Preparation method of Hastelloy X alloy powder for 3D printing

An alloy powder and 3D printing technology, applied in the field of additive manufacturing, can solve the problems that restrict the development of 3D printing technology and less research, and achieve the effects of avoiding adverse effects, high purity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of Hastelloy X alloy powder for 3D printing technology, comprising the following steps:

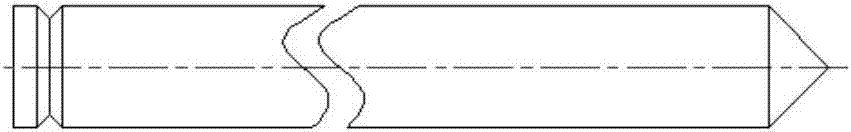

[0029] (1) Bar processing: according to the composition of Hastelloy X, Fe: 17% to 20%, Cr: 20.5% to 23%, Co: 0.5% to 2.5%, Mo: 8% to 10%, W: 0.2% to 1%, C: 0.05% ~ 0.15%, Si≤1%, Mn≤1%, P≤0.04%, S≤0.03%, melting to produce Hastelloy X alloy rods, and then processing the rods, according to the intermediate frequency induction The size of the coil determines the processing diameter of the Hastelloy X alloy bar. It is made into a bar with a diameter of 35-50mm, a length of 500-550mm, a V-shaped notch at one end, and a cone angle of 50°-80° at the other end. Hastelloy X alloy bar The structure after processing is as figure 1 shown;

