High-temperature resisting precoated sand for casting

A technology of coated sand and high temperature resistance, applied in the field of coated sand, can solve the problems of unfavorable wide application, high preparation cost, limited application range, etc., to prevent molten iron from penetrating into the sand core, slow down the decomposition speed, and reduce the manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

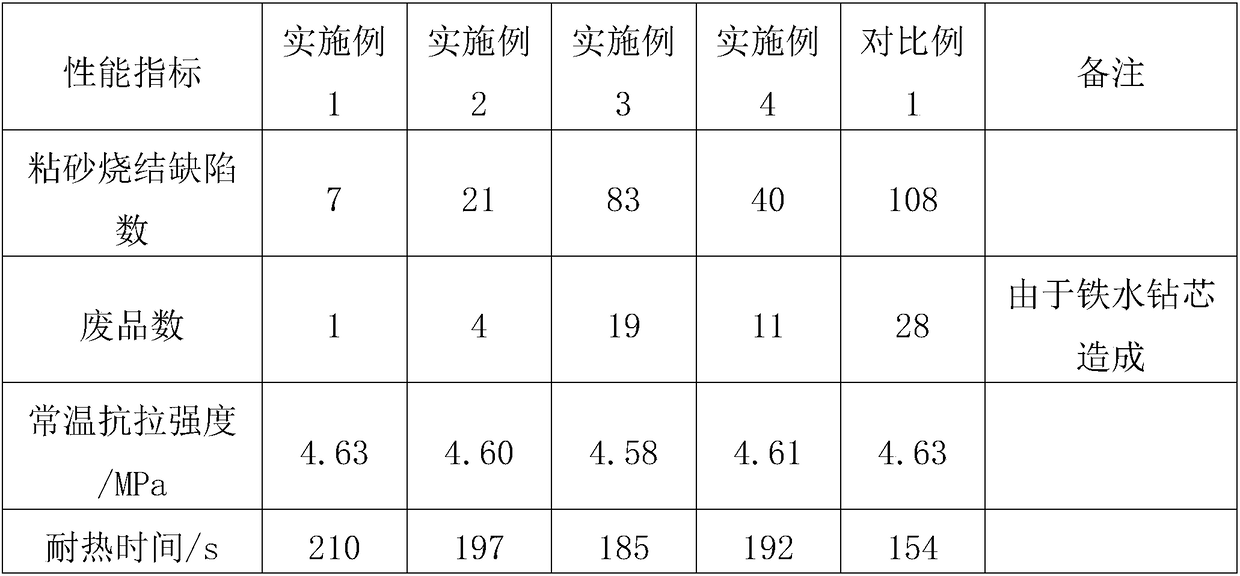

Examples

Embodiment 1

[0017] A high-temperature-resistant coated sand for casting, which is prepared from the following raw materials in parts by weight: 98 parts of raw sand, 2 parts of phenolic resin, 0.35 part of urotropine, 0.2 part of calcium stearate, and 0.3 part of hollow ceramic microspheres .

[0018] The high temperature resistant coated sand of this example is prepared by the following steps: (1) preheat the raw sand to 105°C, add it into the sand mixer, and control the speed of the sand mixer to 250r / min; (2) add Mix the phenolic resin for 20 seconds until the resin is melted and fully coated, then add hollow ceramic microspheres and mix for 75 seconds; (3) add water and mix for 85 seconds, then add urotropine and mix for 110 seconds until the water evaporates; (4) add stearic acid Calcium is mixed for 145s, cooled, sieved, tested, and packaged to obtain coated sand.

Embodiment 2

[0020] A high-temperature-resistant coated sand for casting, prepared from the following raw materials in parts by weight: 97 parts of raw sand, 2.5 parts of phenolic resin, 0.4 part of urotropine, 0.18 part of calcium stearate, and 0.2 part of hollow ceramic microspheres .

[0021] The high temperature-resistant coated sand in this example is prepared by the following steps: (1) preheat the raw sand to 110°C, add it into the sand mixer, and control the speed of the sand mixer to 220r / min; (2) add Mix the phenolic resin for 24 seconds until the resin is melted and fully coated, then add hollow ceramic microspheres and mix for 70 seconds; (3) add water and mix for 81 seconds, then add urotropine and mix for 115 seconds until the water evaporates; (4) add stearic acid Calcium is mixed for 150s, cooled, sieved, tested, and packaged to obtain coated sand.

Embodiment 3

[0023] A high-temperature-resistant coated sand for casting, prepared from the following raw materials in parts by weight: 98 parts of raw sand, 2.4 parts of phenolic resin, 0.3 part of urotropine, 0.15 part of calcium stearate, and 0.1 part of hollow ceramic microspheres .

[0024] The high temperature-resistant coated sand in this example is prepared by the following steps: (1) Preheat the raw sand to 100°C, add it to the sand mixer, and control the speed of the sand mixer to 240r / min; (2) add Mix the phenolic resin for 20 seconds until the resin is melted and fully coated, then add hollow ceramic microspheres and mix for 72 seconds; (3) add water and mix for 80 seconds, then add urotropine and mix for 112 seconds until the water evaporates completely; (4) add stearic acid Calcium is mixed for 145s, cooled, sieved, tested, and packaged to obtain coated sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com