Energy-shielding plastics film

一种塑料膜、透明塑料膜的技术,应用在磁场/电场屏蔽、薄料处理、金属材料涂层工艺等方向,能够解决温度上升、玻璃破损、局部温度升高等问题,达到稳定性长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The plastic film 1 of the present invention was produced in the following manner. The film consists in the following order: a transparent carrier layer, on one side a hardcoat protective layer, on the other side first a first metal layer, then a silver-containing layer, then a third metal layer, on the other side It is topped with an adhesive layer or adhesive, on top of which is another embedded layer, followed by a second adhesive layer.

[0079] The fabrication starts with the application of a metal layer onto a plastic carrier layer using DC magnetron sputter deposition. The plastic carrier layer is made of polyethylene terephthalate (PET) and has a thickness of about 23 μm. The metal concentrations indicated below are expressed in weight units and relate to the weight of the entire film, without the optional release layer.

[0080] The applied first metal sublayer contained chromium (0.8 ppm), zinc (1.5 ppm), nickel (9.3 ppm) and indium antimonide (5.05 ppm). Th...

Embodiment 2

[0089] A window with double glazing is coated on the inside with about half of its surface with the plastic film 1 from example 1. The temperature of the inner surface is measured with an infrared camera. Where the film was applied, the measured temperature was about 23.4°C, while the glass surface without the film had a temperature of about 18.6°C on its surface. This experiment demonstrates the effectiveness of the film for reflecting long-wavelength thermal radiation, and thus for thermal insulation.

Embodiment 3

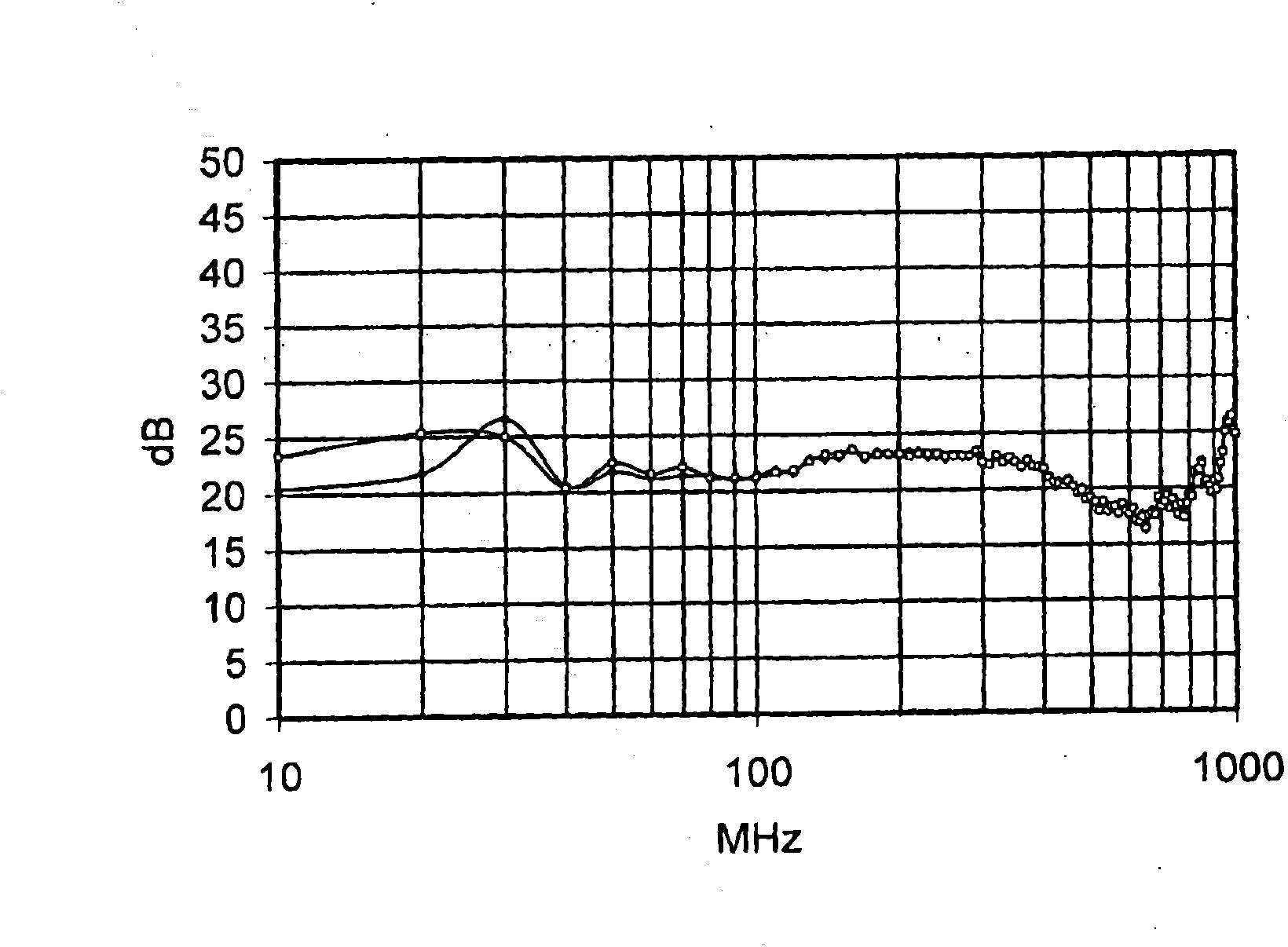

[0091] The two glass surfaces were provided with plastic films 2 and 3 in Example 1, respectively. These glass surfaces were tested for shielding effectiveness (SE) against electromagnetic radiation in the frequency range from 10 MHz to 1 GHz using a TEM-t unit according to ASTM D4935. The results of this assay allow prediction of the behavior of these films under IEEE299 or other standard conditions.

[0092] The results are shown in figure 1 middle. A SE or damping coefficient of at least 20dB was measured for the main part of the test frequency range. The SE rises above 25dB at frequencies of 20-30MHz, and even at 120-170MHz. Only at frequencies between 180 and 700 MHz, a slightly reduced SE was measured, however still at least 17 dB. The average damping value over the entire frequency range is equal to 22dB. If it is realized that 20dB of damping results in a 90% reduction of the electromagnetic field strength and a 99% reduction of the remaining electromagnetic capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com