High-energy beam-ultrasonic composite additive manufacturing method for metal materials

An additive manufacturing and metal material technology, applied in the field of metal material additive manufacturing, can solve the problems of difficulty in melting additive manufacturing, small size of parts, cracking, etc., to eliminate internal stress and internal defects, low-cost rapid manufacturing, Simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

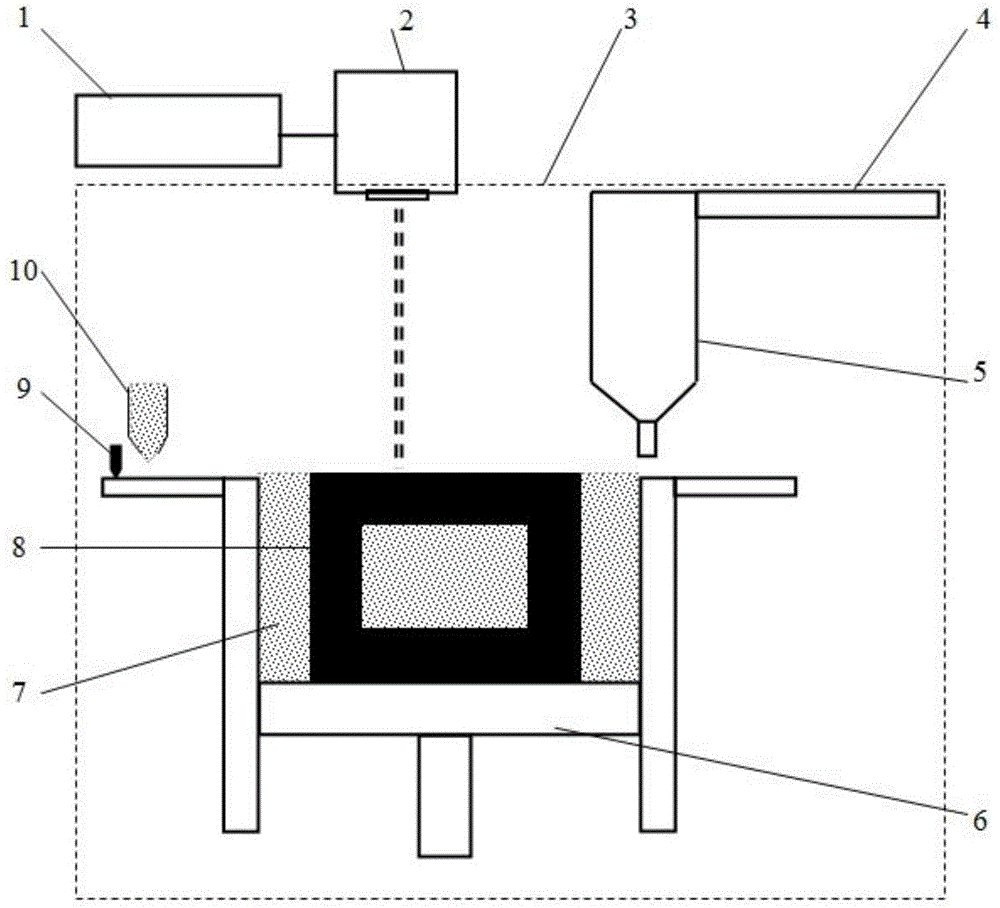

[0023] figure 1 An embodiment of the present invention is shown; a schematic diagram of a selective laser melting-ultrasonic impact composite additive manufacturing device, and the specific operation includes the following steps:

[0024] (1) The scraper 9 scrapes the metal powder 7 dropped from the powder storage box 10 onto the working plate of the forming cylinder 6 to form a pre-paved powder layer of a certain thickness;

[0025] (2) The laser 1 generates a laser beam, and selectively melts the pre-laid metal powder 7 through the scanning galvanometer 2 according to the planned cross-sectional scanning path;

[0026] (3) After the laser scanning melts / solidifies a certain number of layers, the ultrasonic impact gun 5 is driven by the mechanical device 4 to move to the working area to impact the entire surface of the solidified layer according to the set impact frequency, impact force and planned path;

[0027] (4) The ultrasonic impact gun 5 returns to the initial positio...

