Radiating method in sponge titanium producing process by magnesium method

A heat dissipation method and sponge titanium technology, which are applied in the field of heat dissipation in the process of producing titanium sponge by magnesium method, can solve the problems that the reduction feeding speed cannot be increased and the reaction temperature is high, so as to reduce the reduction time, improve the reduction feeding speed, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

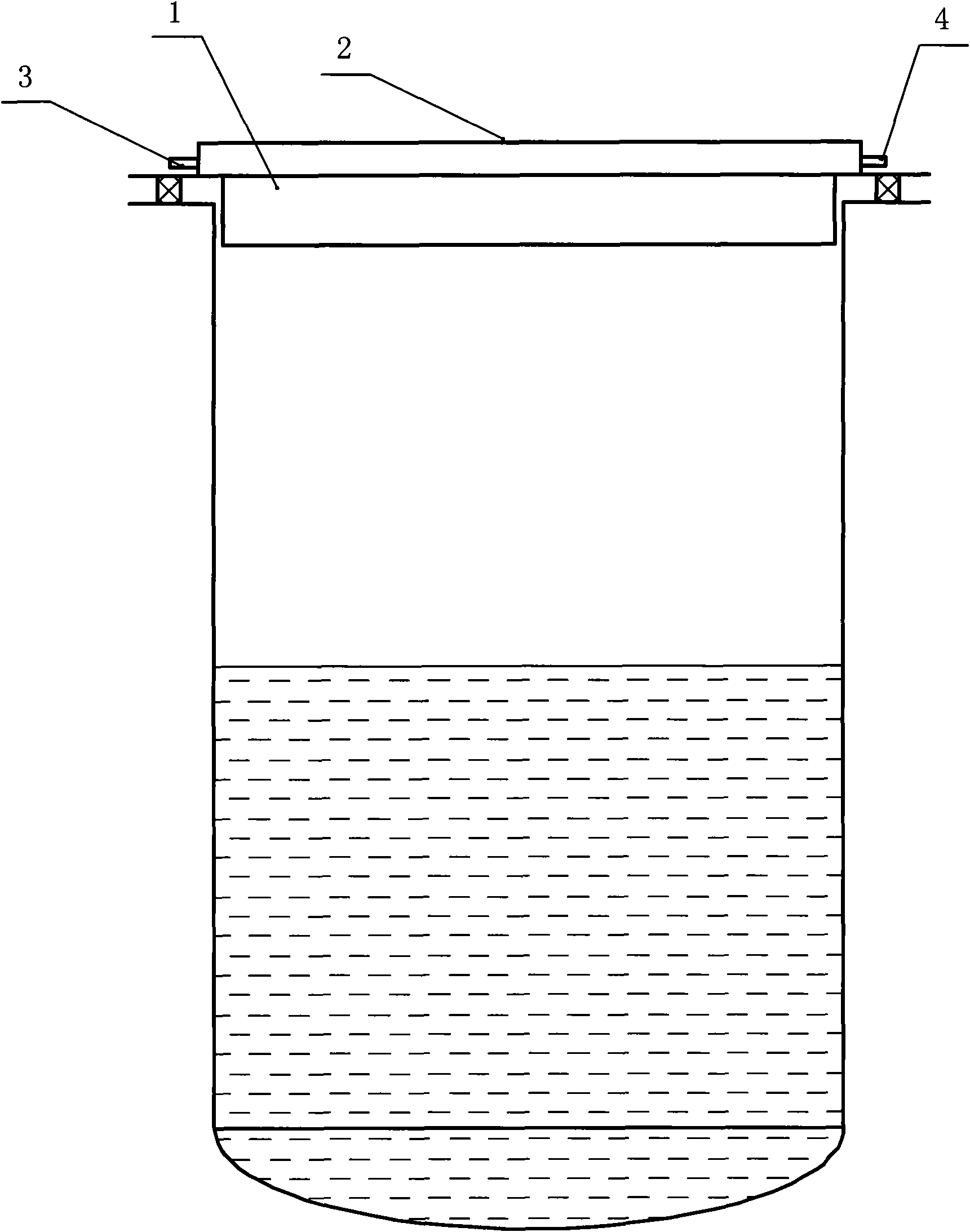

