Out-of-furnace process for producing high-silicon manganese silicon

A production process, the technology of the out-of-furnace method, which is applied in the field of high-silicon-manganese-silicon alloy production by shaking ladles, can solve the problems of low grade rate, high power consumption, and high production cost, and achieve stable product quality, simple operation, and high grade rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

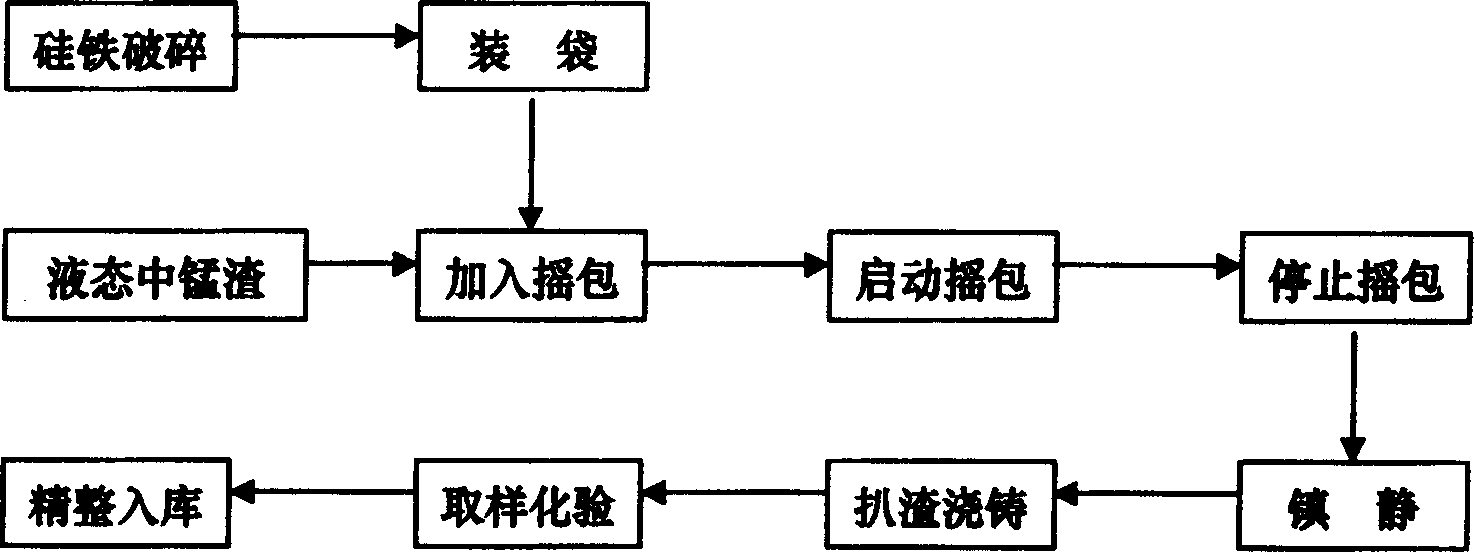

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, 600 kilograms of 75% ferrosilicon is crushed and processed into a particle size of 8 mm; 4400 kilograms of manganese slag is taken in a liquid state, its manganese Mn content is 18%, the alkalinity is 1.0, and the storage temperature is 1480 ° C for subsequent use; the above raw materials are poured into the shaker successively In the bag, shake the bag for 15 minutes, calm down for 10 minutes, remove slag, cast, finish and put it into storage.

Embodiment 2

[0017] Example 2, take 700 kg of 65% ferrosilicon and crush it into a particle size of 6mm, 4400 kg of manganese slag in the liquid state, its manganese Mn content is 19%, the alkalinity is 1.2, and the storage temperature is 1500 ° C for later use; the above raw materials are poured into the shaking bag successively Inside, run the shaker for 15 minutes, calm down for 10 minutes, remove slag, cast, finish and put into storage.

Embodiment 3

[0018] Example 3: Take 500 kg of crystalline silicon and crush it into a particle size of 9 mm, 4,400 kg of manganese slag in liquid state, its manganese Mn content is 20%, the alkalinity is 1.2, and the storage temperature is 1510° C. Run the shaker for 12 minutes, calm down for 10 minutes, remove slag, cast, finish and store.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com