Rapid measurement reagent for manganese concentration in water and use method thereof

A technology for rapid determination and manganese concentration, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the influence on chemical indicators, etc. cumbersome and other problems, to achieve the effect of easy transportation and carrying, simple operation and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

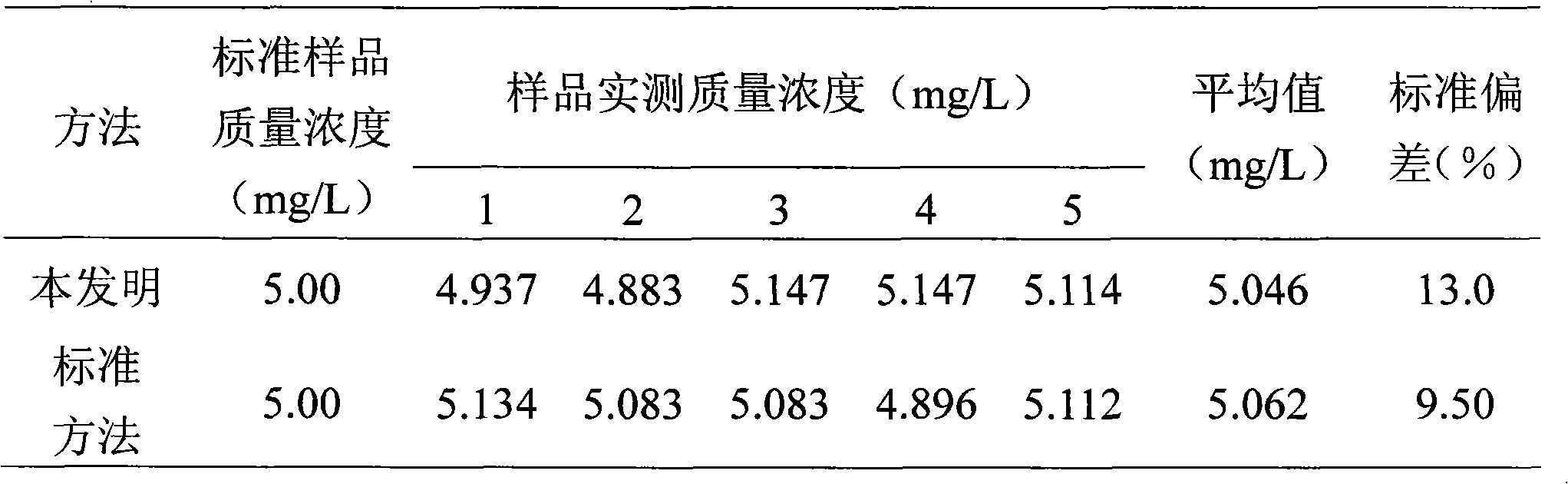

Examples

Embodiment 1

[0023] 1. Prepare 9g of anhydrous potassium pyrophosphate, 18g of anhydrous disodium hydrogen phosphate, 2.5g of citric acid, and 70.5g of anhydrous sodium sulfate, and add the above raw materials into a glass mortar, and grind them sufficiently so that all raw materials can pass through an 80-mesh standard sieve , and then sub-packed into 0.2g per package to become A reagent;

[0024] 2. Prepare 10g of potassium periodate and 90g of potassium chloride, add the above raw materials into a glass mortar, fully grind all the raw materials to pass through an 80-mesh standard sieve, and then pack them into 0.2g per pack to become reagent B.

[0025] 3. Add a pack of reagent A into the water sample, and after it dissolves, add a pack of reagent B. If the water contains manganese, it will display purple, and the depth of purple is proportional to the concentration of manganese in the water. After standing for 10 minutes, it will be compared with the standard Color comparison card, col...

Embodiment 2

[0027] 1. Prepare 5g of anhydrous potassium pyrophosphate, 10g of anhydrous disodium hydrogen phosphate, 0.5g of citric acid, and 65g of anhydrous sodium sulfate. Add the above-mentioned raw materials into a glass mortar and grind them sufficiently so that all raw materials can pass through an 80-mesh standard sieve. Then sub-package into 0.2g per pack to become reagent A;

[0028] 2. Prepare 5g of potassium periodate and 95g of potassium chloride, add the above raw materials into a glass mortar, fully grind all the raw materials to pass through an 80-mesh standard sieve, and then pack them into 0.2g per pack to become reagent B.

[0029] 3. Add a pack of reagent A into the water sample, and after it dissolves, add a pack of reagent B. If the water contains manganese, it will display purple, and the depth of purple is proportional to the concentration of manganese in the water. After standing for 10 minutes, it will be compared with the standard Color comparison card, color di...

Embodiment 3

[0031] 1. Prepare 15g of anhydrous potassium pyrophosphate, 30g of anhydrous disodium hydrogen phosphate, 5g of citric acid, and 80g of anhydrous sodium sulfate. Add the above-mentioned raw materials into a glass mortar, fully grind all raw materials to pass through an 80-mesh standard sieve, and then Divide into 0.2g per package and become reagent A;

[0032] 2. Prepare 25g of potassium periodate and 75g of potassium chloride, add the above raw materials into a glass mortar, fully grind all the raw materials to pass through an 80-mesh standard sieve, and then pack them into 0.2g per pack to become reagent B.

[0033] 3. Add a pack of reagent A into the water sample, and after it dissolves, add a pack of reagent B. If the water contains manganese, it will display purple, and the depth of purple is proportional to the concentration of manganese in the water. After standing for 10 minutes, it will be compared with the standard Color comparison card, color disc or colorimeter col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com