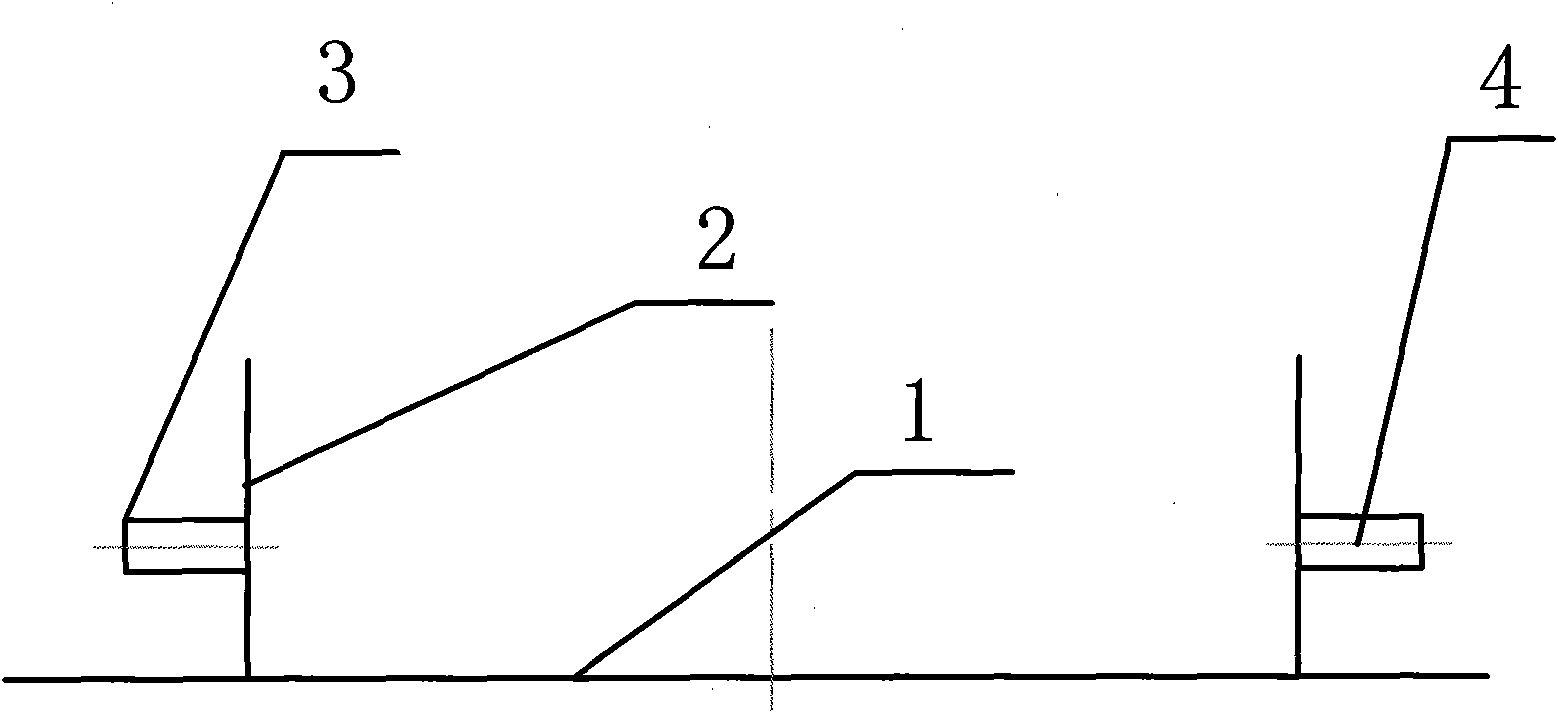

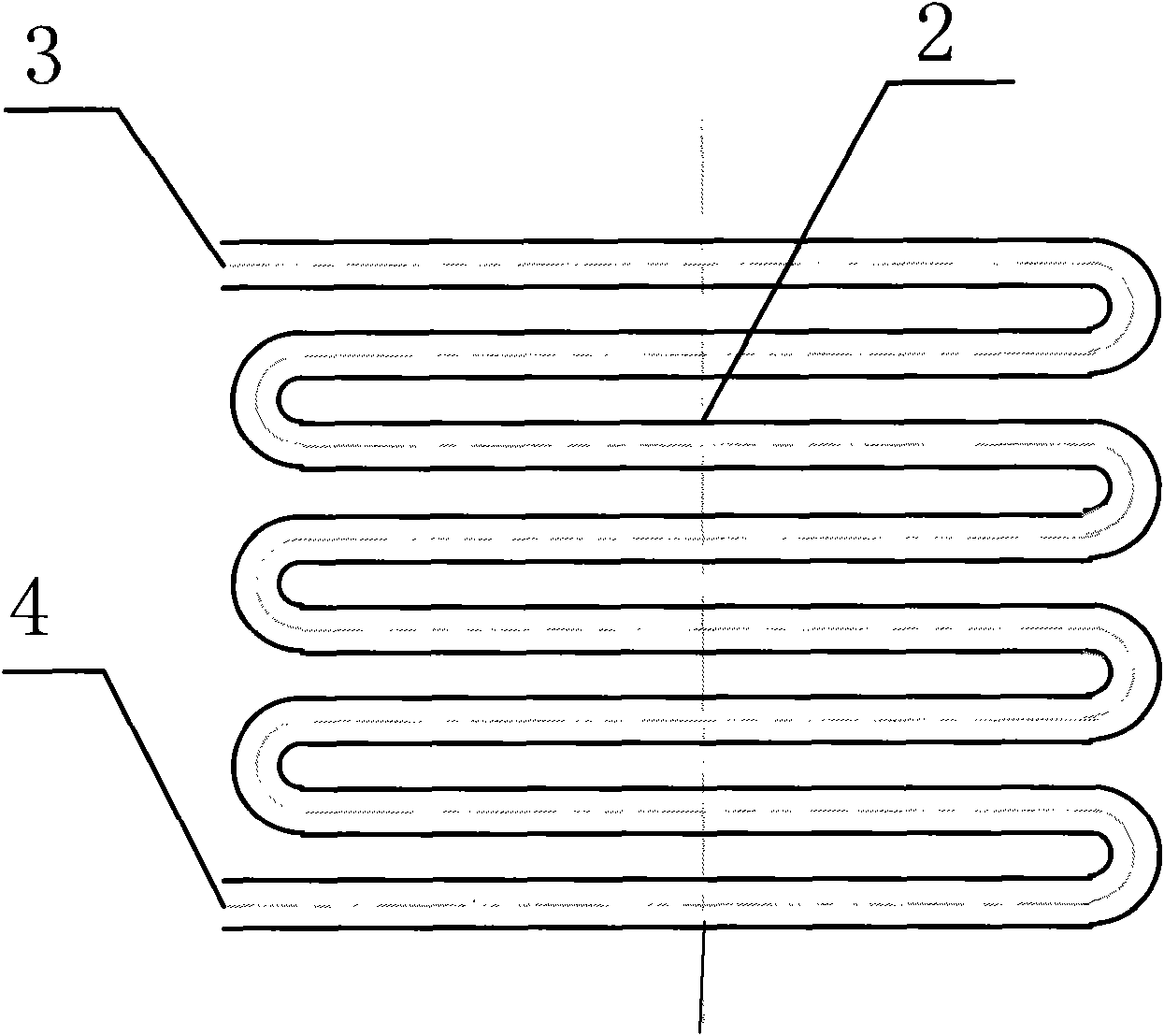

[0022] Such as figure 1 As shown, a heat dissipation method in the process of producing sponge titanium by a magnesium method is characterized in that a heat dissipation device 2 is provided on the reactor cover 1, and during reduction, a cooling medium is continuously introduced into the heat dissipation device 2 to achieve The large cover of the device is used for heat dissipation.

[0023] Utilize the method of the present invention, when sponge titanium is reduced, because reaction liquid surface temperature is higher (generally about 950 DEG C), heat mainly directly radiates on the big reactor cover by heat radiation, the temperature of reactor big cover rises sharply, The cooling medium is continuously fed into the cooling medium inlet 3 of the cooling device 2, and the cooling medium flows out from the cooling medium outlet 4, so as to realize effective heat exchange and achieve the heat dissipation effect in the reduction process of titanium sponge production.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com