Reducing device for producing titanium sponge

The technology of sponge titanium and reactor is applied in the field of reduction device used for producing sponge titanium by magnesium reduction method, which can solve the problems of increased energy consumption of sponge titanium, long reduction time, compact product structure, etc., so as to reduce the reduction feeding time and improve the The effect of reducing the feeding speed and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

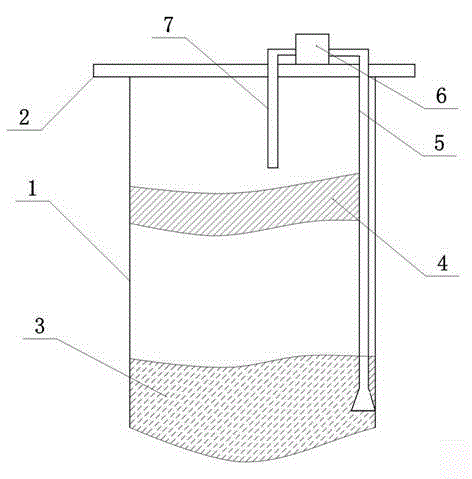

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a reduction device for producing sponge titanium is mainly composed of a reactor 1, a reactor cover 2, etc., a circulating pump 6 is arranged on the reactor cover 2, and a feed pipe 5 is inserted into the reactor through the reactor cover 2 In the molten magnesium chloride zone 3 at the lower part, the discharge pipe 7 is inserted into the upper part of the reaction zone 4 of the reactor 1 through the reactor cover 2, and the lower end of the feed pipe 5 is an open structure.

[0014] Utilize the device of the present invention, because feed pipe 5 lower ends are open structure, under the work of circulating pump 6, can directly deliver the molten magnesium chloride of reactor 1 bottom to the reaction zone 4 of reactor 1 top, make upper, lower The lower part of the molten magnesium chloride has realized circulation, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com