Baking technology effectively avoiding phenomenon that dust is hung on tobacco leaves at upper portion

A curing process and tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large degree of randomness, poor standardization, low industrial availability, and many operation errors, so as to reduce the perception of curing errors and save labor costs. , Improve the effect of baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

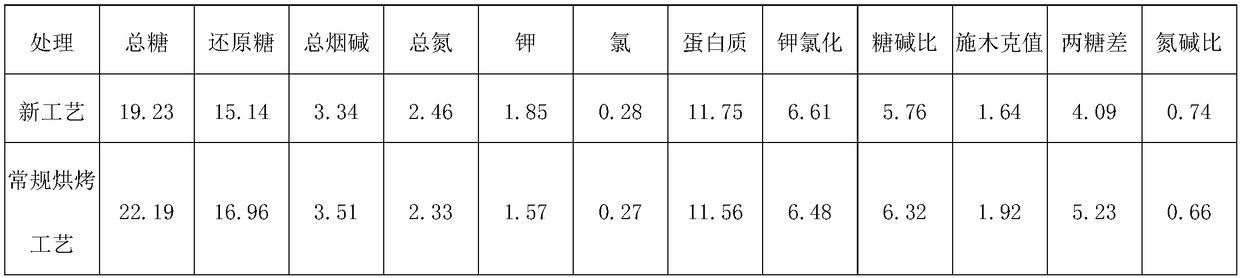

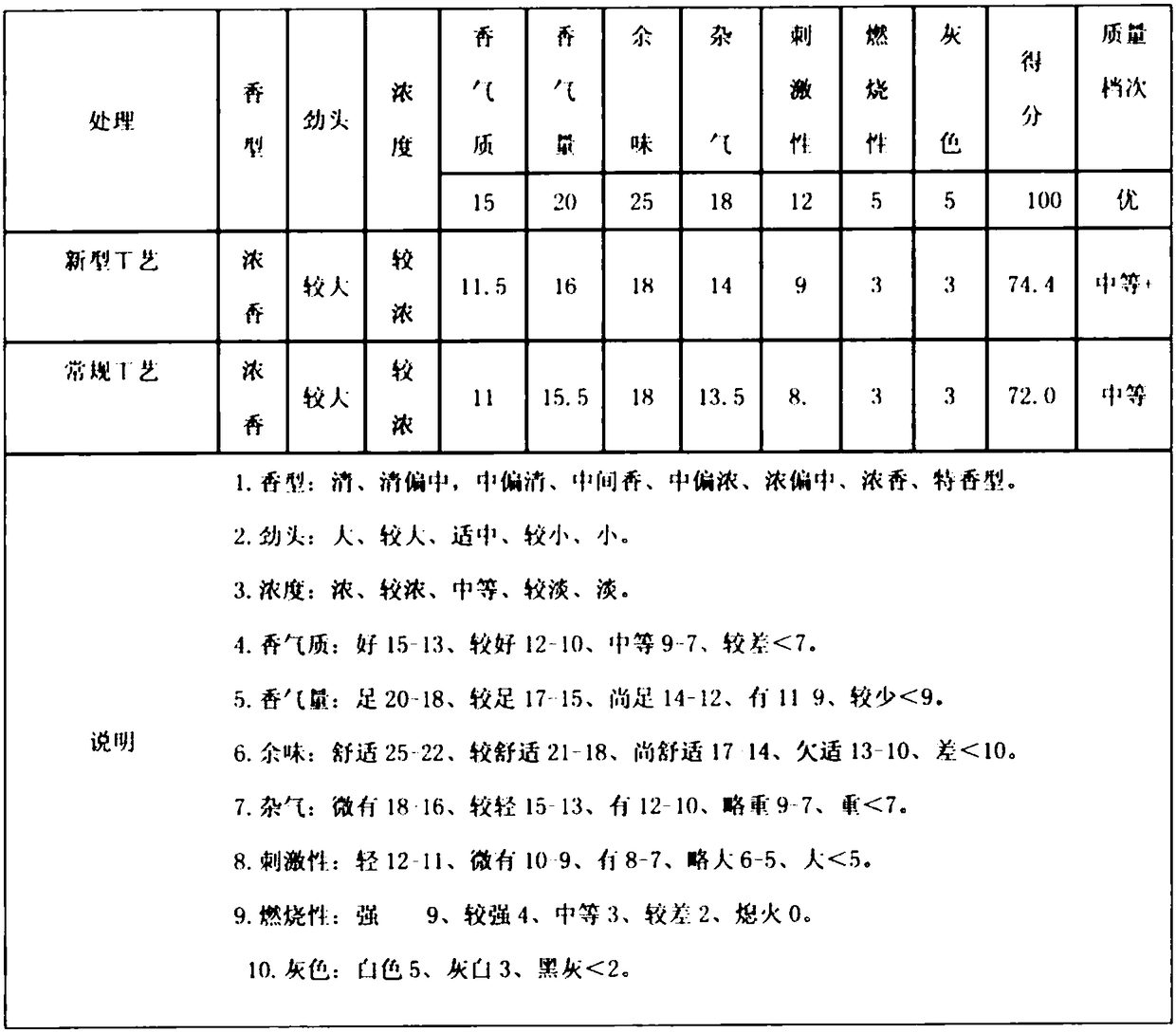

[0021] see Figure 1 ~ Figure 4 , the present invention provides a technical solution: a baking process that effectively solves the phenomenon of hanging ash on the upper tobacco leaves, adopts the tobacco rod weaving method, and is divided into 9 stages according to the changing state of the tobacco leaves in the baking process: the leaves turn yellow 7-8 In the mature stage, the tip and edge of the leaf become soft, the leaves turn yellow 90%, the mesolayer tobacco leaves start to curl the edge, the yellow veins, the mesolayer tobacco leaves reach the small tube stage, the branch veins of the tobacco leaves are all yellow, and the mesolayer leaves are dry 2 / 3 stage, the yellow tendons of the tobacco leaves, the stage of the leaves being complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com