Method for laser stripping mobile metal products and equipment for implementing the method

A metal and product technology, applied in the field of oxide layers, can solve the problems of not being able to obtain the best and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

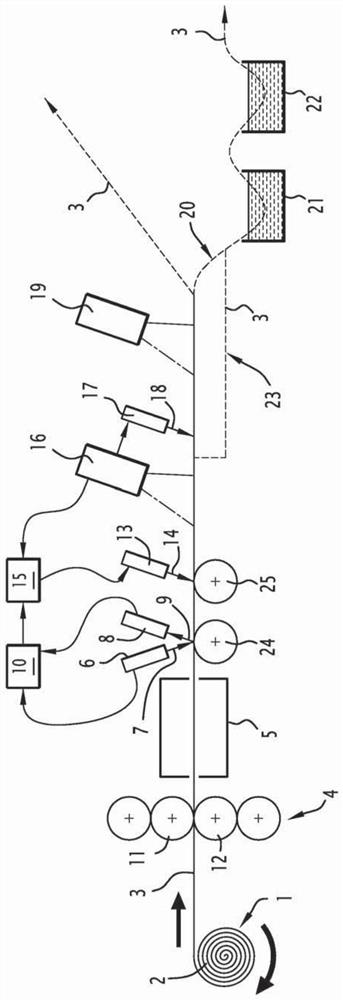

[0054]The laser descaling equipment, which will be described and illustrated in detail by way of example, will involve processing a moving cold-rolled stainless steel strip that has just been cold-rolled and annealed on a continuous line, and performs at least most of the descaling function according to the present invention Functional laser descaling equipment is also included in the continuous line to replace the electrolytic pickling equipment and / or chemical pickling equipment usually used on this type of continuous line (examples of this type of continuous line can especially It is found in documents EP 0509 177-A2 and EP 0 695 808-A1).

[0055]Of course, the laser descaling device according to the present invention to be described can also be incorporated into a continuous processing line that includes a greater or lesser number of devices than the continuous processing line to be described, or it can be subjected to special use for such descaling. Of separation equipment.

[0056]I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com