Injection molded steel-tube sea sand recycled concrete column with built-in stiffening member

A technology for recycling concrete and strengthening components, which is applied to columns, piers, pillars, etc., can solve the problems of complex production process, difficult quality control, and increased cost, and achieve the effects of good functional effect, quality control and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

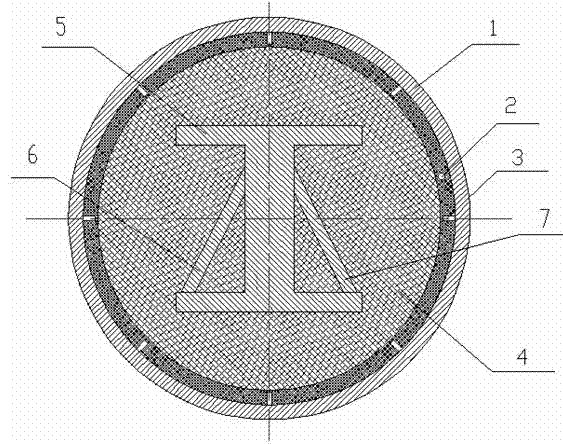

[0013] Attached below figure 1 The description and detailed description further illustrate the present invention.

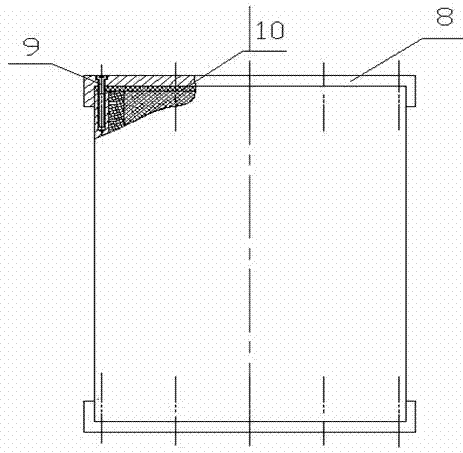

[0014] Such as figure 1 As shown, the injection molded steel pipe sea sand recycled concrete column member includes an injection molded steel pipe, wherein the injection molded steel pipe is filled with sea sand recycled concrete 4, the two ends of the injection molded steel pipe are provided with end caps 8, and the sea sand recycled concrete 4 An FRP steel reinforcement member is also placed, and the built-in FRP steel reinforcement member can improve the mechanical performance of the steel pipe sea sand recycled concrete.

[0015] In this embodiment, the FRP-shaped steel reinforcing member includes FRP I-shaped steel 5, left FRP steel reinforcing bar 6, right FRP steel reinforcing bar 7, and the left FRP steel reinforcing bar 6 and right FRP steel reinforcing bar 7 are respectively fixed on the FRP Both sides of I-shaped steel 5. The FRP-shaped steel reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com