High-light-transmittance deep-freezing laser impact head and laser impact system

A laser shock, high light transmittance technology, applied in the field of cryogenic processing and laser shock, can solve the problems of low light transmittance, difficult light transmission of liquid nitrogen vaporized substances, etc., to increase laser energy, simple structure and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

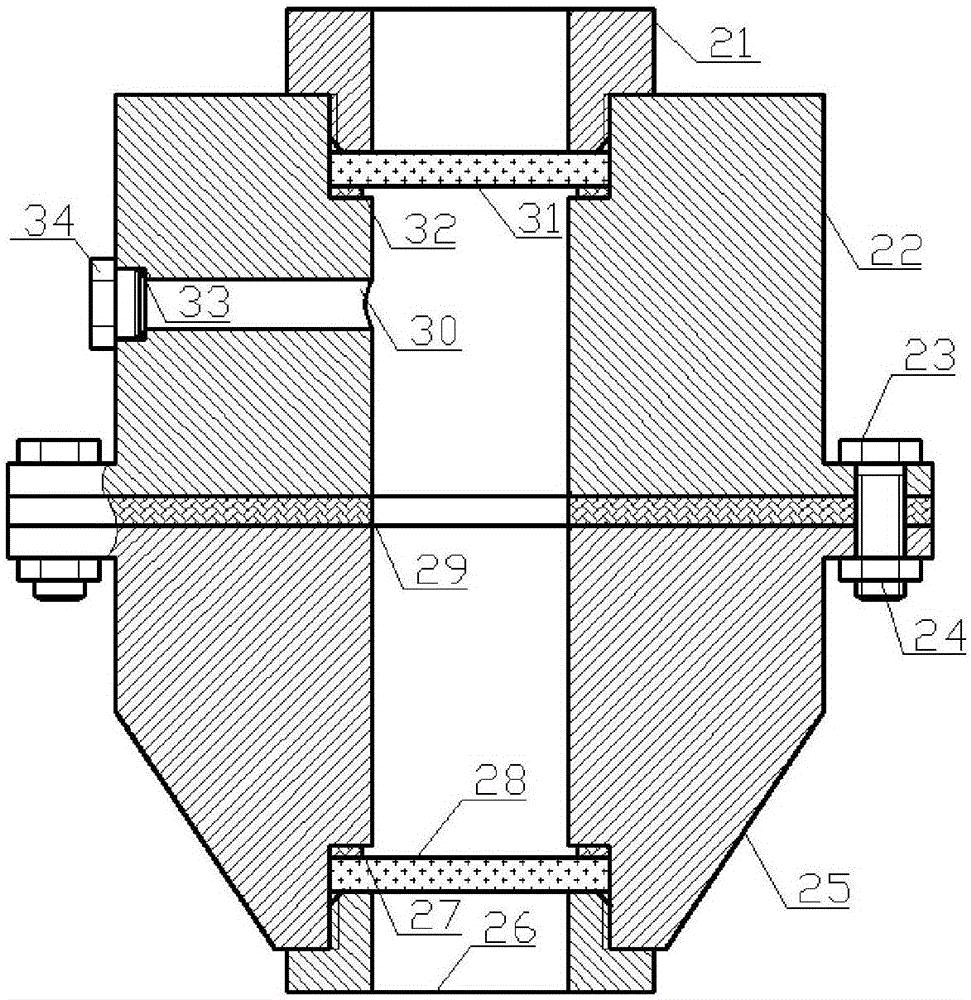

[0024] Such as Figure 1-3 shown.

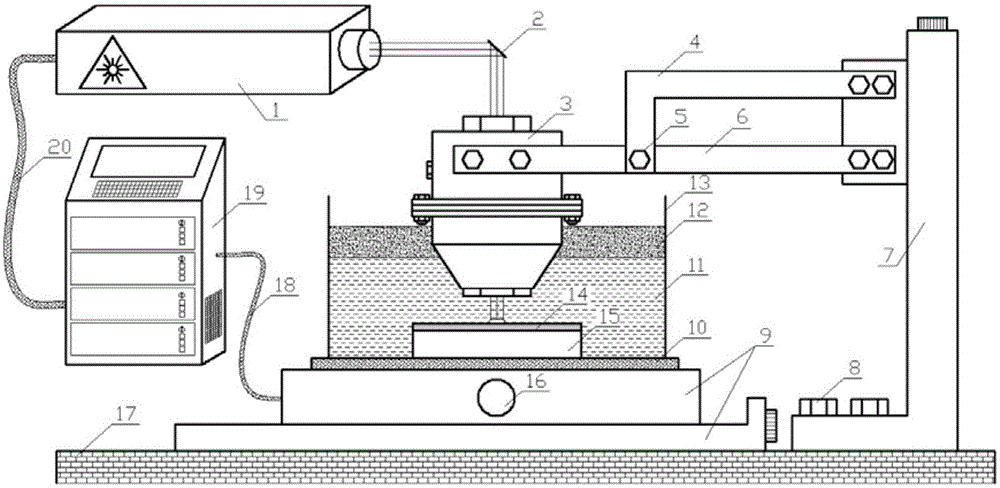

[0025] A laser shock system equipped with a high-transmittance cryogenic laser shock head, such as figure 2 As shown, the cryogenic laser impact head 3 is installed on the vertical workbench 7 through the reinforcement rib 4 and the horizontal rib 6 to ensure that the height of the impact head 3 can be adjusted; both the vertical workbench 7 and the horizontal workbench 9 use studs II8 is fixed on the assembly platform 17; the control system 19 is connected to the horizontal workbench 9 through the communication line I18, and connected to the laser 1 through the communication line II20; the workpiece 15 with the aluminum foil 14 placed on the cryogenic box 13 on the horizontal workbench 9 Among them, a heat insulating ceramic pad 10 is provided between the cryogenic box 13 and the horizontal workbench 9, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com