Method for treating waste water generated in ionic rare earth production

A technology for ionic rare earth and wastewater production, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of difficult biochemical or physicochemical treatment, soil salinization, water richness, etc. Nutritization and other issues, to achieve the effect of promoting the use, short reaction process, and thorough reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

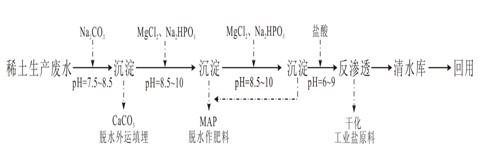

[0020] A rare earth production enterprise in Guangxi used hydrochloric acid to dissolve, extract and separate light, medium and heavy rare earth elements, and ammonium bicarbonate precipitation process to process rare earths, resulting in a large amount of high chlorine, high nitrogen, high oxalic acid, and high calcium rare earth production wastewater. According to environmental emission reduction requirements, rare earth production wastewater needs to be treated in accordance with the rare earth industrial pollutant discharge standard (GB26451-2011).

[0021] (1) Add sodium carbonate according to 120% of the molar concentration of calcium ions in rare earth production wastewater, adjust the pH value to 8.1, mix and stir for 15 minutes, and after 25 minutes of precipitation, remove 98% of calcium ions;

[0022] (2) Adjust the pH value of the supernatant to 9.2 after precipitation, and add magnesium chloride and disodium hydrogen phosphate at the same time according to the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com