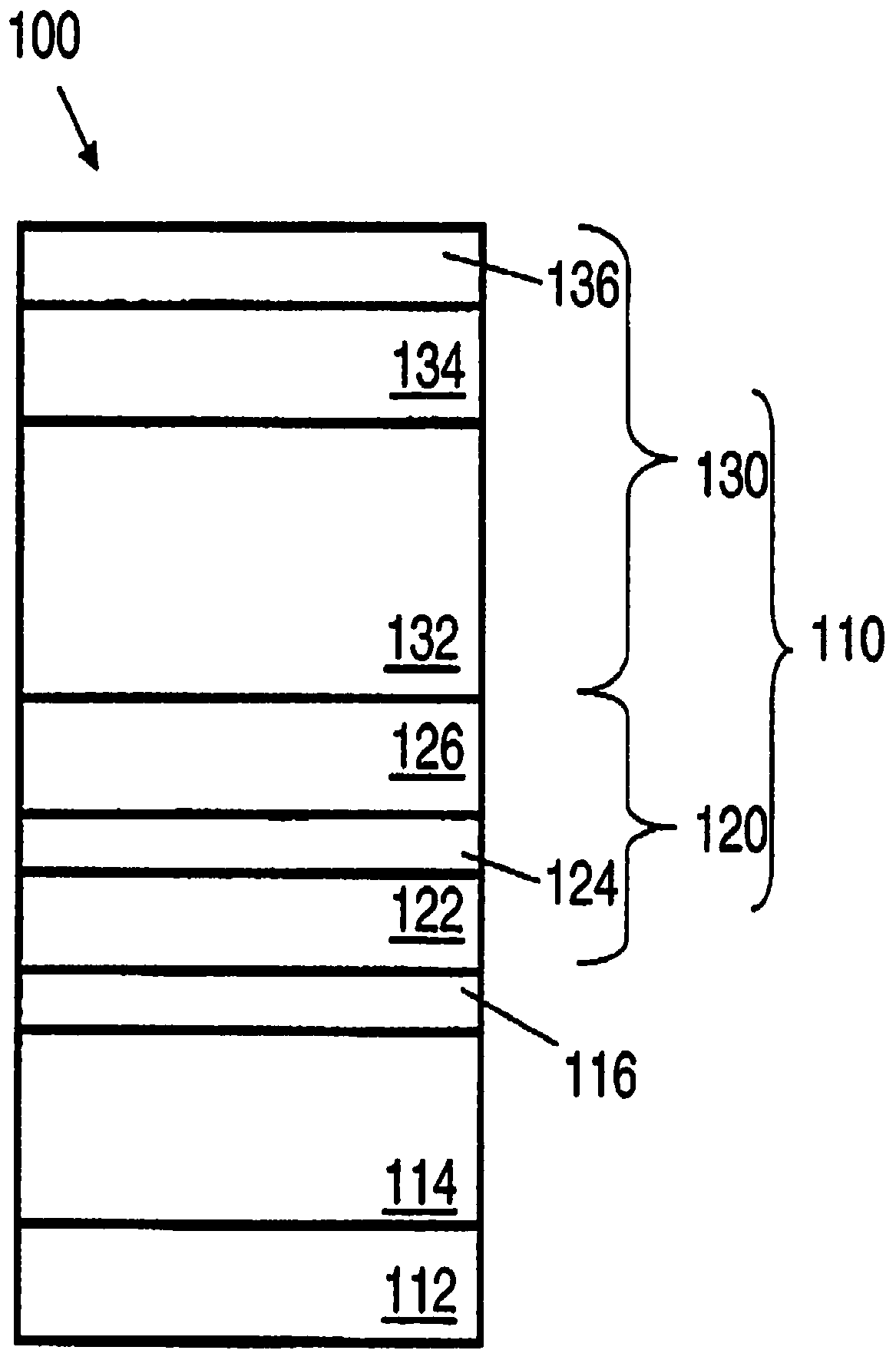

High growth rate deposition for group iii/v materials

A technology of deposition temperature and deposition rate, which is applied in the field of epitaxial growth of III/V materials, which can solve the problems of reducing the quality of epitaxial materials and increasing the deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

