Charged particle beam apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

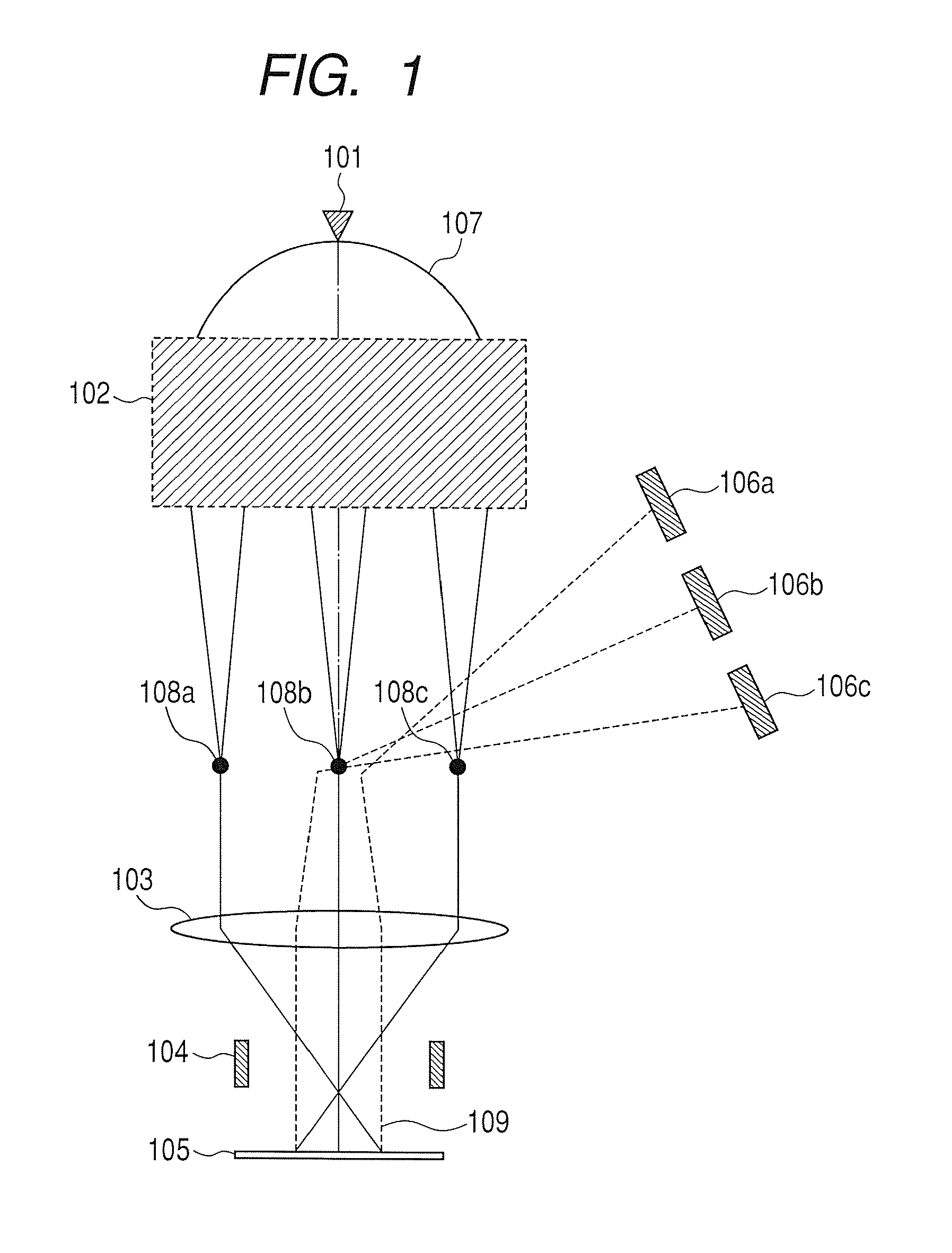

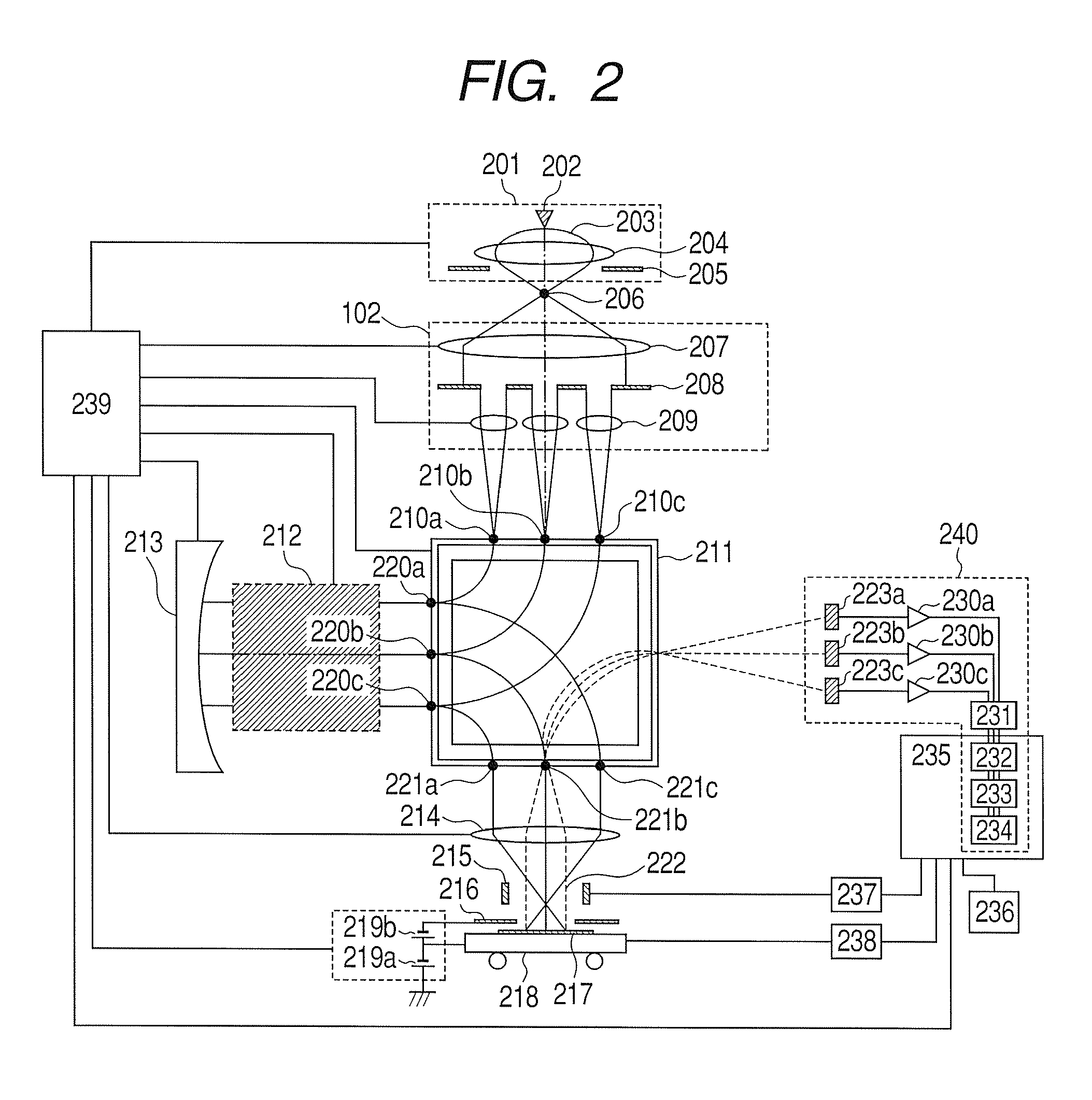

[0033]FIG. 2 is a view showing a schematic configuration of a multi-beam type electron beam inspection apparatus according to the first embodiment of the invention.

[0034]First, a makeup of the apparatus is described hereinafter. An electron gun 201 is comprised of a cathode 202 made of material low in work function, an anode 205 higher in potential than the cathode 202, and an electromagnetic lens 204 for superimposing a magnetic field on an accelerating electric field formed between the cathode and the anode. With the present embodiment, use is made of a Schottky type anode capable of easily obtaining large current, and stable in electron emission. A multi-beams forming unit 102, and a beam separator 211 are disposed in a direction downstream from the electron gun 201, in which a primary beam 203 is pulled out of the electron gun 201. Herein, with the present embodiment, the multi-beams forming unit 102 is comprised of a collimator lens 207, an aperture array 208 wherein plural ape...

second embodiment

[0058]With the first embodiment of the invention, the off-axial aberration corrector shown in FIG. 3 has the configuration wherein the electrostatic mirror is disposed at the position of the symmetry plane 307b. In contrast, with a second embodiment of the invention, there is adopted a configuration wherein an electrostatic mirror is disposed at the respective positions of the symmetry planes 307b, and 307c of the off-axial aberration corrector shown in FIG. 3, thereby disposing a combination of the aberration corrector, and the electrostatic mirror at two locations.

[0059]FIG. 6 is a schematic view of a multi-beam type electron beam inspection apparatus according to the second embodiment of the invention. In FIG. 6, placement of constituent elements including an electron gun 201, a cathode 202, an anode 205, an electromagnetic lens 204, a collimator lens 207, an aperture array 208, and a lens array 209 is turned clockwise through 90 degrees from placement of like constituent element...

third embodiment

[0075]With the first embodiment, since the position of the electrostatic octupole field strength 303h in the aberration corrector, shown in FIG. 3, coincides with the position of the electrostatic mirror 213, an electrostatic octupole field strength corresponding to the electrostatic octupole field strength 303h is not disposed. In contrast, with the second embodiment, there is shown the method for superimposing the electrostatic mirror field on the multipole fields by devising a novel configuration for the electrostatic mirror 602a although the respective positions of the electrostatic quadrupole field strength 302d, and the electrostatic octupole field strength 303d, in the off-axial aberration corrector shown in FIG. 3, coincide with the position of the electrostatic mirror 602a. Accordingly, with the present embodiment, there is shown a method for superimposing the electrostatic octupole field strength 303h on the electrostatic mirror 213 in the configuration of the apparatus ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com