Production process and equipment for extracting rosewood essential oil from rosewood chips

A technology for rosewood essential oil and production equipment, which is applied in the directions of essential oil/spice, fat production, etc., can solve the problems of low yield of essential oil products, economic losses, and high production costs, and achieves improvement of the yield and quality of essential oils, reduction of manual operations, and improvement of production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

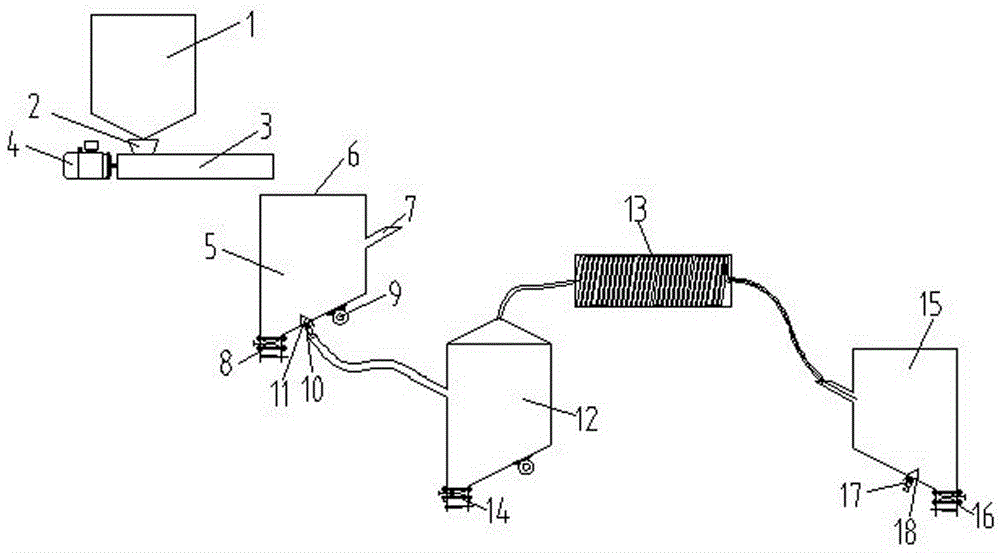

[0018] Such as figure 1 A production process for extracting rosewood essential oil from rosewood sawdust is shown, including the following steps: firstly, rosewood sawdust, water and cellulase are catalyzed in a soaking tank to obtain a liquid, and rosewood sawdust, water and cellulase are mixed in a soaking tank At the same time of catalysis, the ultrasonic vibrator installed on the dipping barrel vibrates the dipping barrel to homogenize the rosewood sawdust and water, and then the liquid is filtered, distilled through the distillation tank, and then transported to the condenser for liquefaction to obtain crude essential oil, and then the crude essential oil is transported to The rosewood essential oil is obtained by extracting petroleum ether extractant in the purification tank.

[0019] The water temperature is 30° C. when the rosewood sawdust, water and cellulase are catalyzed to obtain liquid in the dipping tank. When the temperature of the crude essential oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com