Array base board structure of thin film transistor liquid crystal display and its producing method

An array substrate structure and thin-film transistor technology, which is applied in semiconductor/solid-state device manufacturing, transistors, static indicators, etc., can solve the problems of low yield rate and high cost, achieve simplified manufacturing process, increase contact area, and optimize ground clearance The effect of the stripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

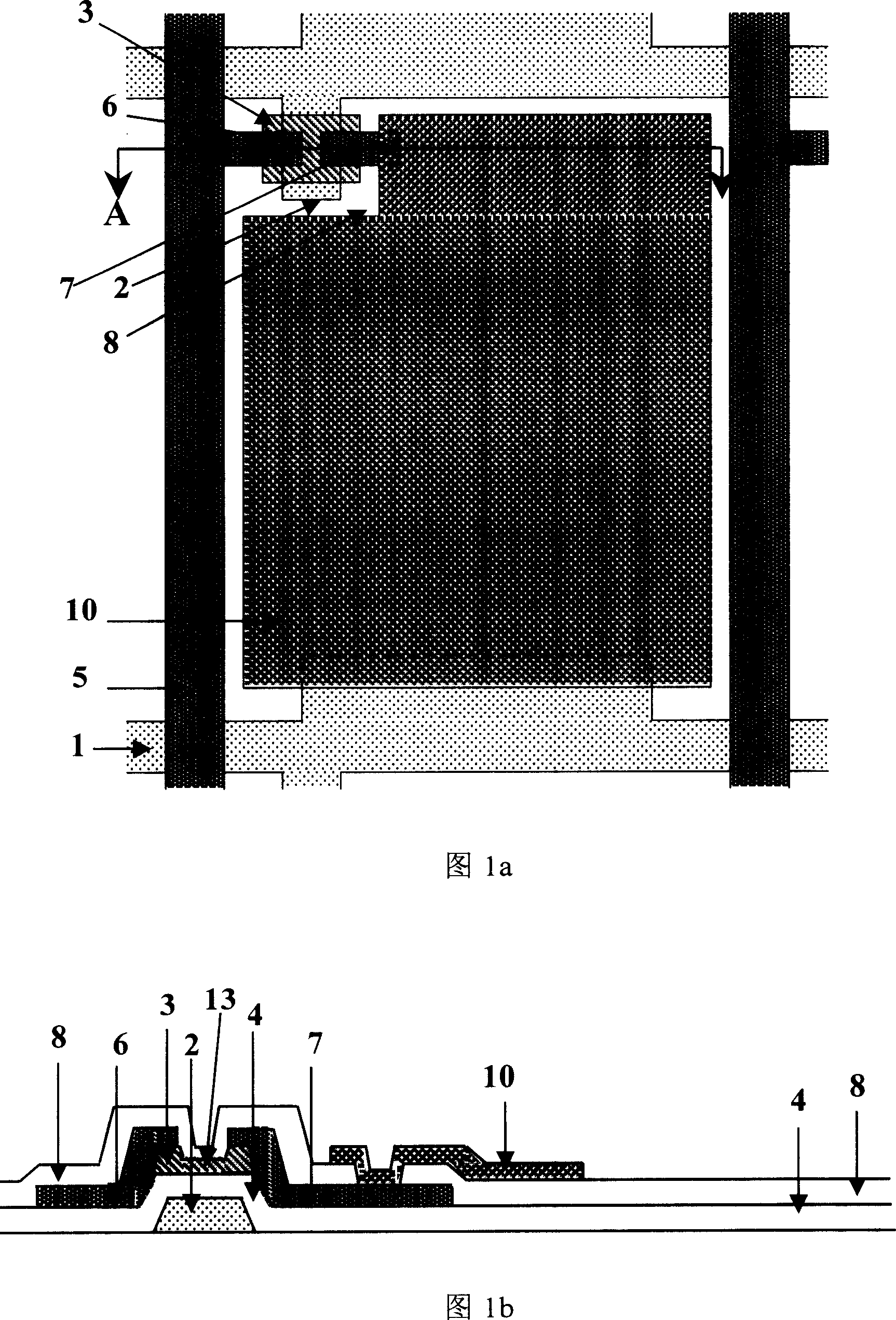

[0034] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

[0035] First, use the first mask plate to form the gate scan line 1 and the gate electrode 2 on the glass substrate: Referring to Figure 5a and Figure 5b, the first mask is formed on the glass substrate by magnetron sputtering or other film forming methods. A layer of metal film, that is, gate metal film. The material of the gate metal thin film may be metals such as molybdenum, aluminum, aluminum-nickel alloy, tungsten, chromium, or copper, or an alloy of the above-mentioned metal materials. In some cases, it can also be a multi-layer film structure, and the material of each layer of film can be selected from the above materials. Next, the first mask is used to form patterns of the gate scan line 1 and the gate electrode 2 through photolithography and etching processes.

[0036] Then, a second mask is used to form patterns of gate insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com