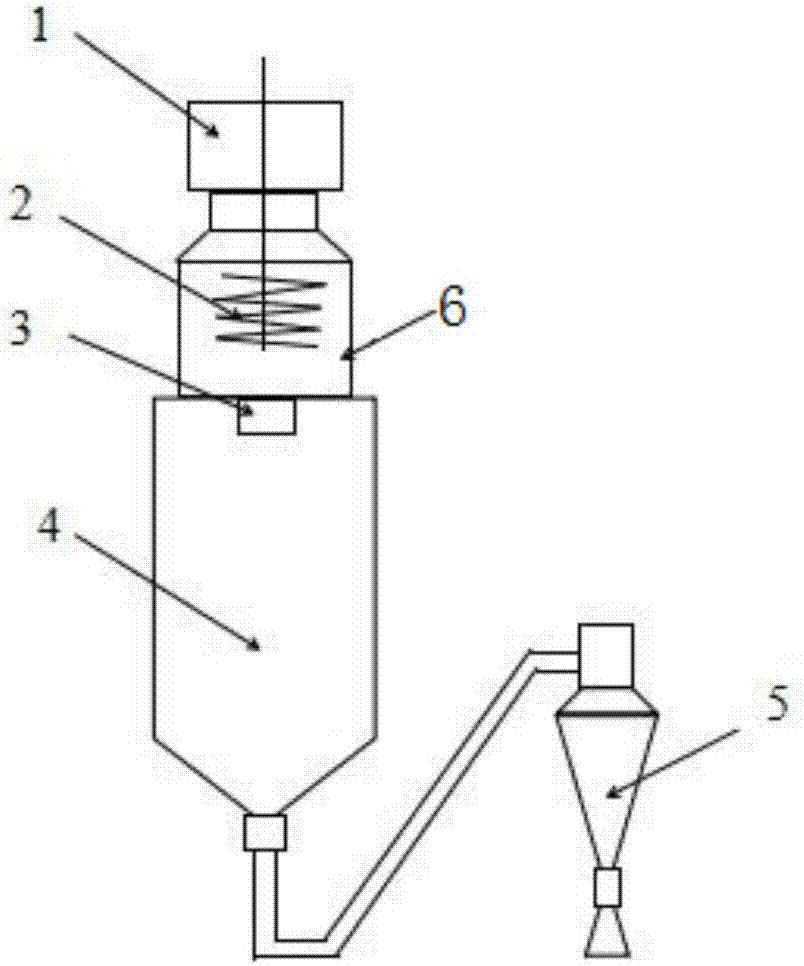

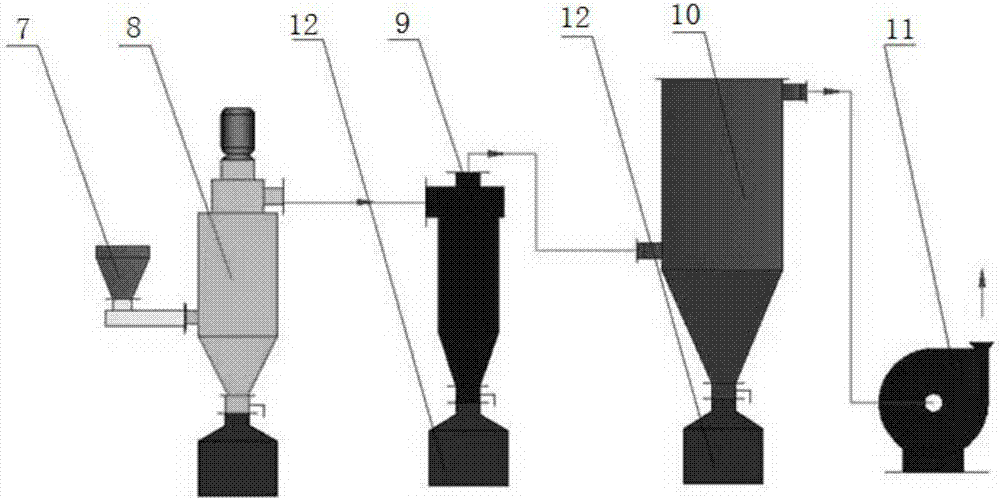

[0030] (2) Smelting and atomizing: equipment for smelting and atomizing pulverization, such as figure 2 As shown, it includes a feeding mechanism 1 arranged up and down, a melting chamber 6 and an atomizing tower 4. The continuous ...

Embodiment 1

[0037] The preparation method of the Hastelloy X alloy powder that is used for laser selective melting technology (SLM), comprises the following steps:

[0038] (1) Bar processing: Process the Hastelloy X alloy bar to make a bar with a diameter of 35mm, a length of 500mm, a V-shaped notch at one end, and a 50° cone angle at the other end;

[0039] (2) Smelting atomization: the processed bar is fixed at the lower end of the feeding mechanism through the clamping mechanism. The alloy bar is lowered, and its tapered part extends into the induction coil; through the mechanical pump and the Roots pump in turn, the melting chamber and the atomization tower are vacuumed, and when the vacuum reaches 10 -2 ~10 -1 Pa, fill the melting chamber and atomization tower with inert gas until the pressure of the melting chamber reaches 10 5 About Pa; turn on the medium frequency induction power supply, heat the bar, the heating power is 40kW, and the bar will merge into liquid droplets or liq...

Embodiment 2

[0046] The preparation method of the Hastelloy X alloy powder that is used for laser stereoforming technology (LSF), comprises the following steps:

[0047] (1) Bar processing: Process the Hastelloy X alloy bar to make a bar with a diameter of 40mm, a length of 550mm, a V-shaped notch at one end, and a 60° cone angle at the other end;

[0048] (2) Smelting atomization: the processed bar is fixed at the lower end of the feeding mechanism through the clamping mechanism. The alloy bar is lowered, and its tapered part extends into the induction coil; through the mechanical pump and the Roots pump in turn, the melting chamber and the atomization tower are vacuumed, and when the vacuum reaches 10 -2 ~10 -1 Pa, fill the melting chamber and atomization tower with inert gas until the pressure of the melting chamber reaches 10 5 About Pa; Turn on the medium frequency induction power supply to heat the bar with a heating power of 20kW. After the bar is melted, it will merge into liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com