Method for stripping metal film by using positive photoresist as mask

A metal film, positive adhesive technology, applied in the field of semiconductor chip processing, can solve the problems of increased process, unsuitable for mass production of chips, expensive and other problems, and achieves the effect of high verticality, optimized peeling effect, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

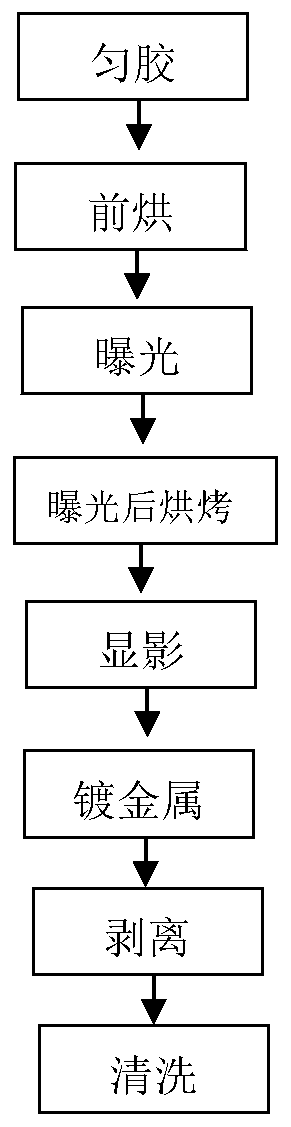

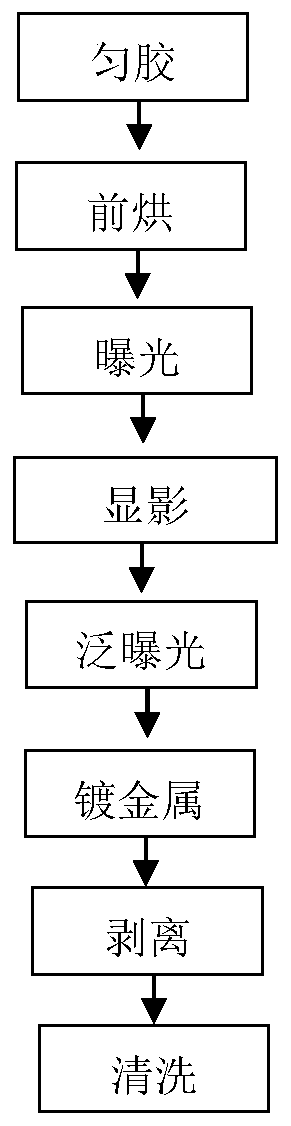

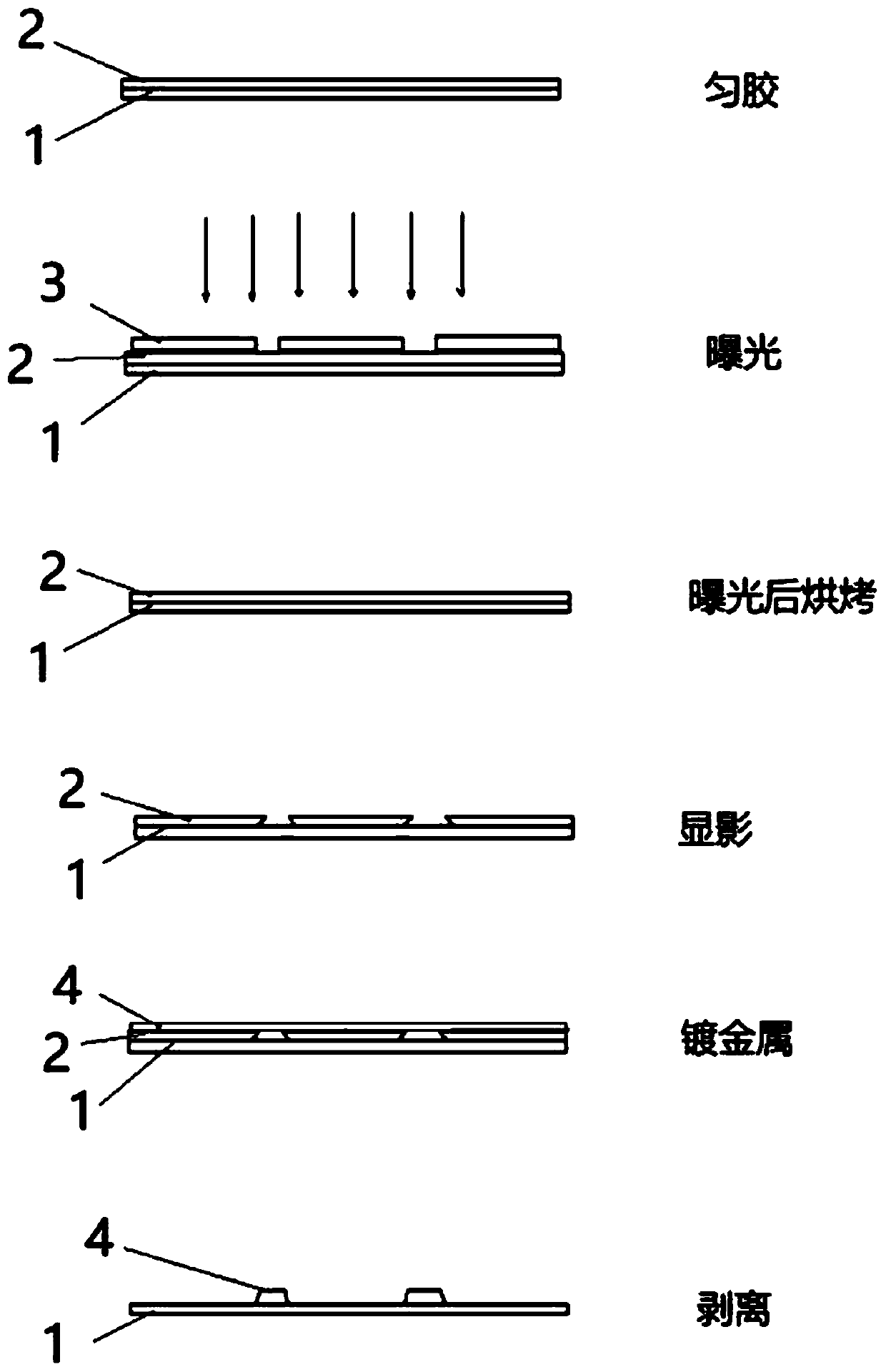

[0024] The method for stripping the metal film from the positive glue, the steps include:

[0025] (1) Apply the positive glue 2 evenly on the surface of the substrate 1 using a glue applicator and pre-baked, the speed of glue spreading: 5500 rpm, the thickness of the glue: 1.8 microns, and the front baking: 110 degrees Celsius for 180 seconds;

[0026] (2) Place the photoresist plate 3 on the positive resist 2, and use a photolithography machine to expose, the exposure energy: 20 mW / cm2 for 3.5 seconds;

[0027] (3) developing with developing solution, developing time: 35 seconds;

[0028] (4) Use a photolithography machine for pan exposure, pan exposure energy: 20 mW / cm2 for 3.5 seconds;

[0029] (5) Use an evaporation station or a sputtering station for metal coating; vapor-deposit titanium, platinum and gold three layers of metal, thickness: 10nm, 50nm, 100nm.

[0030] (6) Use the blue film to tear off the metal film with glue on the bottom;

[0031] (7) Soak in acetone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com