Flotation method of vulcanizing lead and zinc by weak acid full pulp

A lead-zinc sulfide and weak acid technology, which is applied in flotation, solid separation, etc., can solve the problems of low economic benefit, environmental protection benefit and social benefit, difficult operation and control, and high production cost, and achieve the reduction of flotation reagents and auxiliary materials and dosage, the type of medicine and the effect of less dosage, easy to operate and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

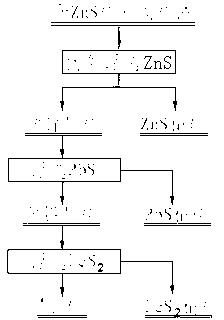

[0012] As shown in the figure, the present invention adopts weakly acidic full pulp flotation process to remove lead sulfide, zinc, FeS in lead-zinc ore or slag 2 float out. Will contain zinc sulfide and often lead sulfide, FeS 2 The ore or slag is flotation by the acidic full pulp flotation process, which is to grind the lead-zinc sulfide ore or slag to make a weakly acidic pulp with a pH value of 1 to 7, and then carry out Whole pulp flotation to get ZnS concentrate, PbS concentrate and FeS 2 concentrate. Flotation uses isopentyl xanthate as a collector for flotation of lead sulfide and zinc. The moisture content of the lead-zinc sulfide-containing ore or slag should not exceed 28%, and the zinc oxidation rate should not exceed 30%. Flotation of zinc-poor tailings produced by weakly acidic full pulp flotation to obtain ZnS concentrate and then flotation of PbS, and production of lead-poor tailings of PbS concentrate and flotation of FeS 2 , get FeS 2 concentrate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com