Nitride-based light emitting diode chip and manufacturing method thereof

A light-emitting diode, gallium nitride-based technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficult to spontaneously eliminate, affect luminous efficiency, light absorption, etc., to improve the overall luminous efficiency and improve light output. Efficiency, increase the effect of side wall light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

[0026] This embodiment provides a preparation method of a gallium nitride light emitting diode chip, and the preparation steps include:

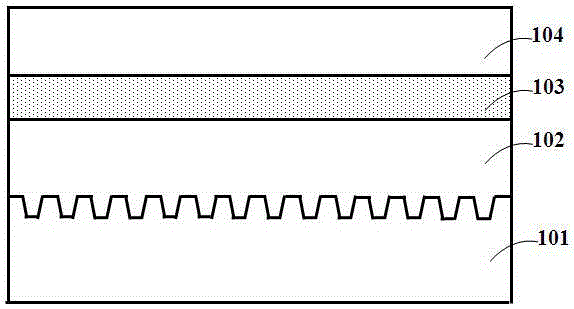

[0027] like figure 1 As shown, metal-organic chemical vapor deposition (MOCVD) is used to epitaxially grow on the patterned sapphire substrate 101 in sequence: an N-GaN layer 102 , a light-emitting layer 103 , and a P-GaN layer 104 .

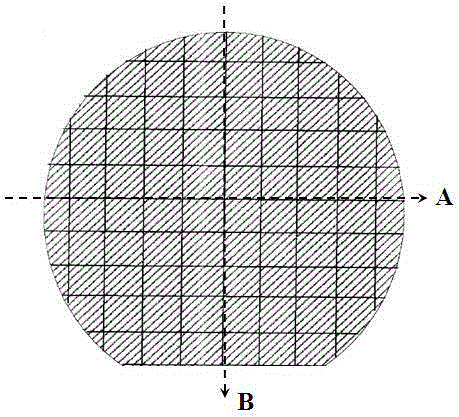

[0028] like figure 2 As shown in the figure, laser scribing is performed along the surface of the epitaxial layer, a longitudinal straight line B is formed in the direction perpendicular to the flat edge, and a transverse straight line A is formed in the direction parallel to the flat edge, and the lines A and B form a network structure. cutting path.

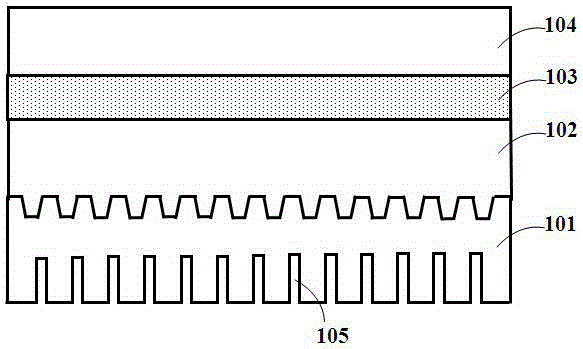

[0029] like image 3 As shown, the laser stealth cutting is used to focus at a position of 10μm~40μm inward from the back of the substrate, the laser energy is adjusted to 0.32W~0.6W, the laser frequency is adjusted to 15KHz~40KHz, an...

Example Embodiment

[0032] Example 2

[0033] like Figure 5 As shown, what is different from Embodiment 1 is that this embodiment is provided with a distributed Bragg reflection layer 108 on the backside of the substrate, so that the light extraction efficiency of the light emitting diode chip is further improved. It should be noted that the DBR 108 can be prepared before the ablation holes are obtained by laser stealth cutting inside the substrate, or can be formed after the ablation holes are obtained by laser stealth cutting inside the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com