Intelligent dual-power tobacco flue-curing barn

A dual-power, tobacco technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that the temperature adjustment is not precise and stable, the output power can only be controlled in sections, and the heating efficiency is low, so as to achieve easy automatic control and environmental protection, Easy and smooth temperature control and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

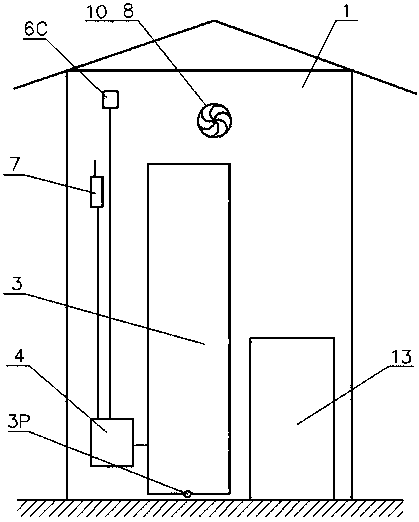

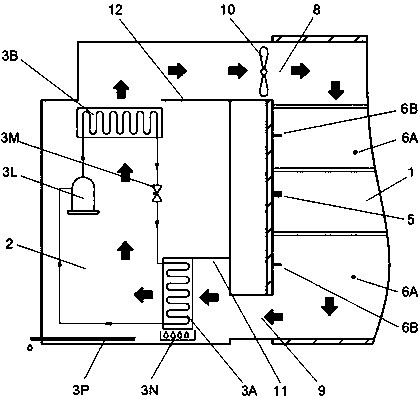

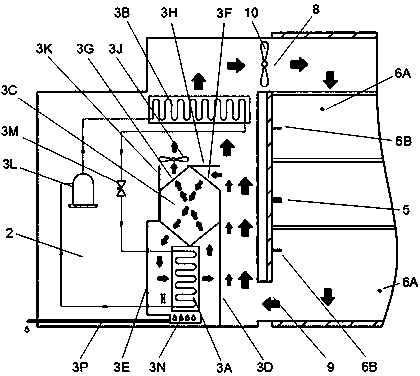

[0020] Such as figure 1 , 2 As shown in and 3, the present invention includes a flue-cured tobacco chamber 1, a heating chamber 2, a heat pump unit 3, a biomass fuel furnace 13, a field controller 4, an infrared spectrum analyzer 5, a temperature and humidity detection system, and a data transmission device 7. The heating The room 2 is airtight and adjacent to the flue-cured tobacco room 3, and the upper part of the heat insulation wall is provided with an air inlet 8 and the lower part is provided with a return air outlet 9. The heat pump evaporator 3A of the heat pump unit 3 is arranged on the air return port 9, the heat pump condenser 3B of the heat pump unit 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com