Embossing blanket products and production technique thereof, special device

A technology of production process and special equipment, which is applied in the field of acrylic blankets and polyester blankets, can solve the problems of small color spots, discoloration, economic loss, and downgrading of blankets, and achieve the effect of improving grades, increasing grade rates, and creating economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

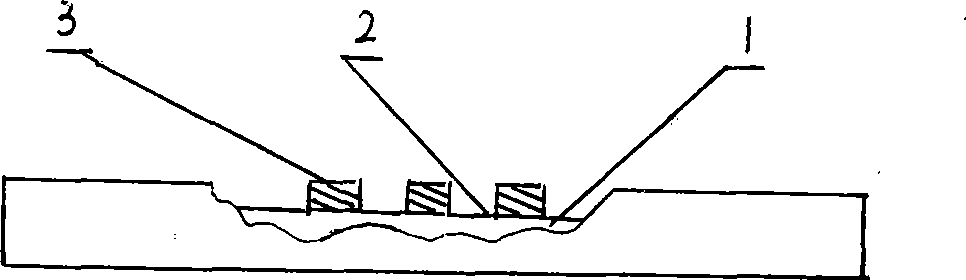

[0017] from figure 1 It can be seen from the figure that an embossed blanket product includes a blanket bottom surface 1, the difference of which is formed by the concave surface 2 and the convex surface 3 to form different patterns.

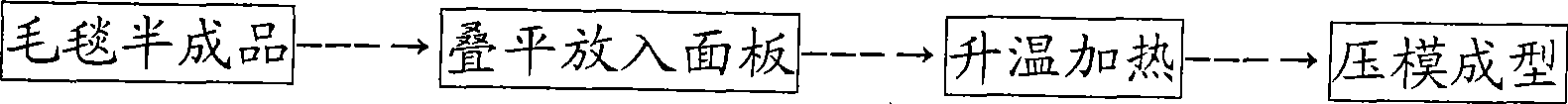

[0018] from figure 2 It can be seen from the above, a production process of embossed blanket products, put a blanket with a specification of 1400X1000mm on the panel of the embossing machine to heat up through the electric heating tube 10, and when the temperature rises to 120 ° C, through the synchronous action of four oil cylinders 8, The mold 9 on the large plate 7 moves downwards and starts embossing closely with the blanket, and the temperature will remain at 120°C--130°C, and an acrylic embossed blanket can be molded in 25 seconds.

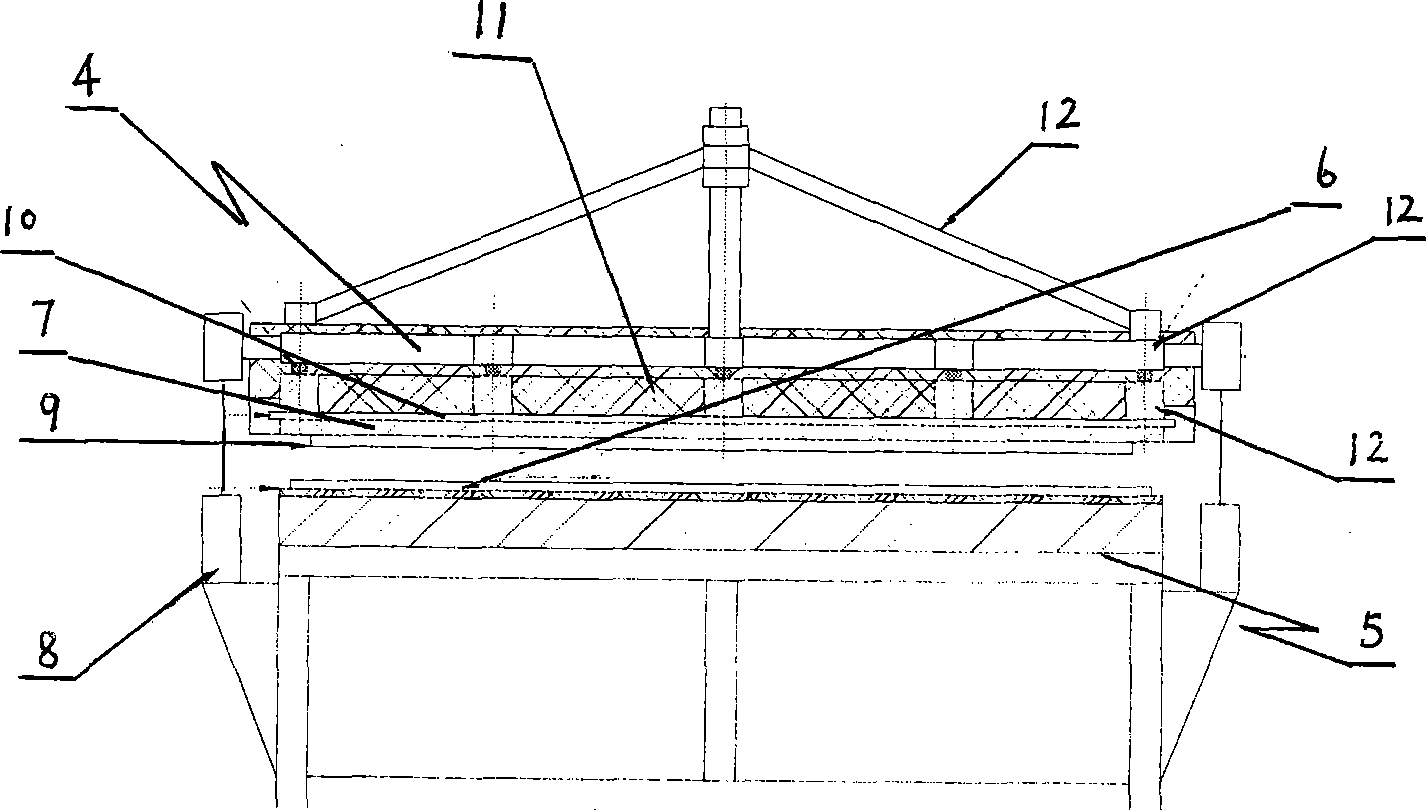

[0019] from image 3 It can be seen from the figure that a special equipment for producing embossed blanket products is formed by casting the upper frame 4 and the lower frame 5, and four oil cylinders 8 ar...

Embodiment 2

[0021] from figure 2 It can be seen from the above that a production process of embossed blanket products is to put a blanket with a specification of 1850X1850mm on the panel 6 of the embossing machine to raise the temperature through the electric heating tube 10, and when the temperature rises to 170°C, the synchronous action of the four oil cylinders 8 , the mold 9 on the large plate 7 moves downwards and starts to emboss closely with the blanket, and the temperature will remain at 120°C--130°C, and a polyester embossed blanket can be molded in 25 seconds.

Embodiment 3

[0023] from figure 2 As can be seen from the above, a production process of embossed blanket products, the blanket with a specification of 2000X2400mm is placed on the panel 6 of the embossing machine to heat up through the electric heating tube 10, and when the temperature rises to 220°C, the synchronous action of four oil cylinders 8 , the mold 9 on the large plate 7 moves downwards and starts to emboss closely with the blanket, and the temperature will remain at 180°C--220°C, and a polyester embossed blanket can be molded in 10 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com