TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array base plate and manufacturing method thereof

A technology of an array substrate and a manufacturing method, applied in the field of a TFT-LCD array substrate and its manufacturing, can solve the problems of different degrees of undercut, cumbersome processing procedures, different degrees of inward inclination of the undercut, etc., so as to improve the yield and simplify the Technological difficulty, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

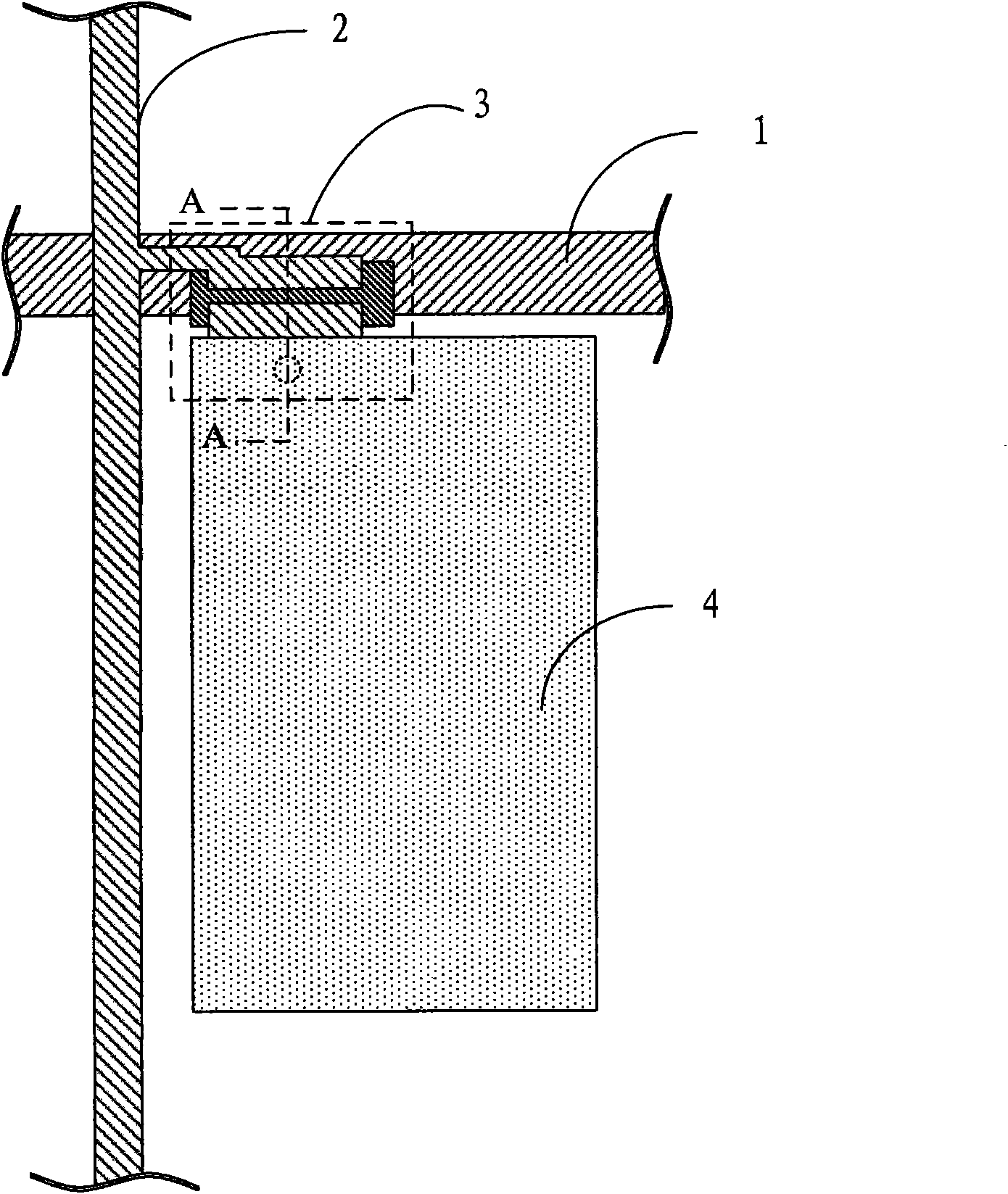

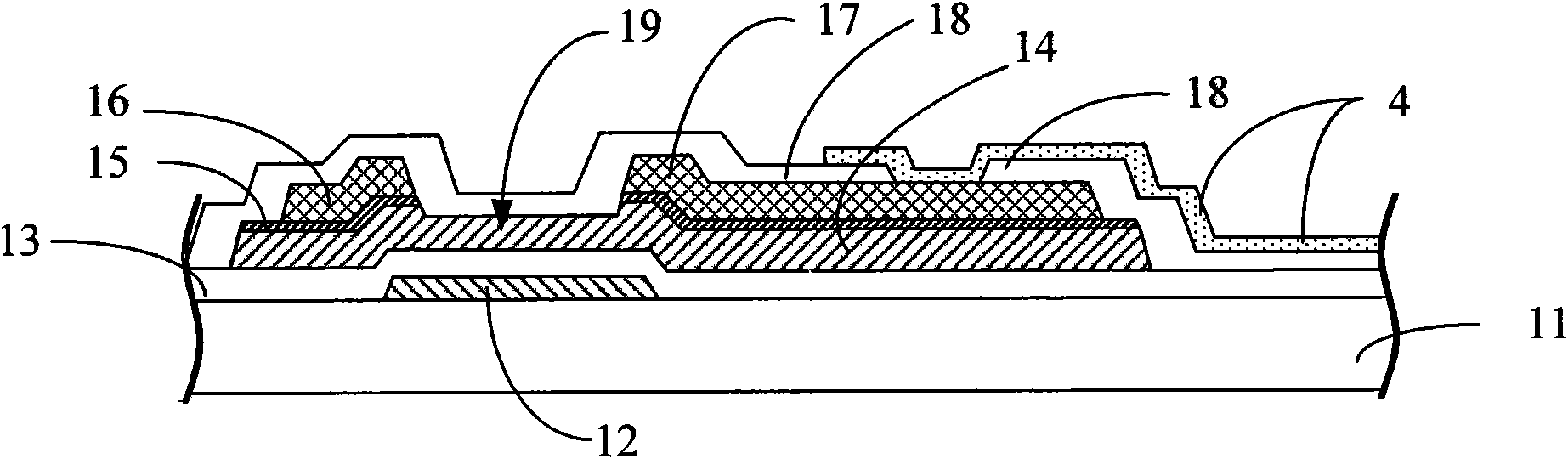

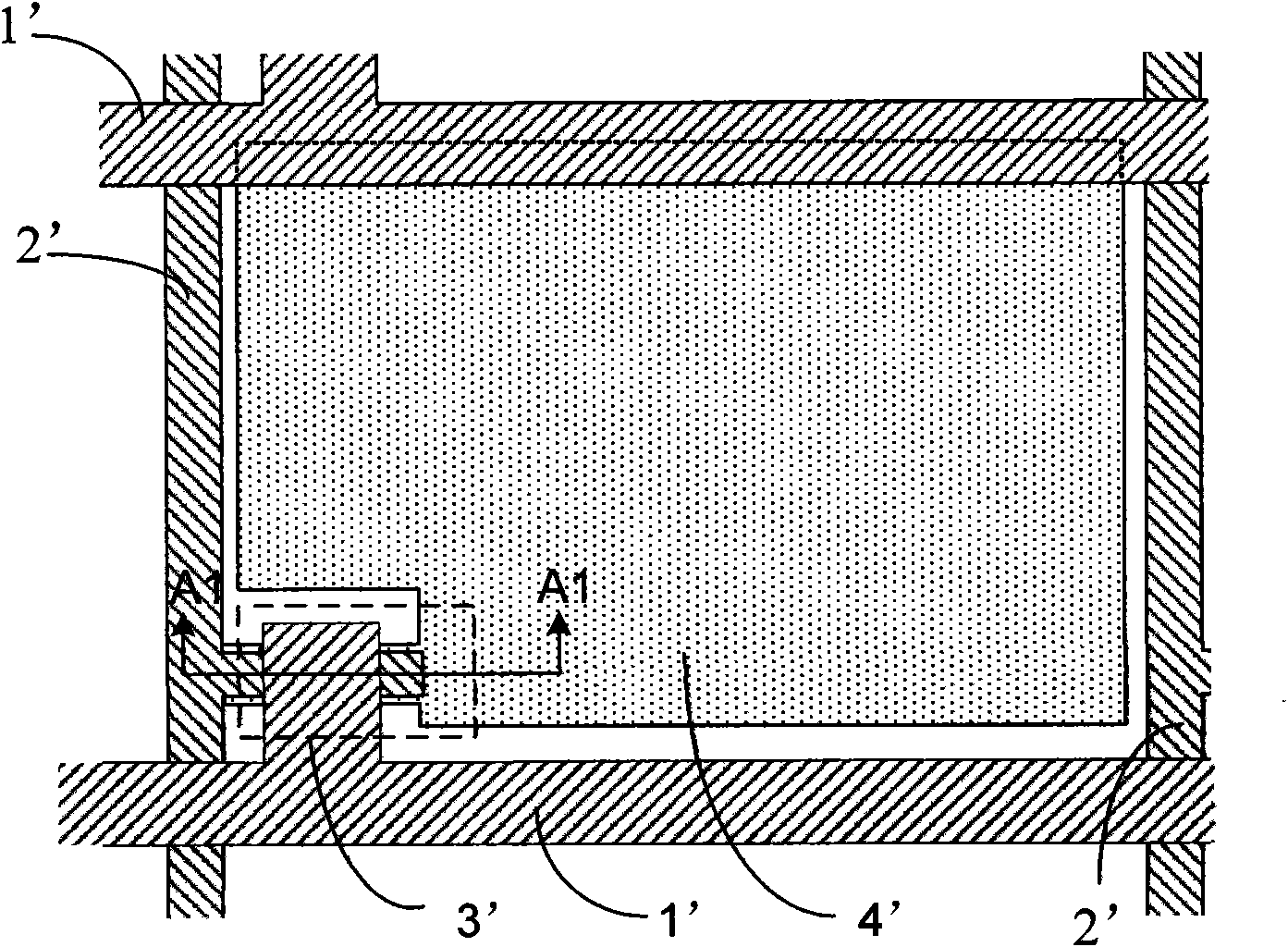

[0041] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0042] It should be noted:

[0043] 1. In the present invention, for example, the "upper" in "X is placed on Y" includes the meaning that X is in contact with Y, and X is located above Y. In the present invention, as shown in the accompanying drawings, the transparent substrate is defined as is set at the bottom;

[0044]2. The patterning process referred to in the present invention includes processes such as photoresist coating, masking, exposure, development, etching, photoresist stripping, and the photoresist is an example of a positive photoresist;

[0045] 3. The "so-and-so area" mentioned in the present invention is the area where a certain figure is mapped on the transparent substrate, that is, the area has the same shape as the certain figure, such as the grid line area, that is, the figure of the grid line is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com