Machining center lubricity test system and optimization method

A machining center and lubrication performance technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems affecting the accuracy of machine tools, large thermal errors, and temperature rise of machine tools that affect the stability of motion, so as to reduce pollution, The effect of reducing the cost of use and avoiding unreasonable lubrication quantity settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

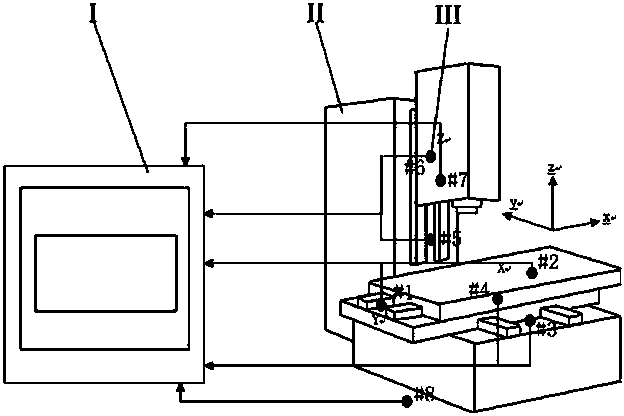

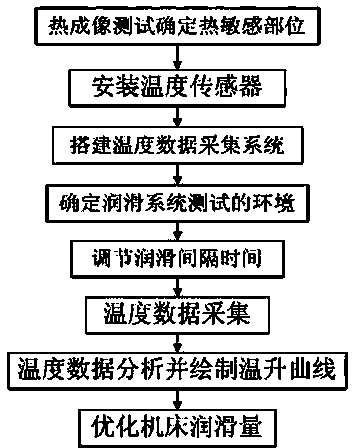

[0029] A machining center lubrication performance testing system, including a temperature sensor, temperature data acquisition and analysis system I, eight temperature sensors III are set, and the temperature sensor III is equipped with a magnetic base, which is magnetically adsorbed on the periphery of the tested machining center II, respectively. Measure the main shaft, X-axis bearing seat, Y-axis bearing seat, Z-axis bearing seat, X-axis nut, Y-axis nut, and Z-axis nut of the machining center II. figure 1 The installation position of each temperature sensor is shown in , and the dots #1~#8 respectively represent the positions: X-axis bearing seat, X-axis nut, Y-axis bearing seat, Y-axis nut, Z-axis bearing seat, Z-axis nut , the spindle and the surrounding environment of the machining center under test.

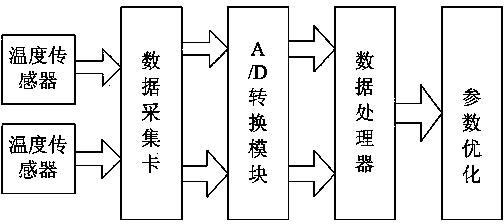

[0030] Among them, the temperature data acquisition and analysis system I is composed of a single-end 32-way data acquisition card, an A / D conversion module and a data pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com