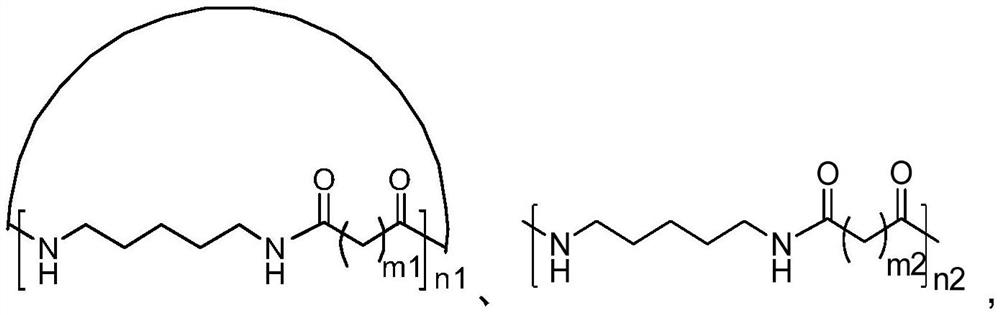

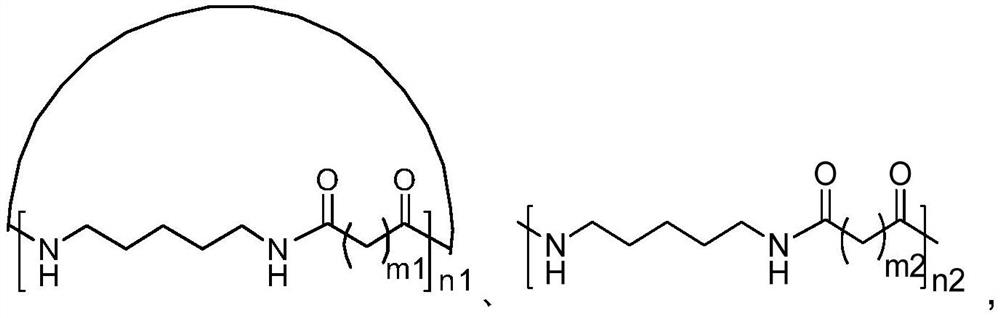

Polyamide 56 fiber with low boiling water shrinkage rate and preparation method and application of polyamide 56 fiber

A boiling water shrinkage, polyamide technology, applied in the field of polyamide materials, can solve problems such as difficulty in reducing boiling water shrinkage, and achieve the effects of reducing the greenhouse effect and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

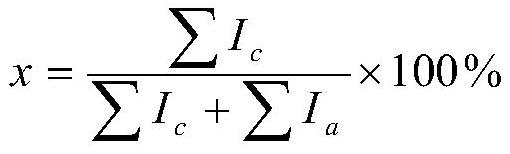

Method used

Image

Examples

Embodiment 1

[0085] Example 1: Preparation of low boiling water shrinkage polyamide 56 pre-oriented yarn

[0086] (1) The polyamide 56 resin is heated to a molten state by a screw to form a polyamide 56 melt.

[0087] (2) The polyamide 56 melt is transported to the spinning box through the melt pipeline, and after being accurately metered by the metering pump, it is injected into the spinning assembly and extruded from the spinneret hole.

[0088] (3) cooling, oiling, stretching and winding the extruded as-spun fibers to obtain the polyamide 56 pre-oriented filaments.

[0089] In step (1), the relative viscosity of the polyamide 56 resin is 2.5; the oligomer content of the polyamide 56 resin is 0.8wt%; the moisture content of the polyamide 56 resin is 800ppm; the number average molecular weight is 18000 , the molecular weight distribution is 1.6;

[0090] The screw is heated in four zones, wherein the temperature in the first zone is 250°C; the temperature in the second zone is 270°C; th...

Embodiment 2

[0095] Embodiment 2: Preparation of low boiling water shrinkage polyamide 56 pre-oriented yarn

[0096] (1) The polyamide 56 resin is heated to a molten state by a screw to form a polyamide 56 melt.

[0097] (2) The polyamide 56 melt is transported to the spinning box through the melt pipeline, and after being accurately metered by the metering pump, it is injected into the spinning assembly and extruded from the spinneret hole.

[0098] (3) cooling, oiling, stretching and winding the extruded as-spun fibers to obtain the polyamide 56 pre-oriented filaments.

[0099] In step (1), the relative viscosity of the polyamide 56 resin is 2.7; the oligomer content of the polyamide 56 resin is 1.0wt%; the moisture content of the polyamide 56 resin is 900ppm; the number average molecular weight is 19000 , the molecular weight distribution is 1.8;

[0100]The screw is heated in four zones, wherein the temperature in the first zone is 255°C; the temperature in the second zone is 270°C; ...

Embodiment 3

[0105] Embodiment 3: Preparation of low boiling water shrinkage polyamide 56 pre-oriented yarn

[0106] (1) The polyamide 56 resin is heated to a molten state by a screw to form a polyamide 56 melt.

[0107] (2) The polyamide 56 melt is transported to the spinning box through the melt pipeline, and after being accurately metered by the metering pump, it is injected into the spinning assembly and extruded from the spinneret hole.

[0108] (3) cooling, oiling, stretching and winding the extruded as-spun fibers to obtain the polyamide 56 pre-oriented filaments.

[0109] In step (1), the relative viscosity of the polyamide 56 resin is 2.4; the oligomer content of the polyamide 56 resin is 1.15wt%; the moisture content of the polyamide 56 resin is 1000ppm; the number average molecular weight is 20000 , the molecular weight distribution is 1.7;

[0110] The screw is heated in four zones, wherein the temperature in the first zone is 250°C; the temperature in the second zone is 272°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com