Light-emitting amorphous silicon carbide nanoparticle preparation method

A nanoparticle, silicon carbide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process of amorphous SiC nanoparticles, and achieve simplified preparation process and good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

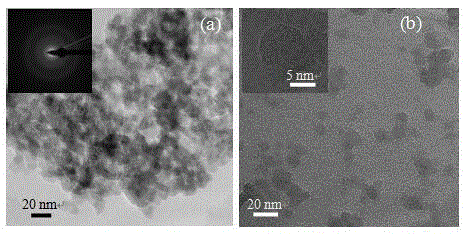

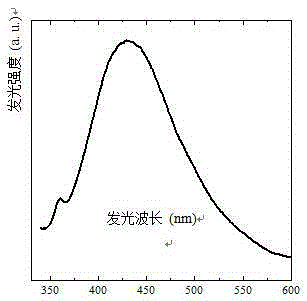

[0012] The raw material involved in the present invention is a cubic phase silicon carbide 3C-SiC polycrystalline ceramic sheet with a thickness of 2-4 mm and a diameter of more than 2.0 cm. The absolute ethanol and acetone used for cleaning are of analytical grade. The laser used is COMPexPro201 excimer pulsed laser.

[0013] Firstly, surface treatment is performed on the cubic phase silicon carbide polycrystalline ceramic sheet, and the surface of the polycrystalline ceramic sheet is polished and polished with coarse and fine sandpaper successively to make the surface of the ceramic sheet smooth. Then clean the ceramic chip to remove organic and inorganic impurities attached to its surface. The ceramic pieces are washed in absolute ethanol and acetone for 5-10 minutes in order, and then dried with a nitrogen stream. Finally, they are placed in deionized water for 5-10 minutes and dried with a nitrogen stream or a hair dryer before use. Place the prepared silicon carbide polyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com