Embodiment 2

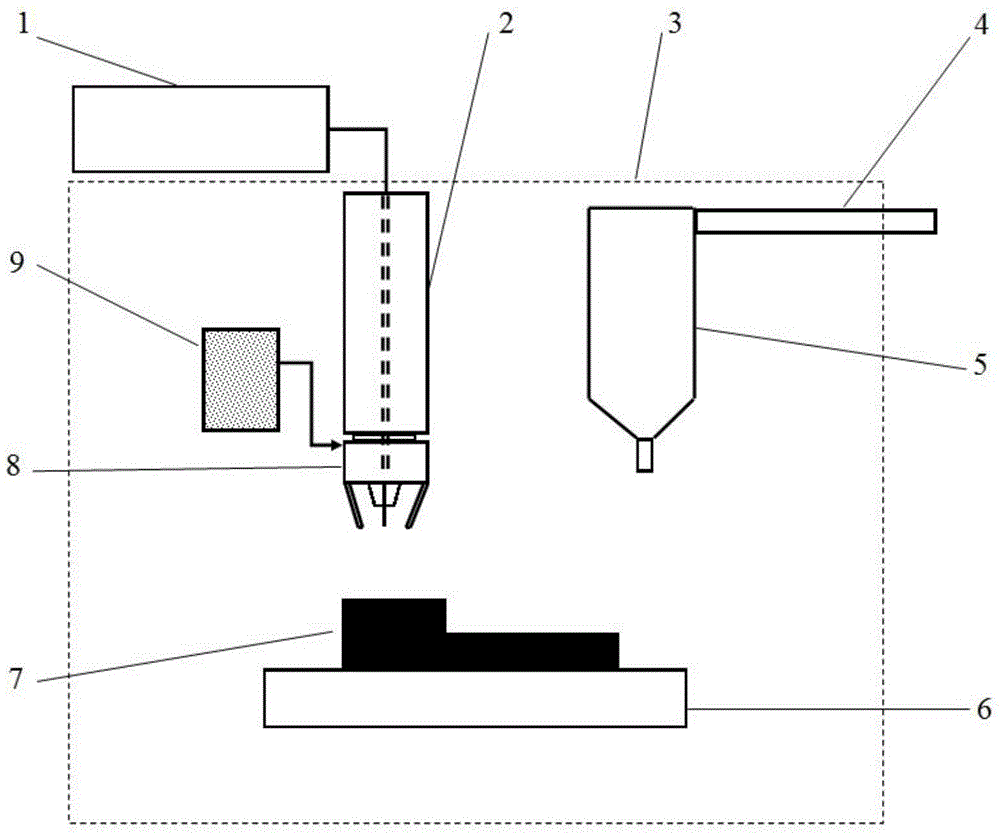

[0030] figure 2 Another specific embodiment of the present invention is shown; a schematic diagram of laser rapid prototyping-ultrasonic impact composite additive manufacturing device, and the specific operation includes the following steps:

[0031] (1) The focusing lens system 2 and the coaxial nozzle 8 are moved to the working area above the substrate 6;

[0032] (2) The laser 1 generates a laser beam with a certain spot diameter through the focusing lens system 2 to melt the substrate 6 or the surface of the formed layer 7 to form a molten pool. At the same time, the powder feeder 9 uses the protective gas to transport the metal powder, and sprays the metal powder into the molten pool through the coaxial nozzle 8, thereby melting / solidifying to form a solidified layer;

[0033] (3) After the laser melts / solidifies a certain number of layers according to the planned scanning path, the focusing lens system 2 and the coaxial nozzle 8 return to the initial position, and incr...

Embodiment 3

[0038] This embodiment has the same characteristics as Embodiment 1 except the following: the laser 1 is an electron beam emitting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com