Recovery system for metal in slag of high-carbon ferro-chrome electric furnace

A recovery system and electric furnace slag technology, which is applied in the field of slag separation and recovery system, can solve problems such as high labor intensity, difficulty in meeting standards, and environmental pollution, and achieve the effects of reduced labor intensity, high production efficiency, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

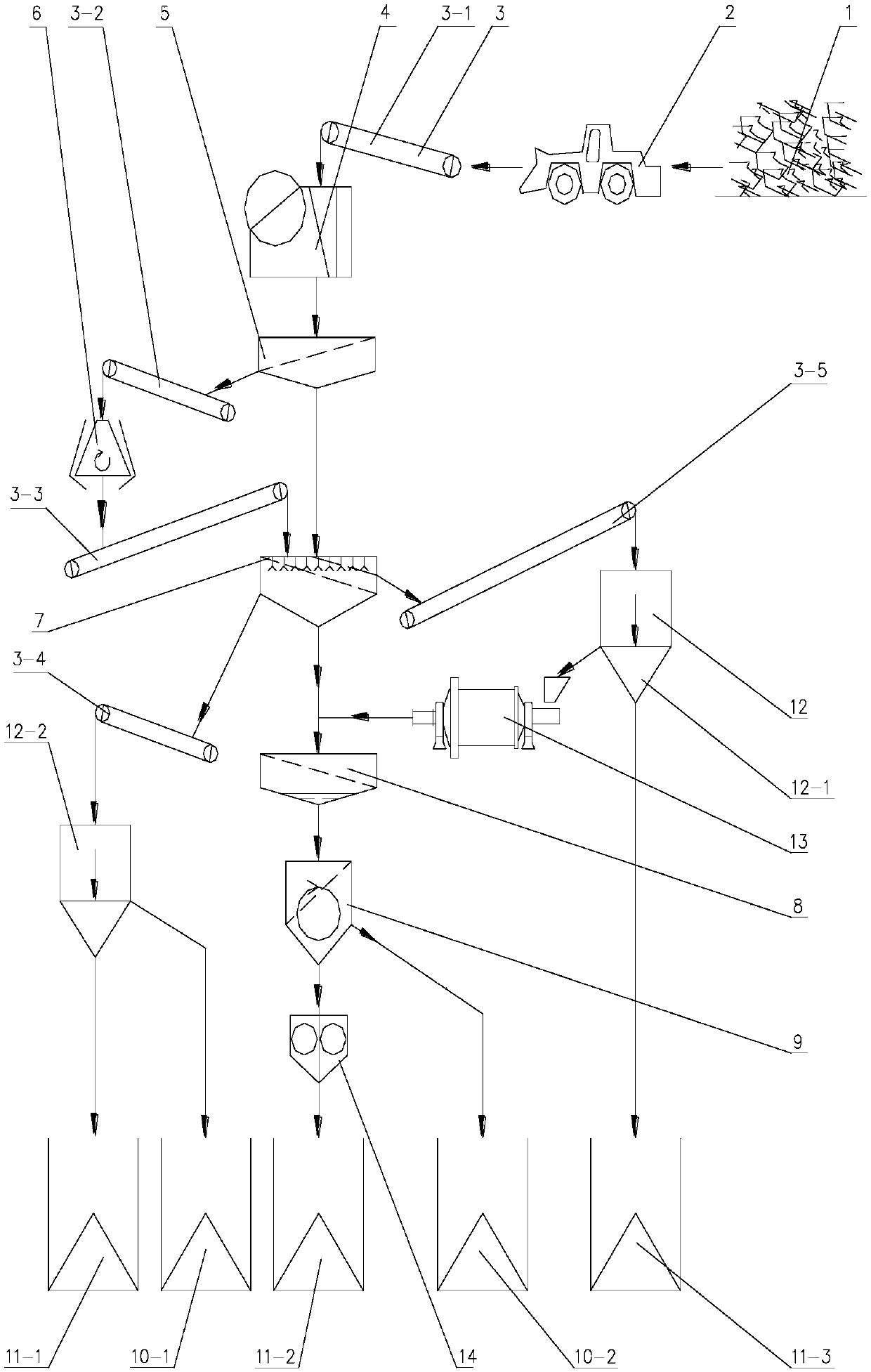

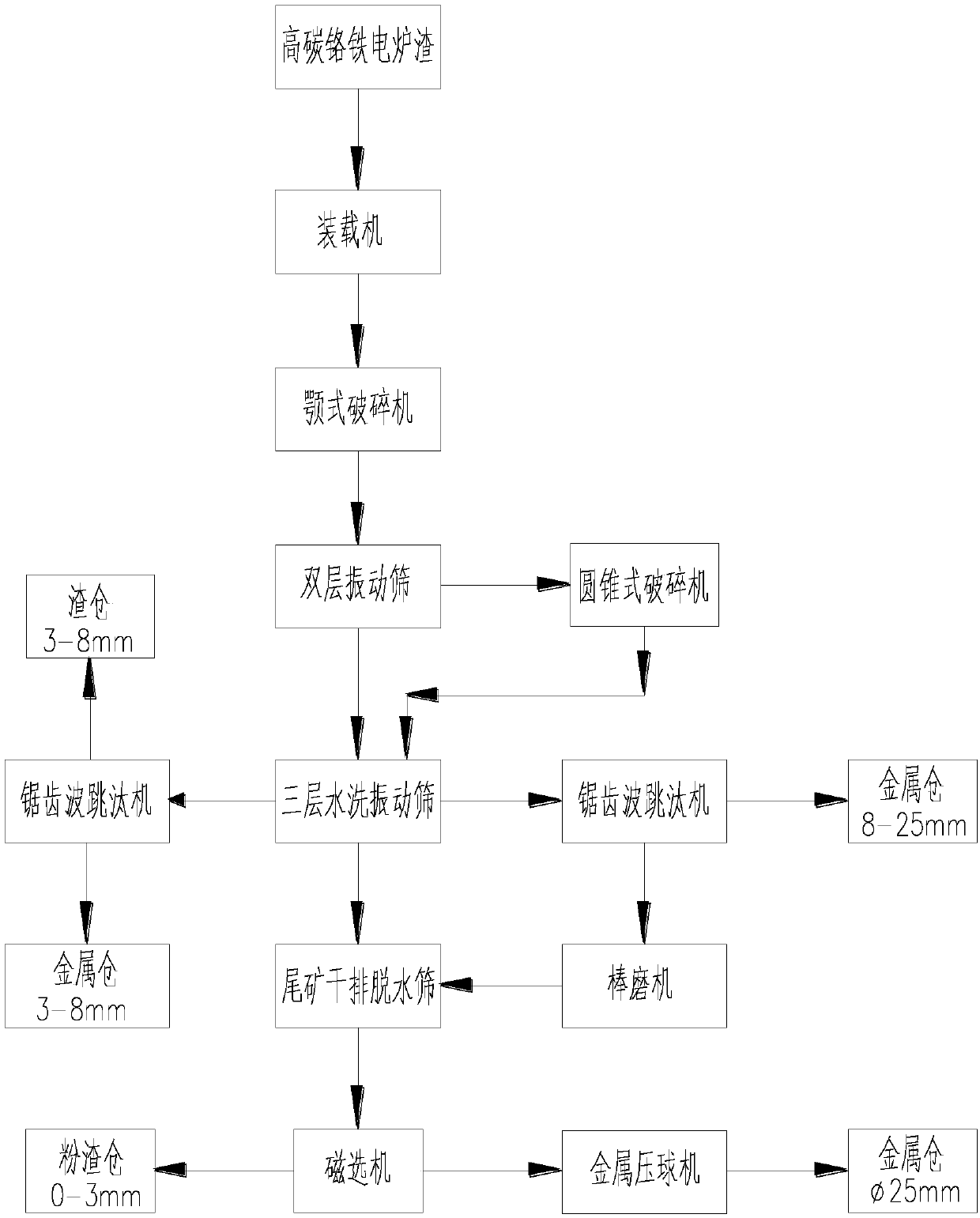

[0043] The specific embodiment of the present invention is as shown in the accompanying drawings, the high-carbon ferrochrome electric furnace slag metal recovery system includes: conveyor 3, jaw crusher 4, double-layer vibrating screen 5, cone crusher 6, three-layer washing screen 7, Tailings dry row dewatering screen 8, magnetic separator 9, slag bin 10, metal bin 11, sawtooth wave jig 12, rod mill 13 and ball press 14;

[0044] The inlet end of the jaw crusher 4 is located at the lower part of the output end of the conveyor A3-1, and the outlet end communicates with the inlet end of the double-layer vibrating screen 5;

[0045] The two outlets of the double-layer vibrating screen 5 communicate with the inlet end of the three-layer vibrating screen 7 and the inlet end of the conveyor B3-2 respectively;

[0046] The outlet end of the conveyor B3-2 is located above the inlet end of the cone crusher 6, the outlet end of the cone crusher 6 is located above the inlet end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com