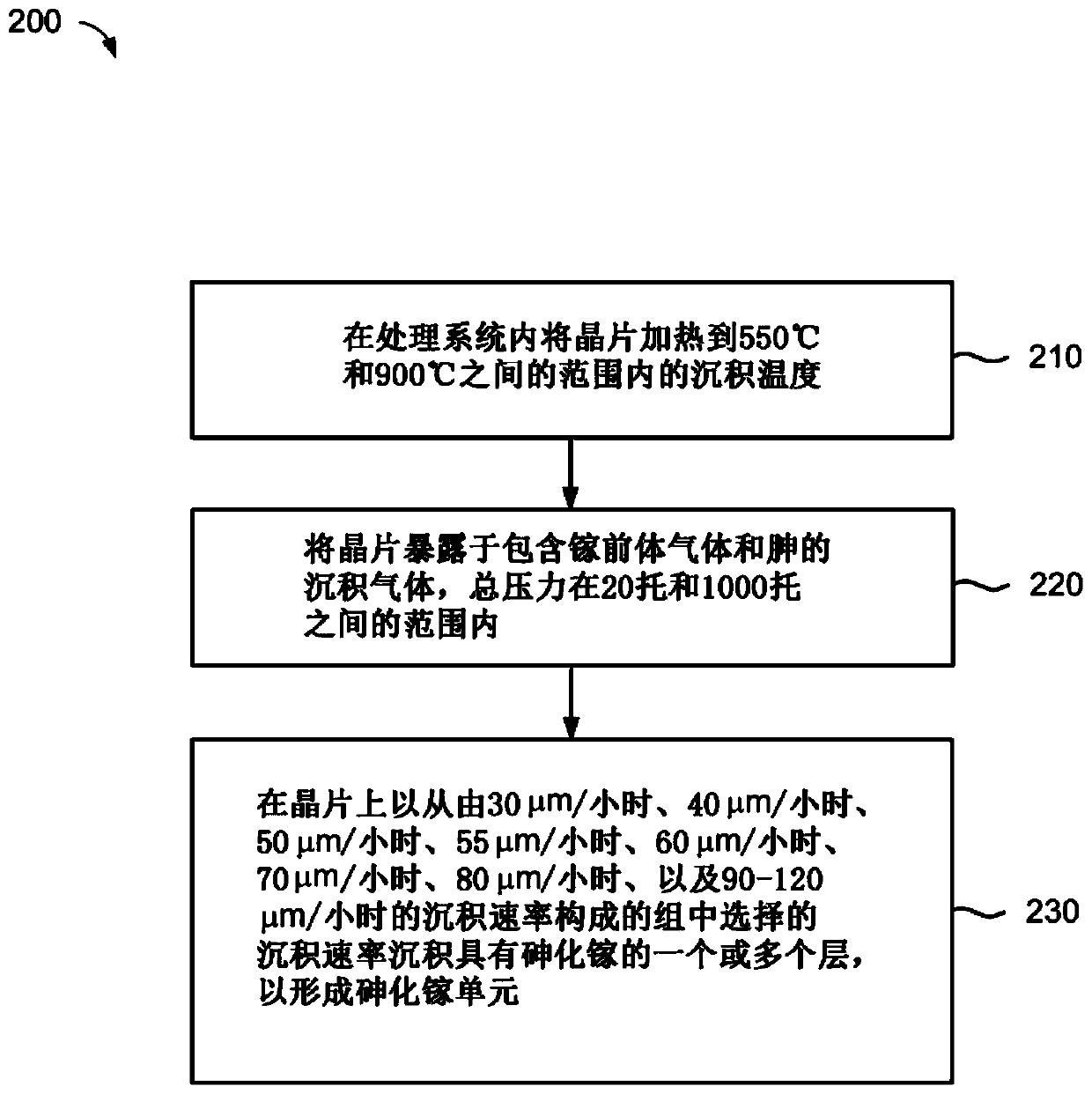

[0045] Example 1 - GaAs: In one example, a deposition gas can be formed by combining a gallium precursor (eg, TMG) and an arsenic precursor (eg, arsine). The substrate can be heated to deposition temperature and exposed to deposition gases. The deposition temperature can have a wide range. In one example, the deposition temperature may range from about 600°C to about 800°C, such as from about 650°C to about 750°C or from about 650°C to about 720°C. In one example, the deposition gas may contain about 2000 cc of hydrogen (H 2 ) about 100cc of arsine and about 200cc of TMG / H 2 mixture (in H 2 about 10% of TMG). The group III / V material comprises gallium and arsenic and can be deposited at a rate of about 30 μm / hour or higher, such as about 40 μm / hour or higher, preferably about 50 μm / hour or higher, preferably about 55 μm / hour or higher, And more preferably, about 60 μm / hour or higher. In one example, a deposition rate greater than about 60 μm / hour may include a depositi...

