Lift off method

An optical device and epitaxial substrate technology, applied in the lift-off field, can solve the problems of uneven damage to the buffer layer, inability to properly peel off the epitaxial substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

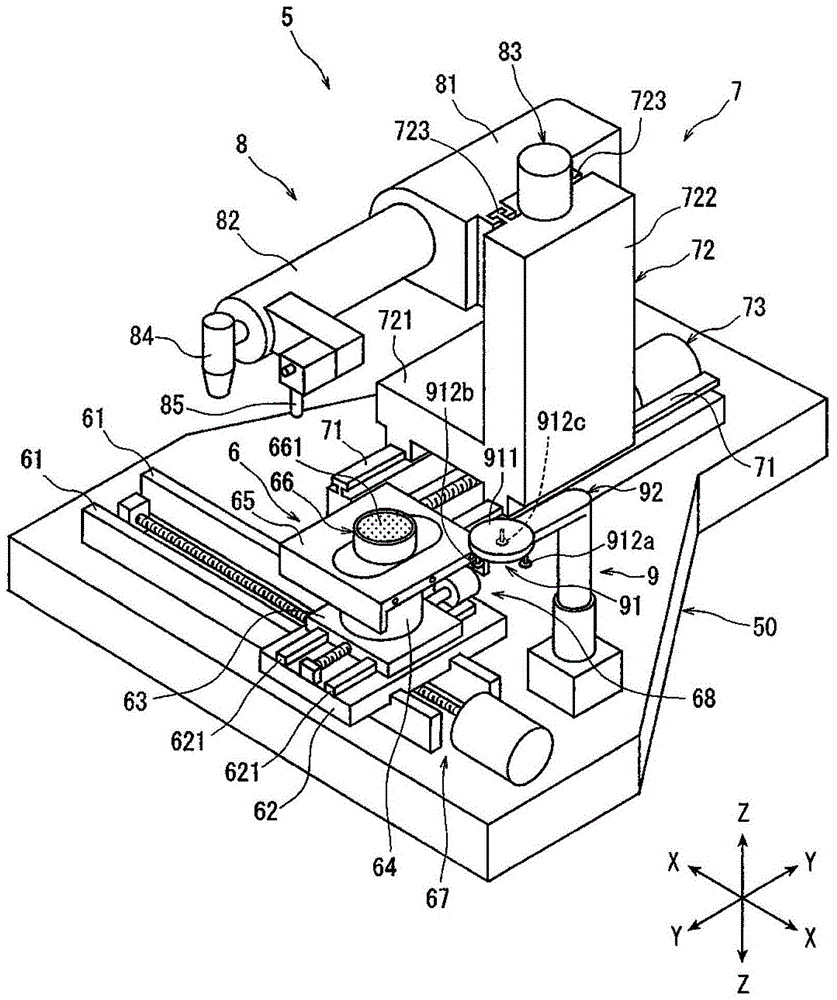

[0049] Hereinafter, preferred embodiments of the lift-off method according to the present invention will be described in detail with reference to the drawings.

