Wet etching method for gallium arsenide/aluminum arsenide distributed Bragg reflector

A Bragg reflector and wet etching technology, applied in semiconductor/solid-state device manufacturing, lasers, electrical components, etc., can solve the problems of serious heating of P-type DBR, large series resistance, affecting device lasing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

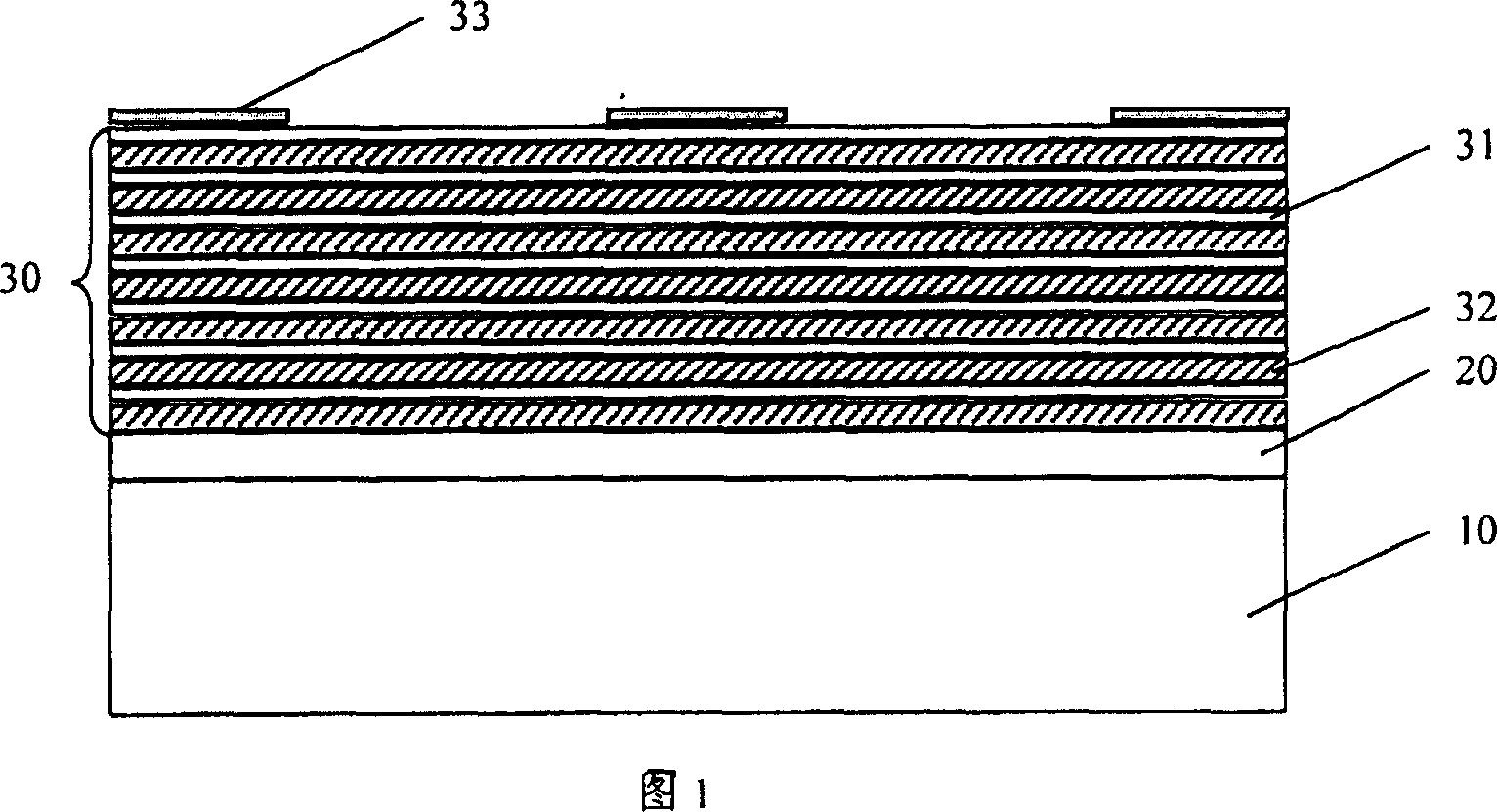

[0024] See also shown in Fig. 1, a kind of wet etching method of gallium arsenide / aluminum arsenide distributed Bragg reflector of the present invention is characterized in that, comprises the following steps:

[0025] (A) On the substrate 10, a gallium arsenide buffer layer 20 is epitaxially grown by molecular beam epitaxy, the substrate 10 is semi-insulating gallium arsenide, and the thickness of the gallium arsenide buffer layer 20 is 200 nm;

[0026] (B) growing a plurality of periodically distributed Bragg reflectors 30 on the gallium arsenide buffer layer 20, wherein the plurality of periodically distributed Bragg reflectors 30 include: a gallium arsenide layer 31 and aluminum arsenide grown on the gallium arsenide layer 31 Layer 32, wherein the period number of the multiple periodically distributed Bragg reflectors 30 is 7, the thickness of the gallium arsenide layer 31 is 70nm, and the thickness of the aluminum arsenide layer 32 is 158nm;

[0027] (C) Photolithography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com