Chemical corrosion liquid in high selection ratio of gallium arsenide in aluminum arsenide / gallium arsenide

A high selectivity, chemical etching technology, applied in the field of chemical etching solution, can solve the problems of device damage, low selectivity ratio, damage to photoresist by etching solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

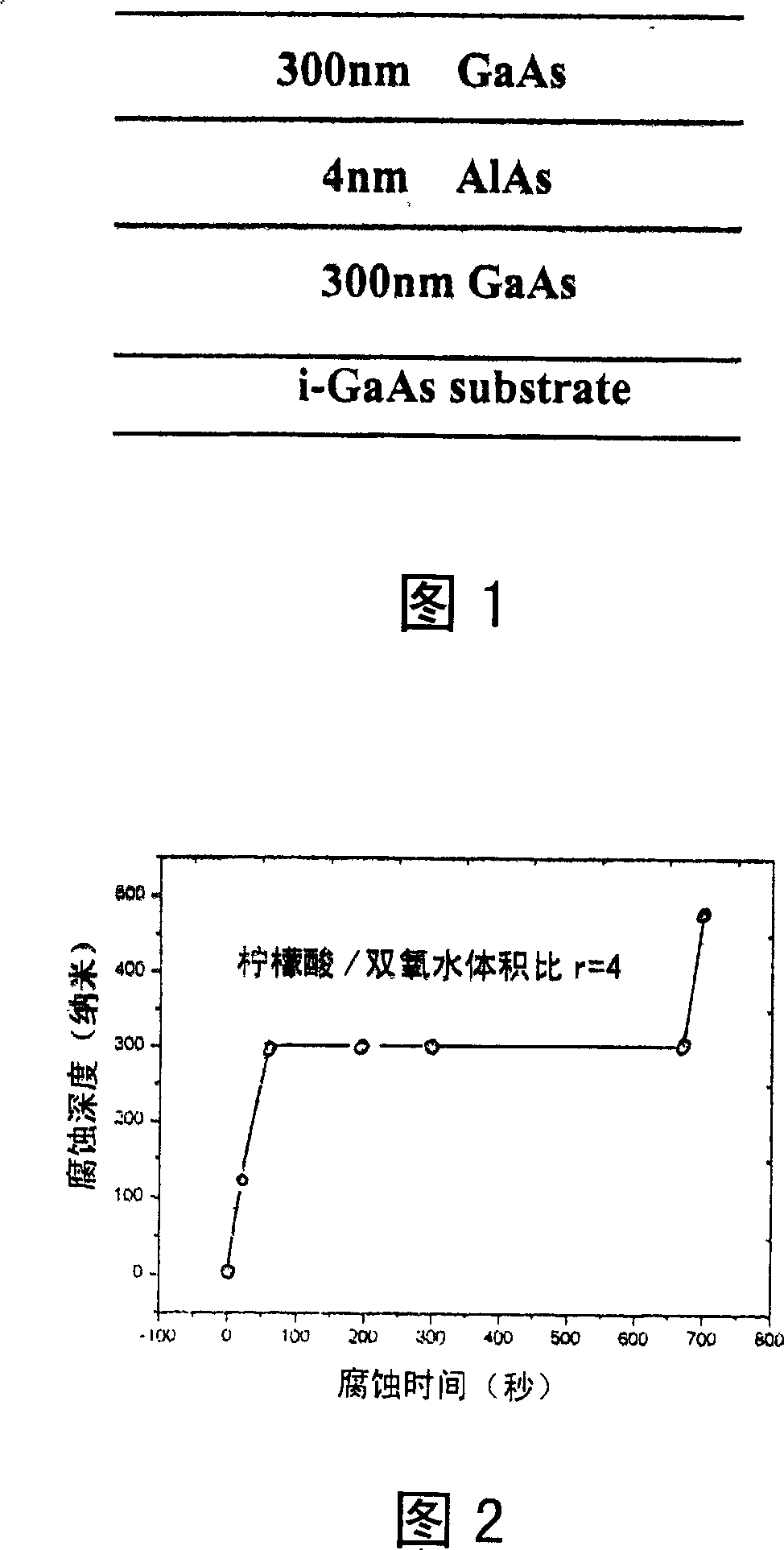

[0021] A kind of GaAs high selectivity ratio chemical corrosion solution to AlAs / GaAs of the present invention is characterized in that, comprises:

[0022] Citric acid solution and hydrogen peroxide, the volume ratio of the citric acid solution and hydrogen peroxide is 4:1.

[0023] Wherein the citric acid solution is formed by mixing the ratio of 1 gram of solid citric acid and 1 ml of water.

[0024] Wherein the concentration of hydrogen peroxide is 30%.

[0025] The using method of the present invention is:

[0026] Using citric acid solution: H 2 o 2 The method for selectively etching the GaAs layer from the AlAs layer with a solution with a volume ratio of 4:1. This method not only has a high selective etching ratio, but also is compatible with GaAs integrated circuit technology, and has the characteristics of simple technology, safety and stability, simple operation and good repeatability.

[0027] The present invention adopts citric acid solution: H 2 o 2 The vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com