Method for heating titanium strip cleaning acid liquor by using microwave heater

A technology of microwave heater and acid solution, applied in the field of microwave heating solution, microwave heater heating titanium belt cleaning acid solution, can solve the problems of rising engineering cost, low heat utilization rate, energy waste, etc., and achieve rapid start and stop, The effect of high energy utilization rate and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

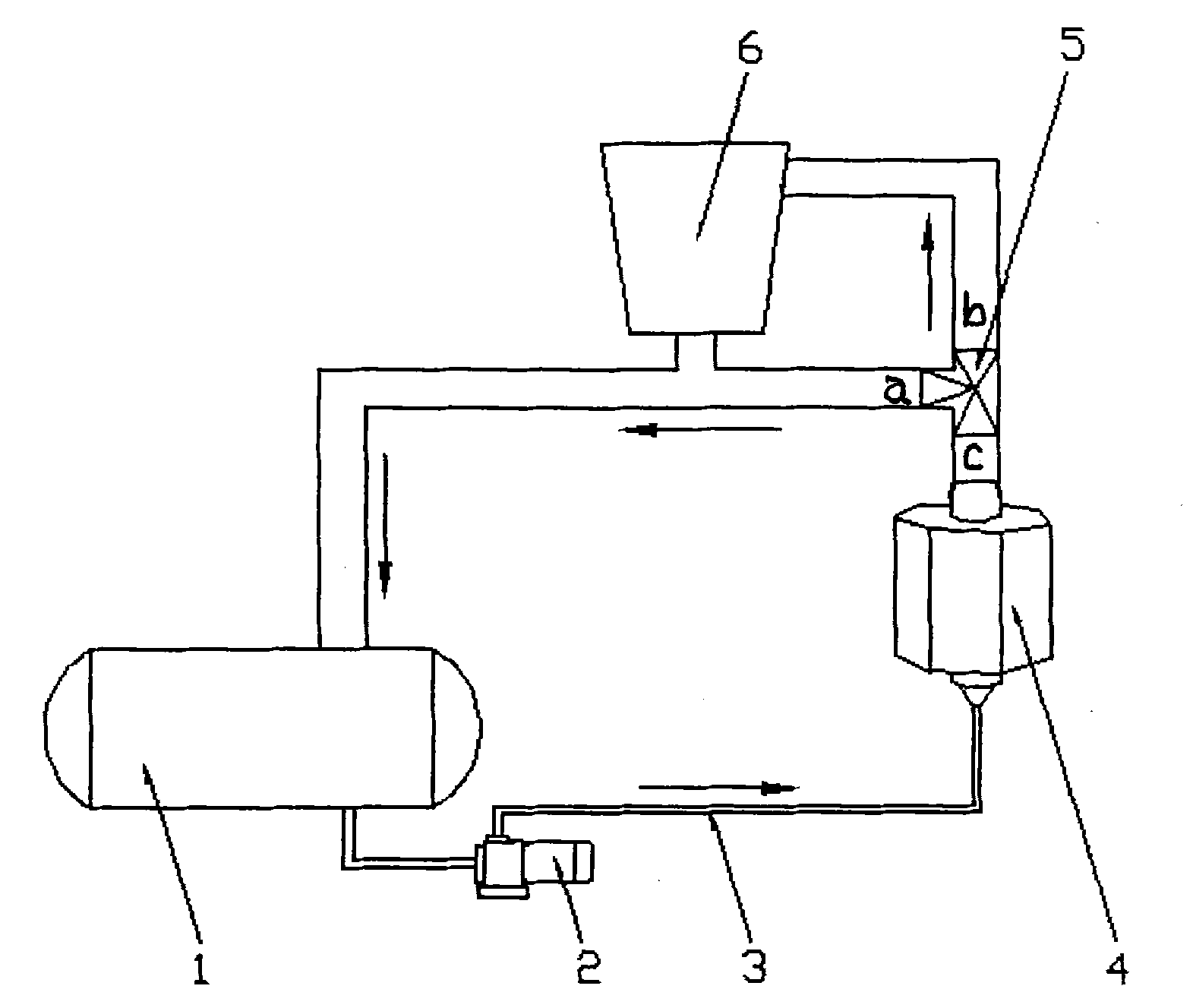

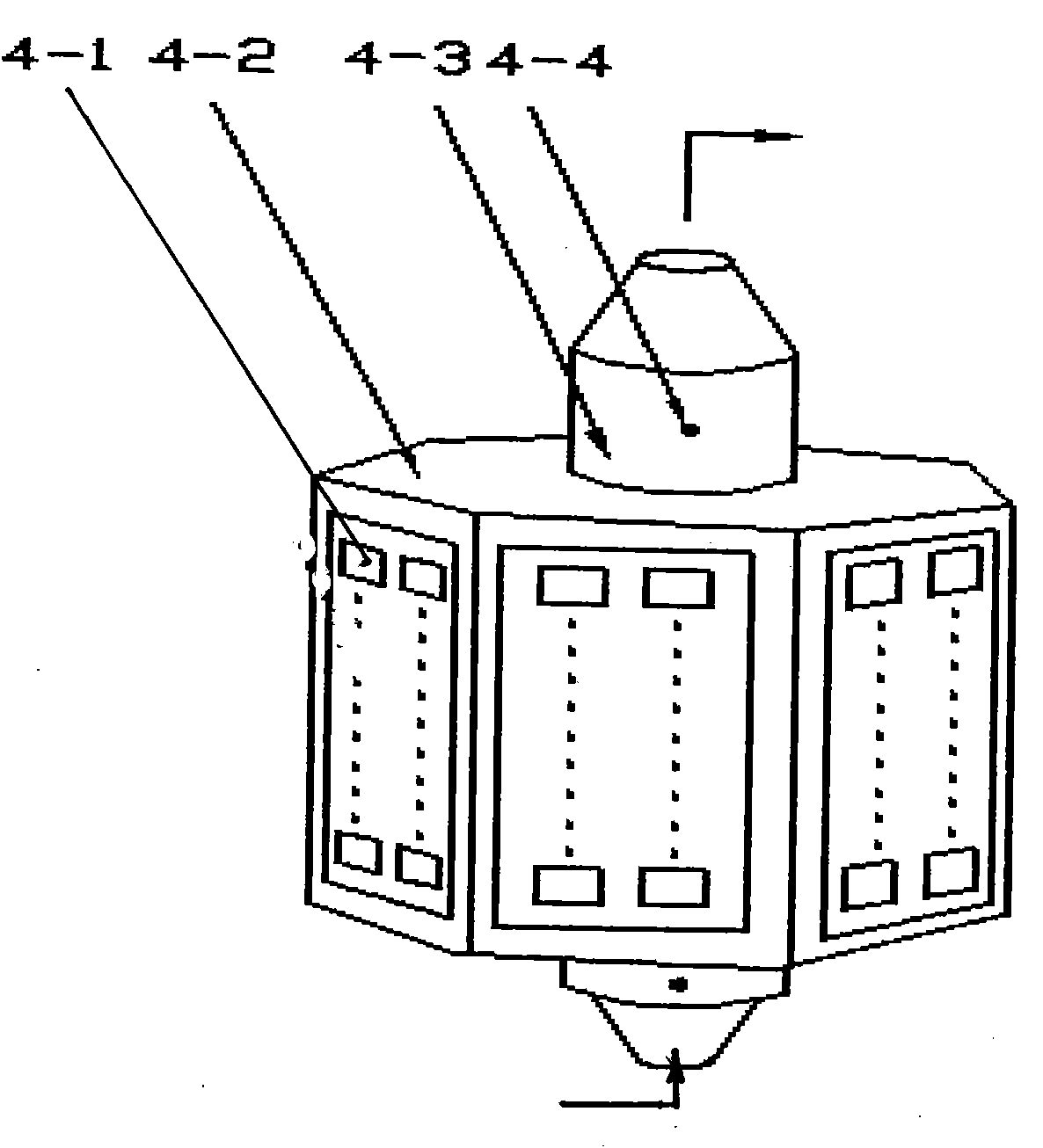

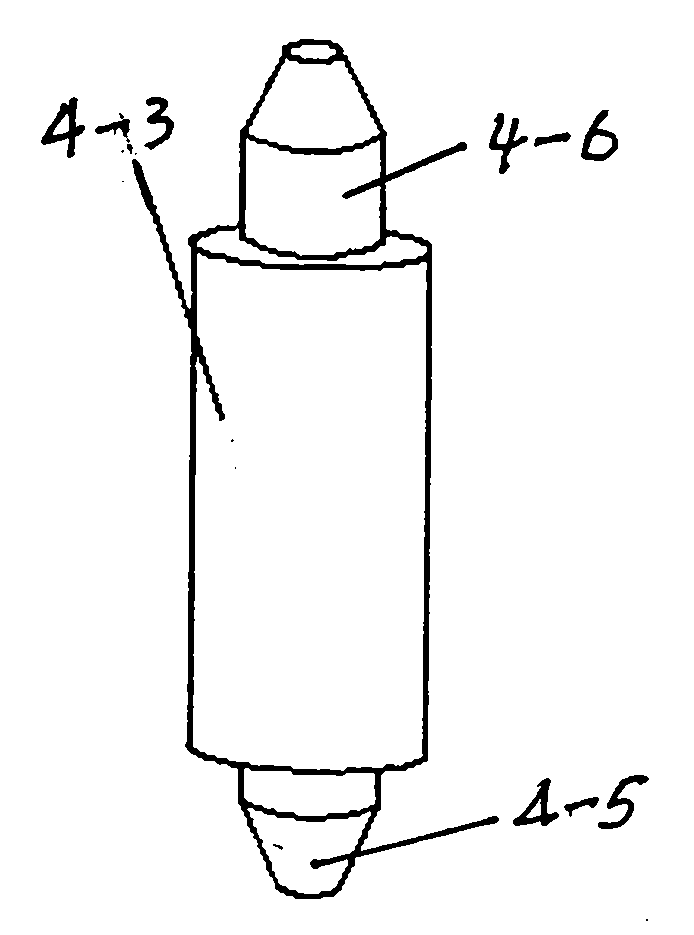

[0017] Embodiment: a kind of method for cleaning acid solution with microwave heater heating titanium belt

specific Embodiment approach

[0018] In actual production, the cleaning acid solution for heating the titanium belt is divided into two stages. The first stage is heating during production preparation, that is, the cleaning acid solution needs to be heated to the temperature required for production before the titanium strip is pickled; the second stage is heating during production, when the titanium strip is pickled, it will Because heat loss cools the acid, the cleaning acid needs to be heated to keep it within the temperature range required for production. The specific implementation is as follows:

[0019] 1. Heating of cleaning acid solution during production preparation

[0020] When the circulation device is working, the circulation pump 2 is turned on, and the acid liquid is continuously extracted from the circulation tank 1. When it flows through the microwave heating equipment 4, it is heated by the microwave heater to raise the temperature. At this time, the a and c directions of the three-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com