targets and hot pressing temperature, which is applied in the field of solar cell materials, can solve the problems of inability to produce high-quality CdTe targets, large grain size, and difficult cutting of materials, and achieve shortened preparation time, low equipment prices, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

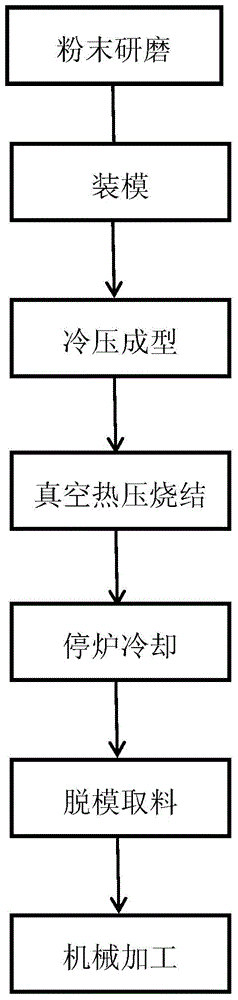

[0036] 1. Put the high-purity CdTe powder with a purity of 5N into a high-purity graphite mold and cold-press to form it. The pressure is 20-80 MPa, the temperature is room temperature, and the time is 20-50 minutes. After cold-pressing, vacuum sintering process is carried out; The particle size X50 (the corresponding particle size when the cumulative powder distribution is 50%) is 3-5 μm.

[0037] 2. The heating process is divided into two stages: the first stage is from room temperature to 450°C, and the heating rate is 15-25°C min -1 , keep warm for 5-20min after reaching 450°C; the second stage is from 450°C to hot pressing temperature, pressurization starts as the temperature rises, and the heating rate is 8-12°C·min -1 .

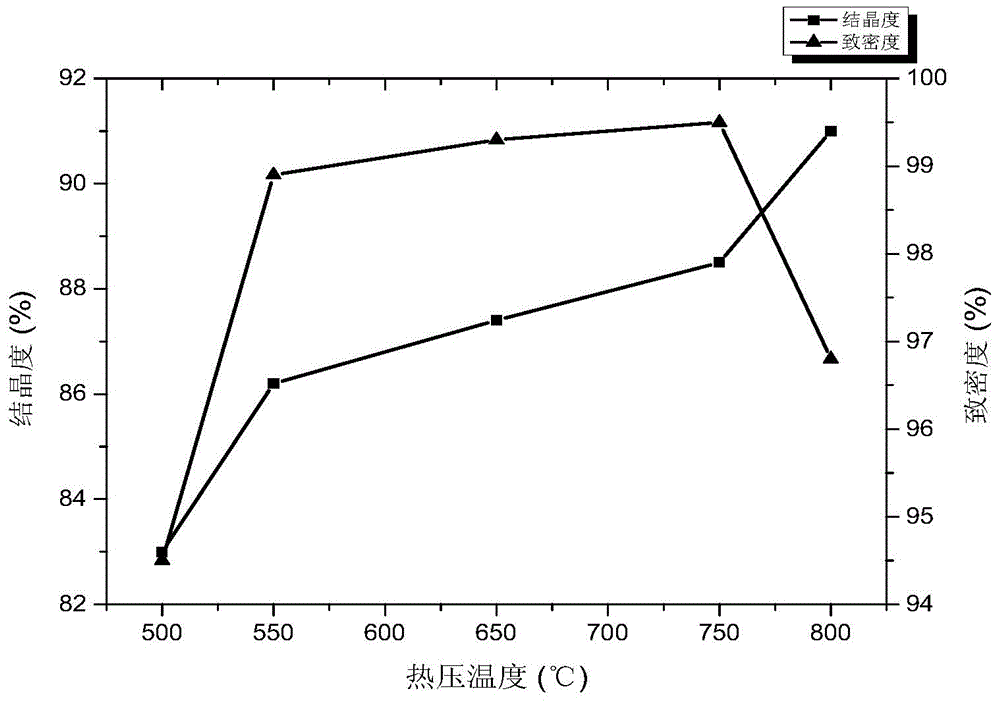

[0038] 3. After the temperature rises to the target temperature, the pressure will reach the appropriate pressure, and then heat preservation and pressure preservation will start. The temperature at this stage is 500-800°C, and the heat preservation a...

Embodiment 10~11

[0044] In order to obtain the preparation temperature range of the CdTe target material, low temperature and high temperature experiments were carried out respectively, and compared with Examples 1-9.

[0045] 1. The same as in Examples 1-9, put 5N high-purity CdTe powder into a high-purity graphite mold and cold-press molding, the cold-press pressure is 20-80MPa, the temperature is room temperature, and the cold-press time is 20-50min. Carry out vacuum sintering process.

[0046] 2. The heating process is divided into two stages: the first stage is from room temperature to 450°C, and the heating rate is 15-25°C min -1 , keep warm for 5-20min after reaching 450°C; the second stage is from 450°C to hot pressing temperature, pressurization starts as the temperature rises, and the heating rate is 8-12°C·min -1 .

[0047] 3. After the temperature rises to the target temperature, the pressure reaches the target pressure, and then heat preservation and pressure maintenance are sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com