Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

An additive manufacturing, high-energy beam technology, applied in the field of additive manufacturing, high-efficiency forming, high-energy beam additive manufacturing equipment and control fields for large-sized metal parts, to improve forming efficiency and processing quality, improve forming efficiency, The effect of avoiding distortion of the scan track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

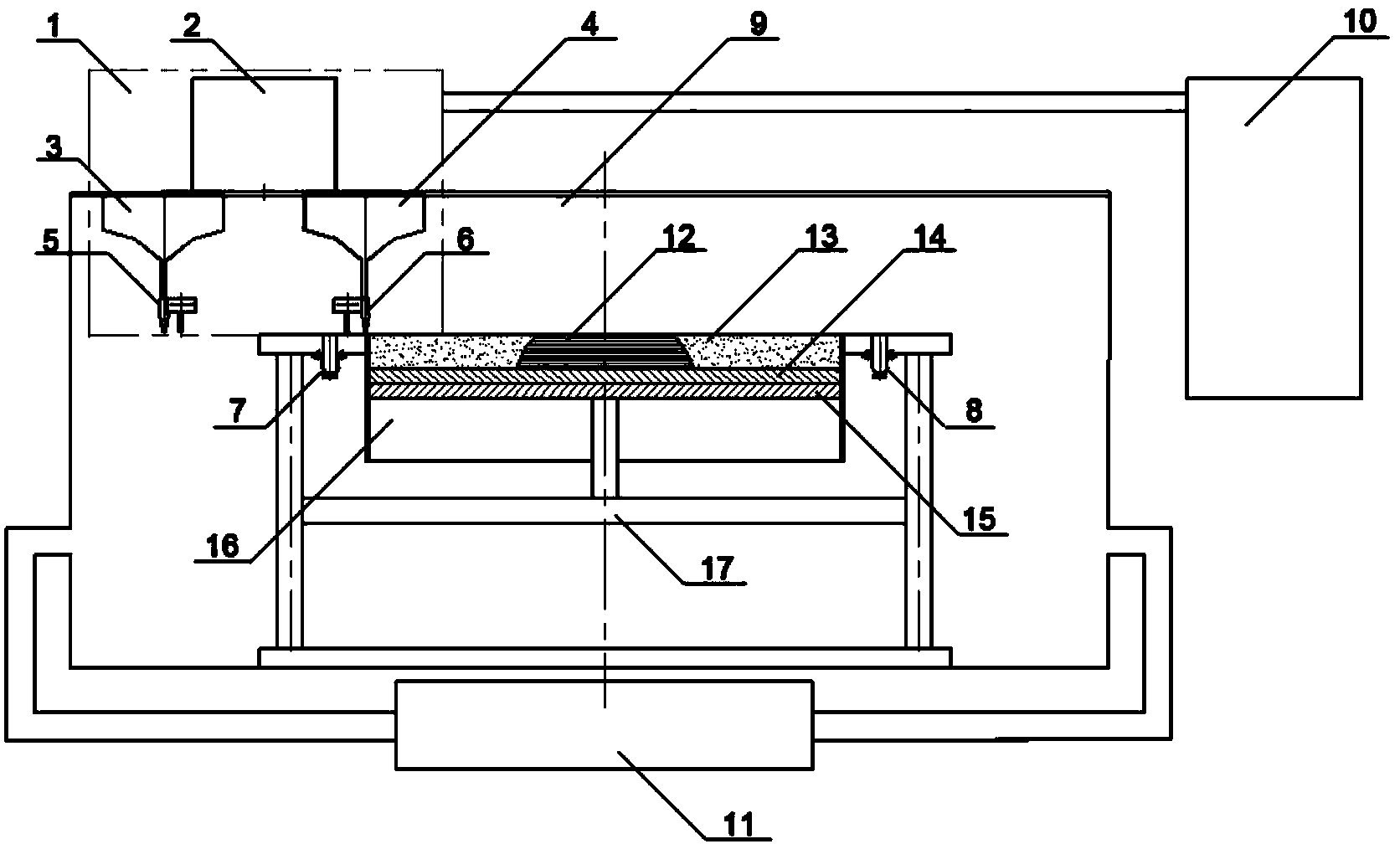

[0039] Such as figure 1 As shown, the first embodiment of the high-energy beam additive manufacturing equipment involved in the present invention includes a powder supply and scanning module 1 , a working chamber 9 , a workbench, a control system 10 and a gas purification module 11 .

[0040] The control system 10 calculates the processing trajectory and generates relevant numerical control signals, which are used to regulate the powder supply connected to the control system 10 and the cooperative work of the scanning module 1 , the workbench and the gas purification module 11 . To simplify the graph, figure 1 Only the connection between the powder supply and the scanning module 1 and the control system 10 is shown in the figure, and the connections between the other components and the control system 10 are not shown. It should be noted that this connection may include contact connections such as physical lines, or non-contact connections such as electronic signals.

[0041]...

Embodiment 2

[0056] On the basis of the first specific implementation of the high-energy beam additive manufacturing equipment involved in the present invention, the second specific implementation of the high-energy beam additive manufacturing equipment involved in the present invention can be obtained, such as Figure 4 shown. In this embodiment, the powder supply and scanning module 1 is still composed of a scanning galvanometer group 2, a first powder storage hopper 3, a second powder storage hopper 4, a first one-way powder spreader 5, and a second one-way powder spreader 6 The composition, powder supply and arrangement of components inside the scanning module 1 are also consistent with the first embodiment of the high energy beam additive manufacturing equipment. The difference is that the scanning galvanometer group 2, the first powder storage hopper 3, the second powder storage hopper 4, the first one-way powder spreader 5, and the second one-way powder spreader 6 are respectively f...

Embodiment approach

[0069] exist figure 1 On the basis of the shown equipment, the first one-way powder spreader 5 and the second one-way powder spreader 6 are removed, and a two-way powder spreader 30 is added to form the high-energy beam additive manufacturing large-scale metal parts involved in the present invention The third specific implementation of , such as Figure 5 shown.

[0070] The workbench is still composed of the first powder recovery cylinder 7 , the second powder recovery cylinder 8 and the forming cylinder 16 , and remains stationary inside the working chamber 9 . It should be noted that the "stationary" state defined here refers to the absolute stillness of the components inside the workbench along the powder spreading direction. The first powder recovery cylinder 7 and the second powder recovery cylinder 8 are still located on both sides of the forming cylinder 16 respectively. The upper surfaces of the first powder recovery cylinder 7, the second powder recovery cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com