Method for electrochemically preparing MXene

An electrochemical and potentiostatic polarization technology, applied in chemical instruments and methods, inorganic chemistry, electrolytic processes, etc., can solve the problems of difficult to achieve controllable electrochemical preparation of MXene, difficult to achieve large-scale production and application, high risk and Environmental pollution and other issues, to achieve the effect of safe and non-toxic, green preparation and high safety in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

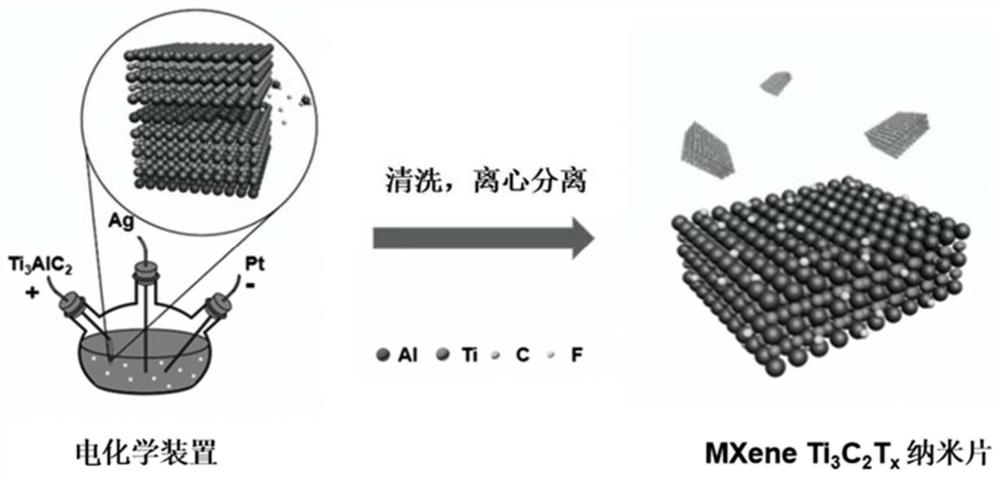

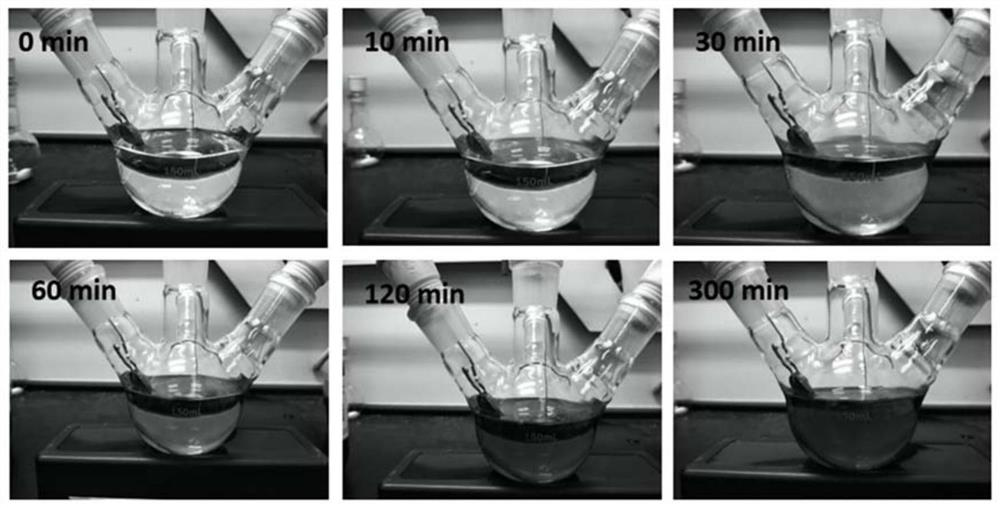

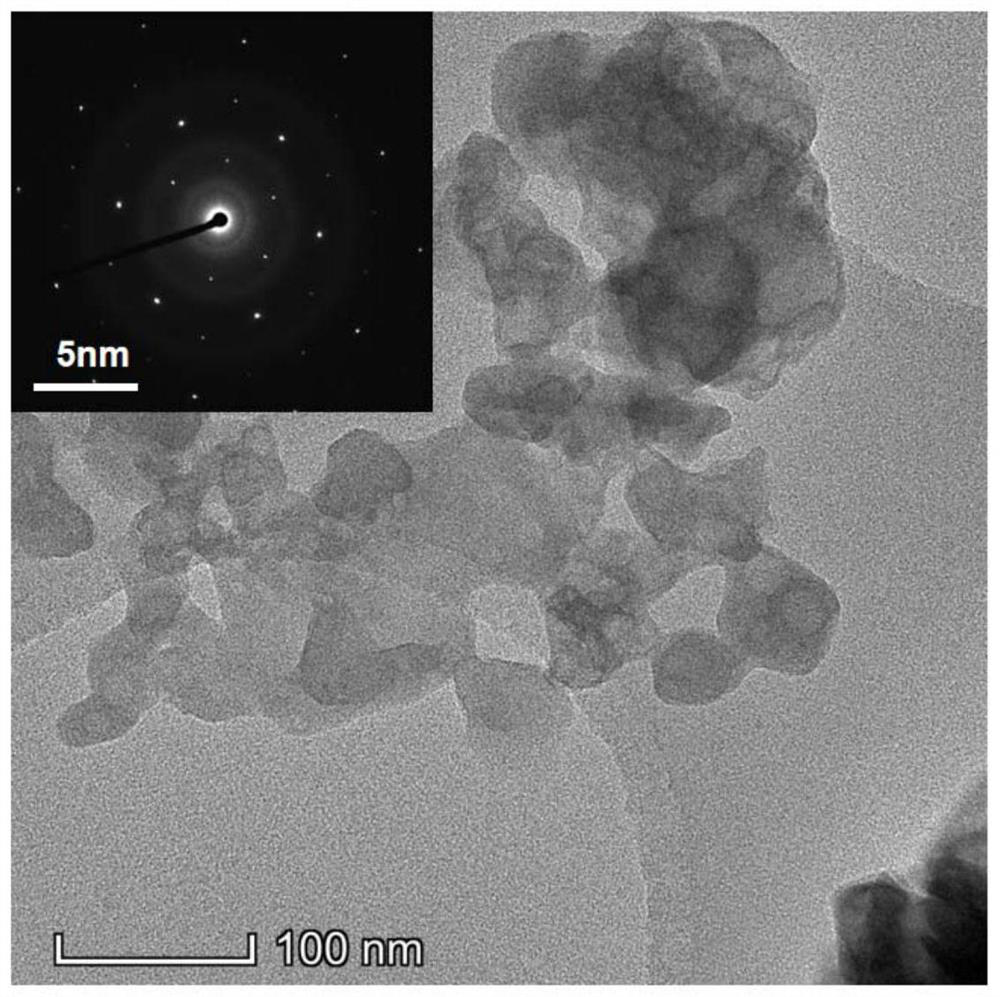

[0079] In this embodiment, an electrochemical method is used to selectively etch Ti 3 AlC 2 Al atomic layer in the preparation of Ti 3 C 2 T x MXene material. Ti 3 AlC 2 The block has good electrical conductivity and meets the requirements of electrochemical stripping for MAX base material. The ionic liquid needs to choose an ionic liquid that can ionize fluorine-containing anions under electrochemical conditions, such as hexafluorophosphate ion, and the higher the ionization efficiency of fluorine-containing anions, the better the electrochemical etching effect, so choose 1-B 3-methylimidazolium hexafluorophosphate as ionic liquid. The concentration of ionic liquid is one of the key process parameters for preparing MXene, and its range is 0.5-5mol / L. In order to improve the efficiency of electrochemical etching and avoid excessive fluorination and etching, it is preferable to select 1mol / L of 1-ethane A solution of 3-methylimidazolium hexafluorophosphate in acetonitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com