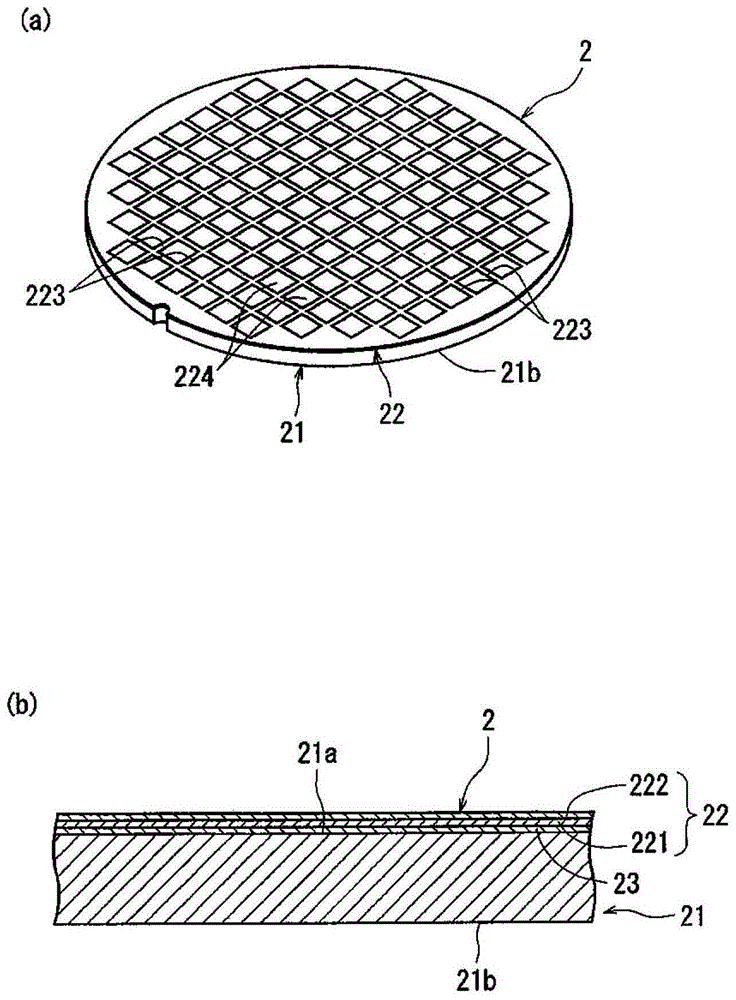

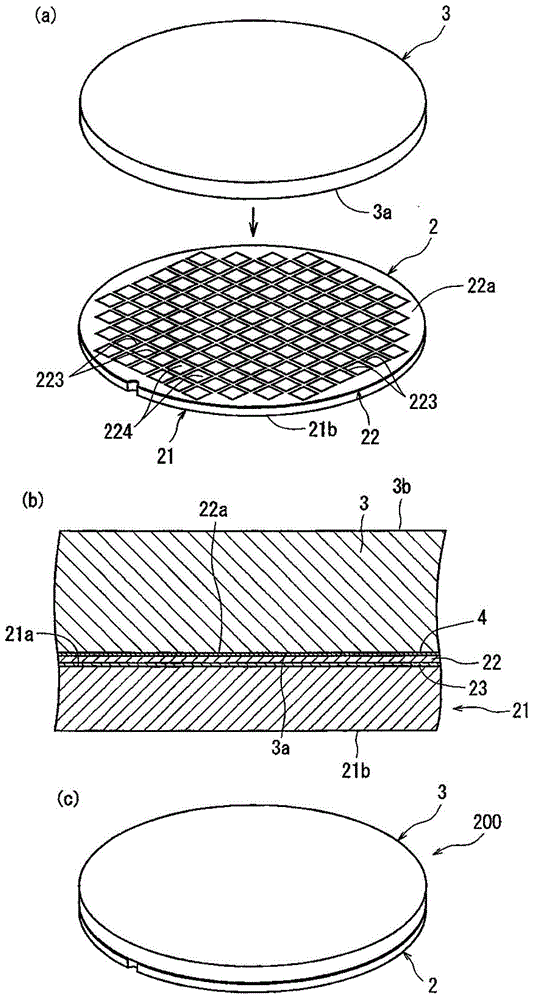

[0050] figure 1 (a) and (b) show a perspective view and an enlarged sectional view of main parts of an optical device wafer on which an optical device layer transferred to a transfer substrate by the lift-off method of the present invention is formed.

[0051] figure 1 In the optical device wafer 2 shown in (a) and (b), an optical device composed of an n-type gallium nitride semiconductor layer 221 and a p-type gallium nitride semiconductor layer 222 is formed on the surface 21a of the epitaxial substrate 21 by the epitaxial growth method. The device layer 22, wherein the epitaxial substrate 21 is composed of a disc-shaped sapphire substrate with a diameter of 50 mm and a thickness of 600 μm. In addition, when the optical device layer 22 composed of the n-type gallium nitride semiconductor layer 221 and the p-type g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com