Embodiment 2

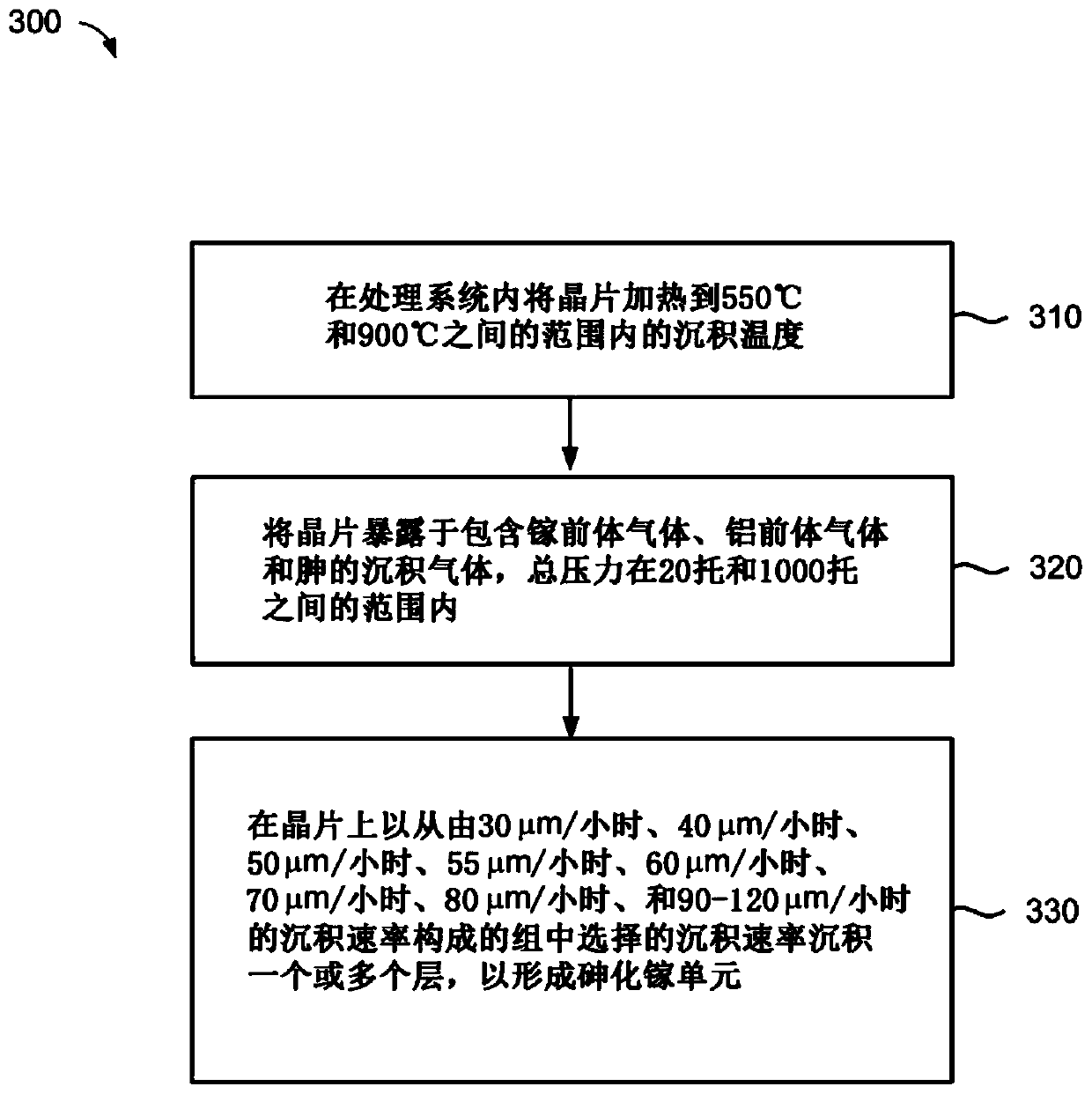

[0046] Example 2 - GaAlAs: In another example, a deposition gas may be formed by combining a gallium precursor (eg, TMG), an aluminum precursor (eg, TMA), and an arsenic precursor (eg, arsine). The substrate can be heated to deposition temperature and exposed to deposition gases. The deposition temperature can have a wide range. In one example, the deposition temperature may range from about 600°C to about 800°C. In one example, the deposition gas may contain: about 100 cc of arsine in about 2000 cc of hydrogen; about 200 cc of TMG / H 2 mixture (in H 2 about 10% of TMG); and about 200cc of TMA / H 2 (at H 2 in about 1% of TMA). Group III / V materials comprise gallium, aluminum and arsenic and can be deposited at a rate of about 30 μm / hour or higher, such as about 40 μm / hour or higher, preferably about 50 μm / hour or higher, preferably about 55 μm / hour or more High, more preferably, about 60 μm / hour or higher. In one example, a deposition rate greater than about 60 μm / hour ma...

Embodiment 3

[0047] Example 3 - AlGaInP: In another example, the deposition gas can be obtained by combining a gallium precursor (eg, TMG), an aluminum precursor (eg, TMA), an indium precursor (eg, trimethylindium-TMI), and phosphorous Precursors (e.g., phosphine-PH 3 ) to form. The substrate can be heated to deposition temperature and exposed to deposition gases. The deposition temperature can have a wide range. In one example, the deposition temperature may range from about 600°C to about 800°C. In one example, the deposition gas may contain: about 200 cc of TMG / H 2 mixture (in H 2 About 10% of TMG in the middle); about 200cc of TMA / H 2 (at H 2 about 1% TMA in the medium); about 200cc of TMI / H 2 (at H 2 about 1% TMI in about 2000 cc of hydrogen); and about 100 cc of phosphine in about 2000 cc of hydrogen. Group III / V materials comprise gallium, aluminum, indium and phosphorus and can be deposited at a rate of about 30 μm / hour or higher, such as about 40 μm / hour or higher, prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com