Anti-wrinkle antibiotic finishing agent as well as preparation method and application thereof

An antibacterial finishing agent, the technology of weight percentage, applied in the direction of fiber treatment, fiber type, textile and papermaking, etc., can solve the problems of inability to effectively inhibit Candida albicans, strength changes, poor antibacterial effect, etc., to achieve enhanced anti-wrinkle performance, strong Inhibitory action, effect of high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

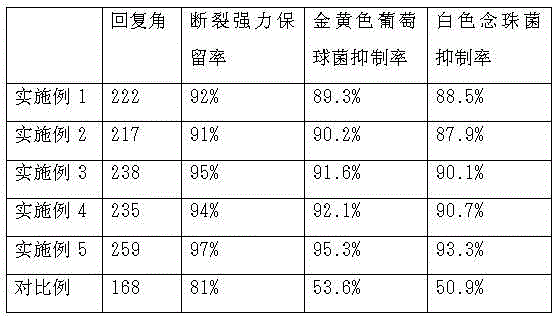

Examples

Embodiment 1

[0040] (1) Vacuum-dry the perilla seeds and mechanically pulverize them. Stir and extract the perilla seeds powder with ethyl acetate. The extraction temperature is 45°C, the extraction time is 3 hours, and the weight ratio of solid to liquid is 1:5. After extraction, stand still , taking the supernatant and concentrating it to obtain the prepared white perilla ethyl acetate extract; (2) drying the kaempferia and then pulverizing it with a pulverizer, stirring and extracting the kaewan powder with ethanol, the extraction temperature is 50°C, and extracting The time is 2 hours, the weight ratio of solid to liquid is 1:8, centrifuge after extraction, remove the lower layer of sediment, and concentrate the supernatant to obtain the prepared kaempferol ethanol extract; (3) Take azelaic acid as 2.6wt according to the weight percentage %, disodium hydrogen phosphate is 1.6wt%, carboxymethyl chitosan is 4wt%, hydroxypropyl-β-cyclodextrin is 5.6wt%, white perilla ethyl acetate extract ...

Embodiment 2

[0042] (1) Vacuum-dry the perilla seeds and mechanically pulverize them. Stir and extract the perilla seeds powder with ethyl acetate. The extraction temperature is 45°C, the extraction time is 3 hours, and the weight ratio of solid to liquid is 1:5. After extraction, stand still , taking the supernatant and concentrating it to obtain the prepared white perilla ethyl acetate extract; (2) drying the kaempferia and then pulverizing it with a pulverizer, stirring and extracting the kaewan powder with ethanol, the extraction temperature is 50°C, and extracting The time is 2 hours, the weight ratio of solid to liquid is 1:8, after extraction, centrifuge, remove the lower sediment, and concentrate the supernatant to obtain the prepared kaempferol ethanol extract; (3) Take azelaic acid as 0.8wt according to the weight percentage %, disodium hydrogen phosphate is 3.2wt%, carboxymethyl chitosan is 2.5wt%, hydroxypropyl-β-cyclodextrin is 3.3wt%, white perilla ethyl acetate extract is 3wt...

Embodiment 3

[0044] (1) Vacuum-dry the perilla seeds and mechanically pulverize them. Stir and extract the perilla seeds powder with ethyl acetate. The extraction temperature is 45°C, the extraction time is 3 hours, and the weight ratio of solid to liquid is 1:5. After extraction, stand still , taking the supernatant and concentrating it to obtain the prepared white perilla ethyl acetate extract; (2) drying the kaempferia and then pulverizing it with a pulverizer, stirring and extracting the kaewan powder with ethanol, the extraction temperature is 50°C, and extracting The time is 2 hours, the weight ratio of solid to liquid is 1:8, after extraction, centrifuge, remove the lower sediment, and concentrate the supernatant to obtain the prepared kaempferol ethanol extract; (3) Take azelaic acid as 1.2wt according to the weight percentage %, disodium hydrogen phosphate is 2.7wt%, carboxymethyl chitosan is 3.5wt%, hydroxypropyl-β-cyclodextrin is 5wt%, white perilla ethyl acetate extract is 4wt%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com