Small-taper high-quality efficient machining device and method for via holes in surface of packaging substrate

A technology for packaging substrates and via holes, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as laser shielding, scattering, reducing laser energy, and affecting the quality of via holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, a high-quality and high-efficiency processing method for small taper via holes on the surface of a packaging substrate, comprising the following steps:

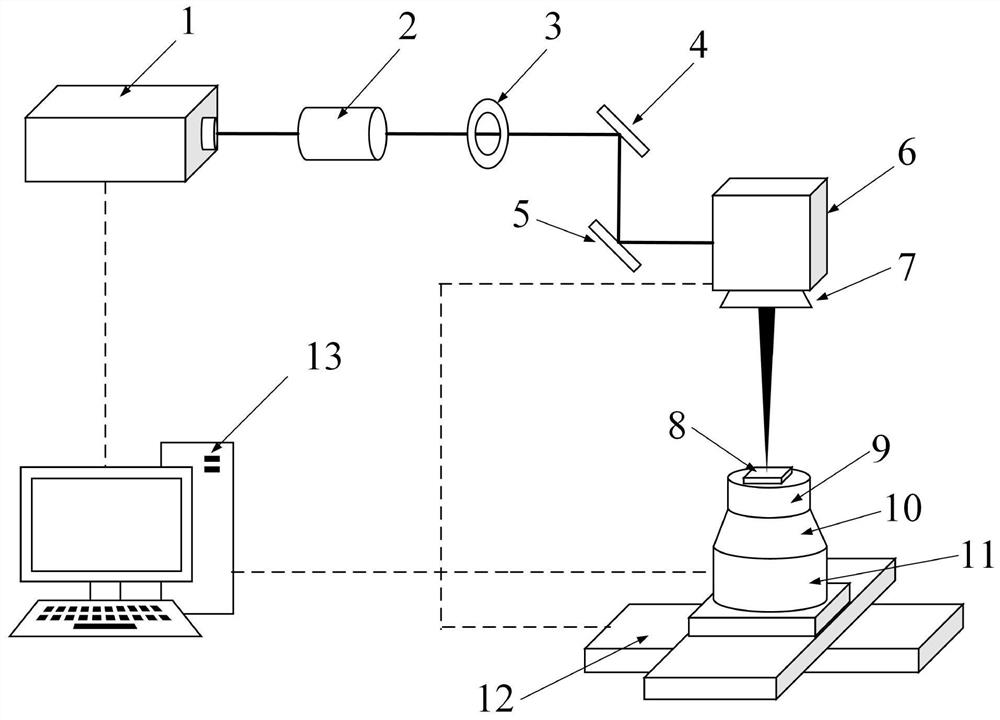

[0041]1) Build an ultrasonic-assisted laser processing system, such as figure 1 As shown, the ultrasonic-assisted laser processing system includes an optical path system and an ultrasonic vibration auxiliary device; the optical path system includes a short-pulse laser 1, and the laser beam output by the short-pulse laser 1 passes through a beam expander 2, a small aperture stop 3, and a first reflecting mirror in sequence. 4. The second reflector 5, the scanning galvanometer 6 and the focusing field mirror 7 act on the packaging substrate, the short pulse laser 1, the beam expander 2, the aperture diaphragm 3, the first reflector 4, and the second reflector 5. The scanning galvanometer 6 and the focusing field lens 7 form an optical path system; the short pulse laser 1 is a nanosecond laser, and the outpu...

Embodiment 2

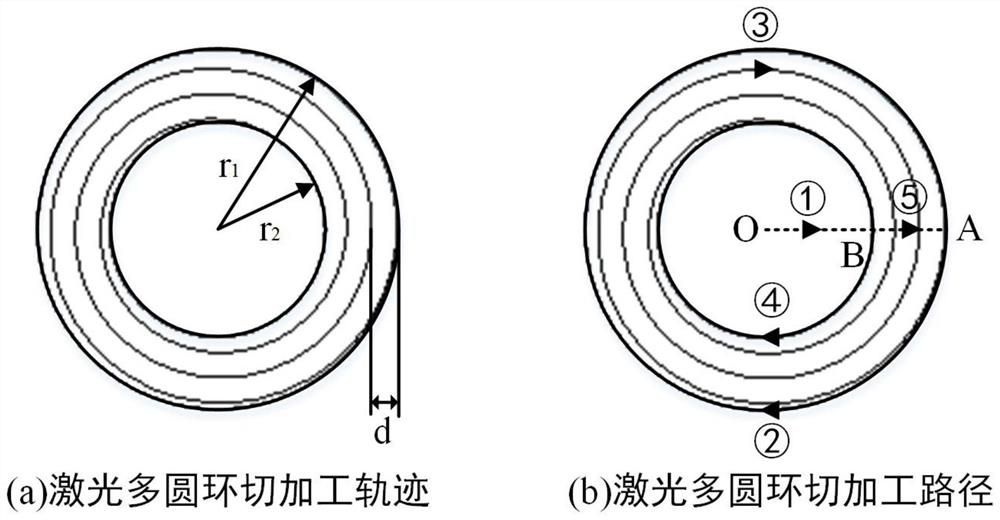

[0055] Example 2: On an alumina ceramic with a thickness of 0.38mm, pre-process a via hole with an inlet diameter of 1000 μm, and change the initial circular pattern radius r in step 6) to 1 Set to 490μm, minimum circle pattern radius r 2 It is set to 390 μm, and the filling distance d is set to 10 μm. The other steps are the same as in Example 1. The relationship between the taper of the processed hole and the processing time is as follows Figure 5 As shown by the solid line in , the hole taper basically reaches saturation when the processing time is 35s, and the saturated hole taper ratio is 5.

Embodiment 3

[0058] Example 3: On an alumina ceramic with a thickness of 0.12mm, pre-process a via hole with an inlet diameter of 1500 μm, and change the initial circular pattern radius r in step 6) to 1 Set to 740μm, minimum circle pattern radius r 2 It is set to 640 μm, and the filling distance d is set to 10 μm. The other steps are the same as in Example 1. The relationship between the taper of the processed hole and the processing time is as follows Figure 6 As shown by the solid line in , the hole taper basically reaches saturation when the processing time is 15s, and the saturated hole taper ratio is 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com