Multi-point gas injection underground gasifier and multi-point gas injection underground gasification method

A technology of underground gasification and gas injection point, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of low output of gas products and large fluctuation of components, so as to increase the combustion working area, expand the production scale, and reduce the operation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

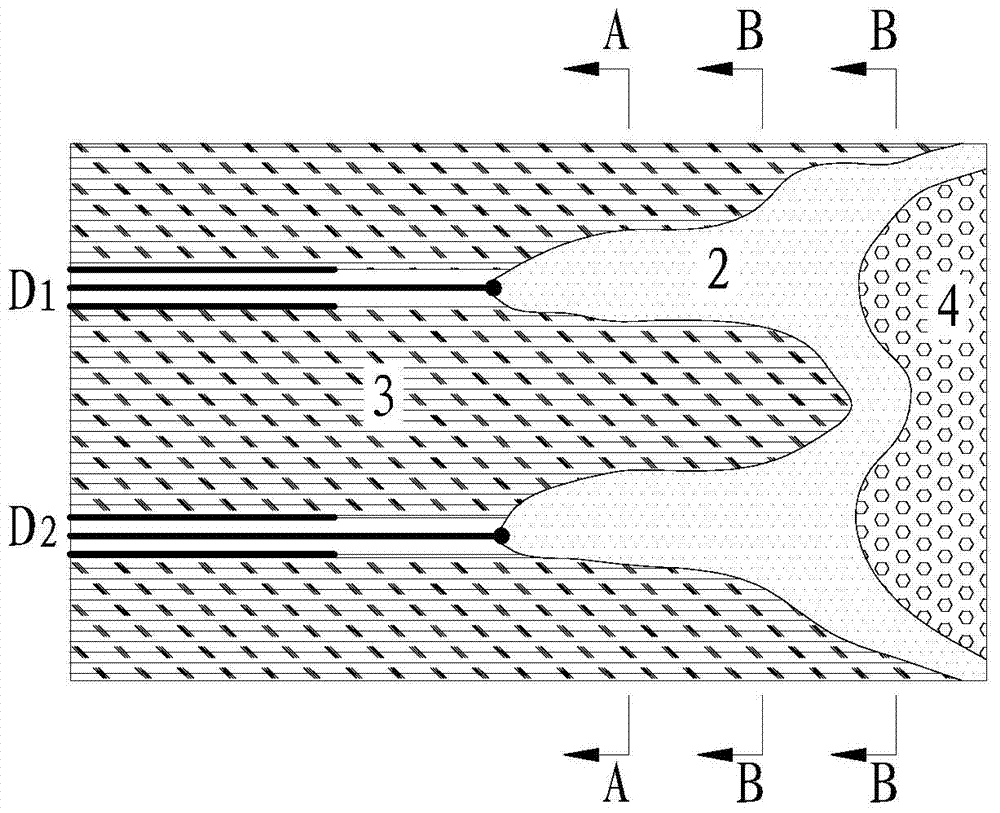

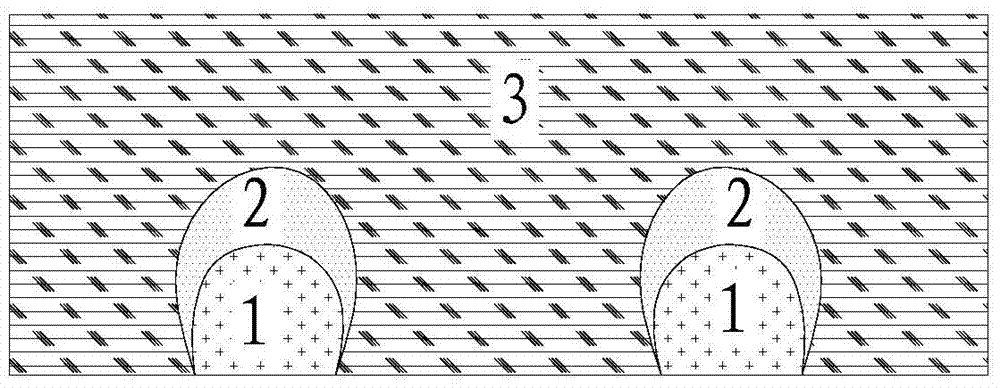

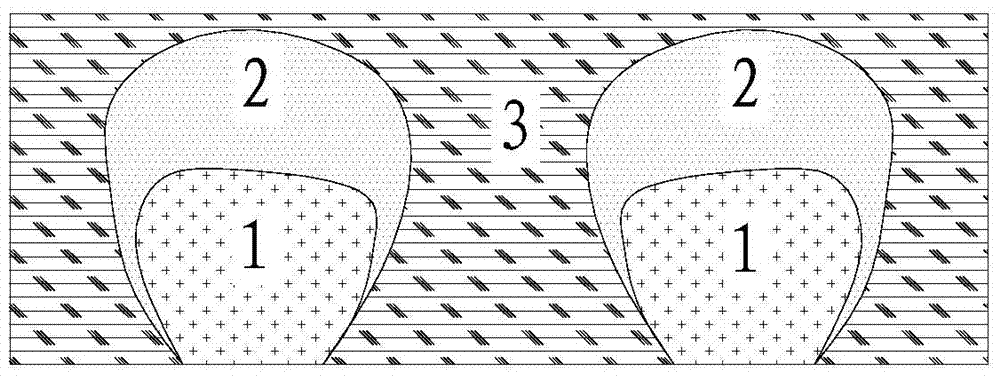

[0051] The multi-point gas injection underground gasifier provided in this embodiment is used for gasification mining of lignite coal seams with a low degree of metamorphism. Such as Figure 5 As shown, the buried depth of the coal seam to be gasified is 255 meters, the thickness of the coal seam is 10-12 meters, the inclination angle is less than 5 degrees, and the coal type is Inner Mongolia lignite. Including 11 directional wells, 8 vertical gas outlet wells and gasification channels, etc. The working face of the gasifier consists of two directional gas injection wells (D1, D2), such as Figure 5 As shown, it is arranged in parallel along the occurrence of the coal seam at a distance of 1.5 meters above the floor of the coal seam. The coal seam section is supported by glass fiber reinforced plastic screen pipes. The length of the horizontal section is 400 meters and the spacing is 20 meters.

[0052] The steps of using the gasifier of this embodiment to carry out undergro...

Embodiment 2

[0060] The multi-point gas injection underground gasifier provided in this embodiment is applied to low-metamorphism long-flame coal seams that are easy to underground gasify. The buried depth of the coal seam to be gasified is 520 meters, the thickness of the coal seam is 14-16 meters, the inclination angle is less than 8 degrees, and the coal type is long-flame coal. Such as Figure 6 The layout of the underground gasifier shown includes 7 directional wells, 5 vertical gas outlet wells and gasification channels. The working face of the gasifier is composed of three directional gas injection wells (D1, D2, D3), which are arranged in parallel along the coal seam occurrence and 1.0 meters away from the bottom plate. The coal seam section is supported by glass fiber reinforced plastic screen pipes. The distance is 16 meters.

[0061] The steps of using the gasifier of this embodiment to carry out underground gasification include:

[0062] 1) Firstly, establish gasification fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com