Method for manufacturing isolation structure of semiconductor device and semiconductor device thereof

A device isolation and semiconductor technology, applied in semiconductor lasers, laser components, instruments, etc., can solve problems such as inability to complete lift-off operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a semiconductor device, which is manufactured by the following method:

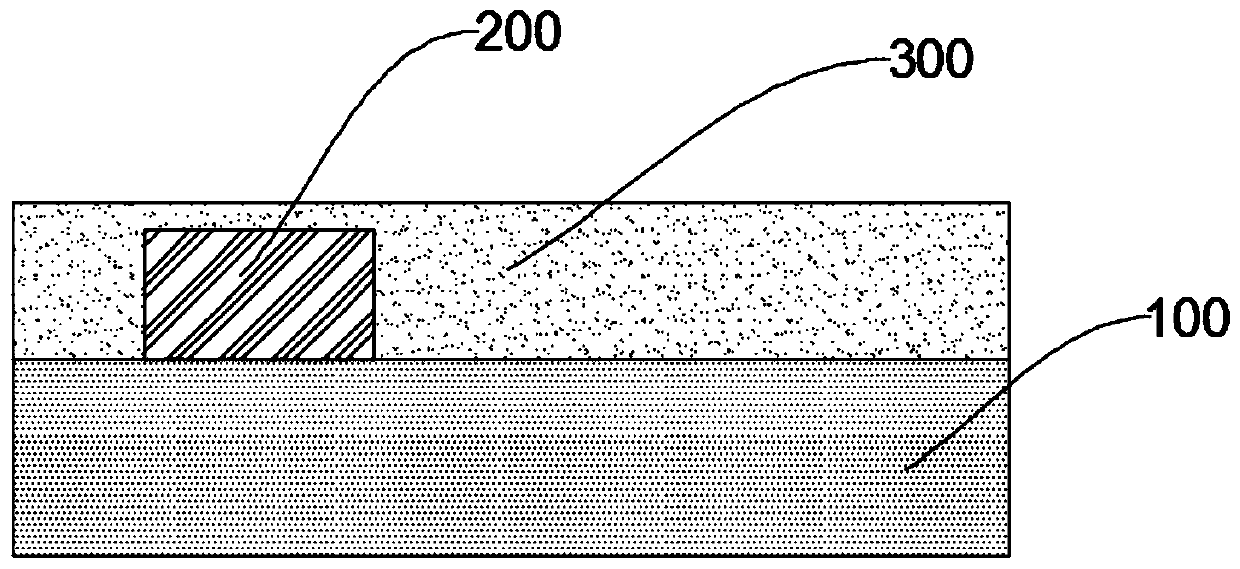

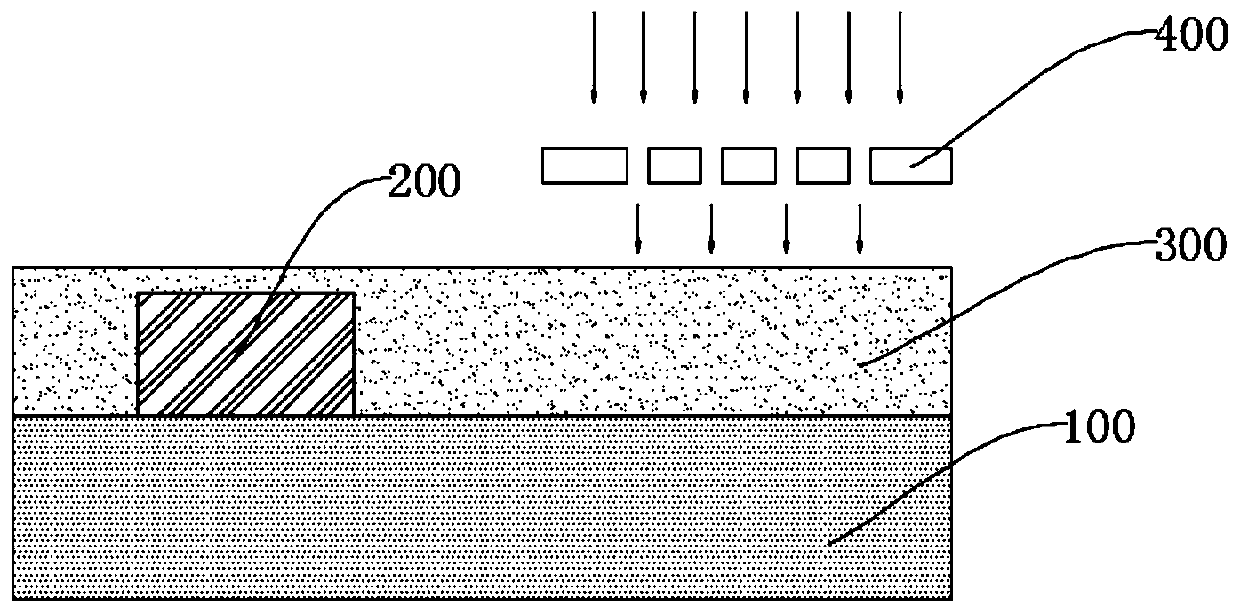

[0038] (1) providing a substrate 100;

[0039] (2) forming the device 200 on the substrate 100;

[0040] (3) Forming a conductive isolation structure 700 on the substrate 100 .

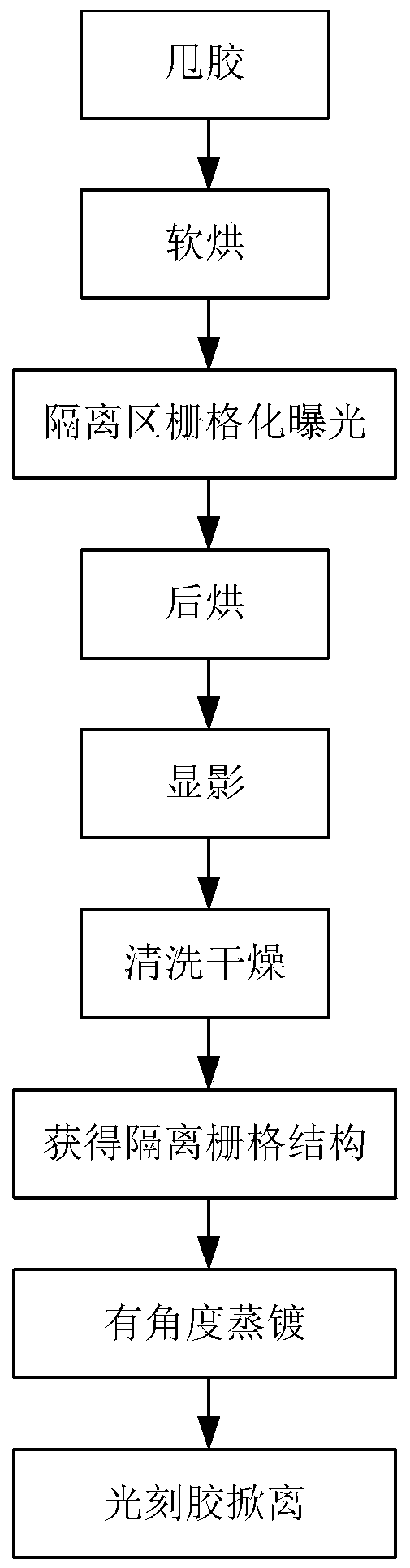

[0041] according to figure 1 As shown, the method wherein the conductive isolation structure 700 is formed includes the following steps:

[0042] (1) Forming the photoresist layer 300 on the device 200 and the substrate 100 , the method for forming the photoresist layer 300 includes performing photoresist spinning on the upper surfaces of the device 200 and the substrate 100 after etching. In this embodiment, the photoresist is a negative photoresist, the model is Su-8 3005 from MicroChem, the thickness of the formed photoresist layer 300 is 7 μm, and the speed of spinning the photoresist is 2000 rpm.

[0043] (2) Baking the photoresist layer 300 after the spun-off is performed to remove the so...

Embodiment 2

[0054] The difference from Embodiment 1 is that in the manufacturing method of the semiconductor device provided in this embodiment, the substrate 100 and the device 200 are exposed to the photoresist layer 300 without masking after removing the photoresist layer 300. Thus, the first structure 500 is formed in the photoresist layer 300 .

[0055] The photoresist in this embodiment is a negative photoresist, and the exposure treatment adopted is exposure treatment using interference light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com